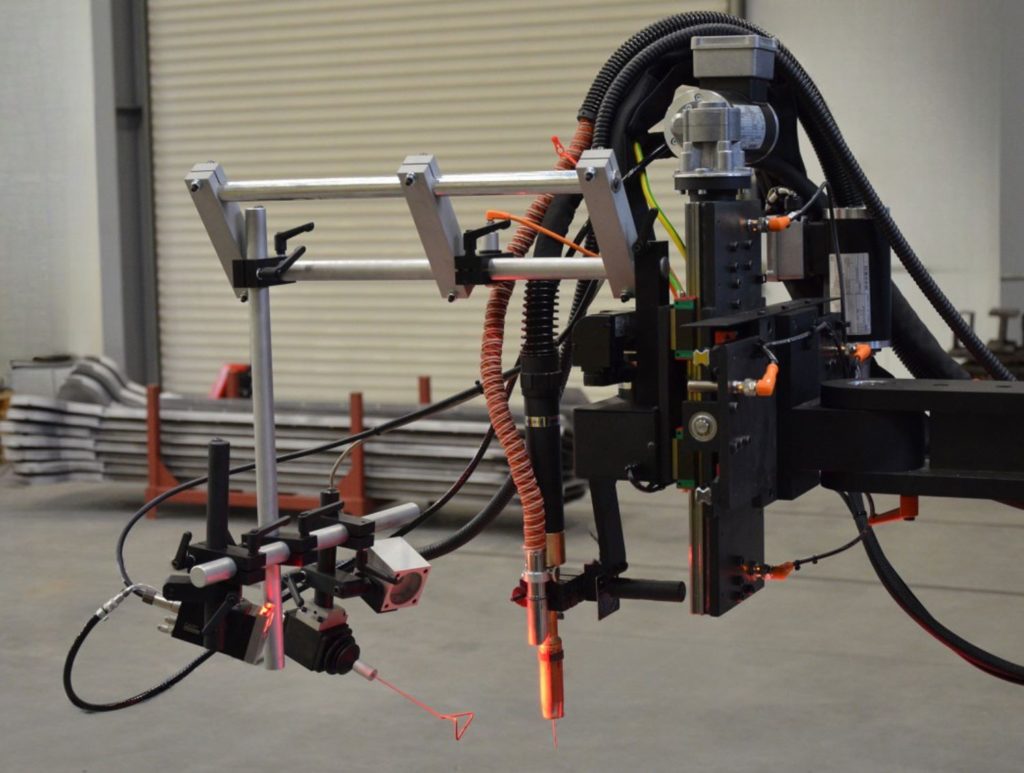

Automated solution for precise welding torch positioning

The Automatic Joint Tracking System (JTS) is an automated solution for precise welding torch positioning in two axes (up-down ↕️, left-right ↔️). JTS is primarily used to compensate for misalignment or curvature in the workpiece. Since the workpiece is not always positioned perfectly parallel or may have irregularities, Joint Tracking System continuously tracks the joint and ensures that the weld seam is placed exactly where it should be. This eliminates the need for manual torch adjustments, improving precision and consistency in the welding process.

Compatible with MIG/MAG and SAW welding, the Joint Tracking System (JTS) seamlessly integrates with any existing or new column & boom, gantry welding system, or custom-built welding setup, ensuring precise torch positioning and consistent weld quality.

The cross-slide unit mounting plate features multiple hole patterns, allowing for flexible installation with various welding machines. This design ensures easy integration with an existing welding system.

For more advanced process control, JTS can be integrated with the main welding device’s safety system, Then JTS can transmit key signals to the primary system (e.g. Column & Boom), providing information such as:

- sensor tension in the X and Z axes (analogue voltage),

- reaching the end of the tracking range (potential-free contact),

- and giving the possibility of integration safety systems (e-stops).

This setup ensures seamless communication between JTS and the welding system, enhancing operational safety and efficiency.

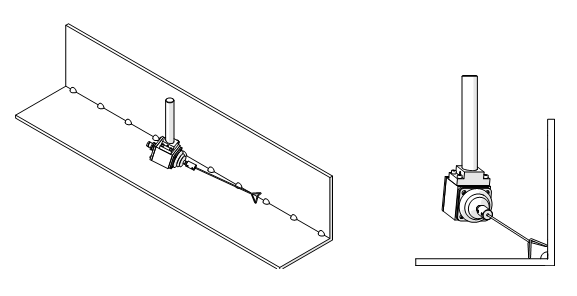

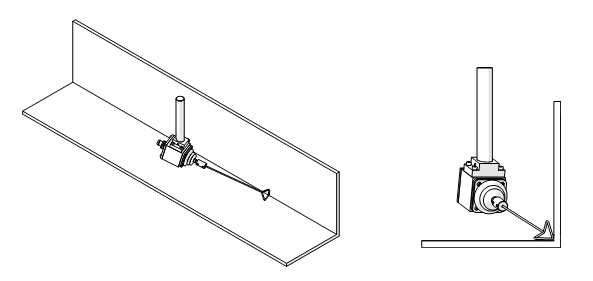

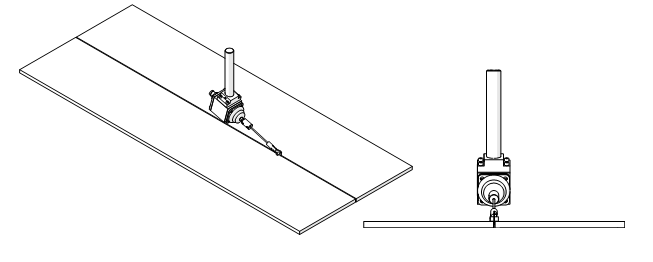

Various tips for tracking system

The range of interchangeable sensor tips allows precise alignment with different weld groove types, ensuring highly accurate and reliable seam tracking across various welding applications.

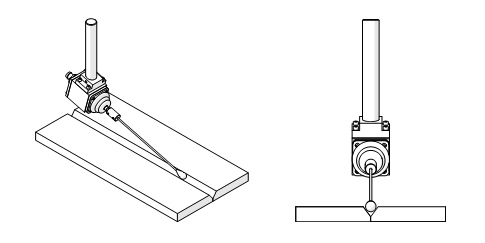

Ball tip

Used for tracking of butt and fillet welds without tacking. The geometry of joint pre-paired for welding must allow for stable ball movement.

Fork tip

Used for tracking of fillet welds with or without tacking and for multi-pass welding.

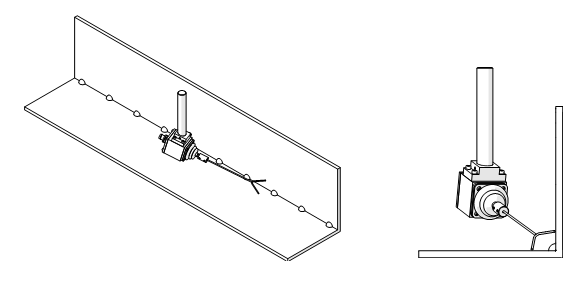

Bent tip

Used for tracking of fillet welds with or without tacking.

Adapter tips

Used for tracking of butt welds of small dimensions not allowing for using the ball tip. In such case no tacking should be used.

How does Joint Tracking System work?

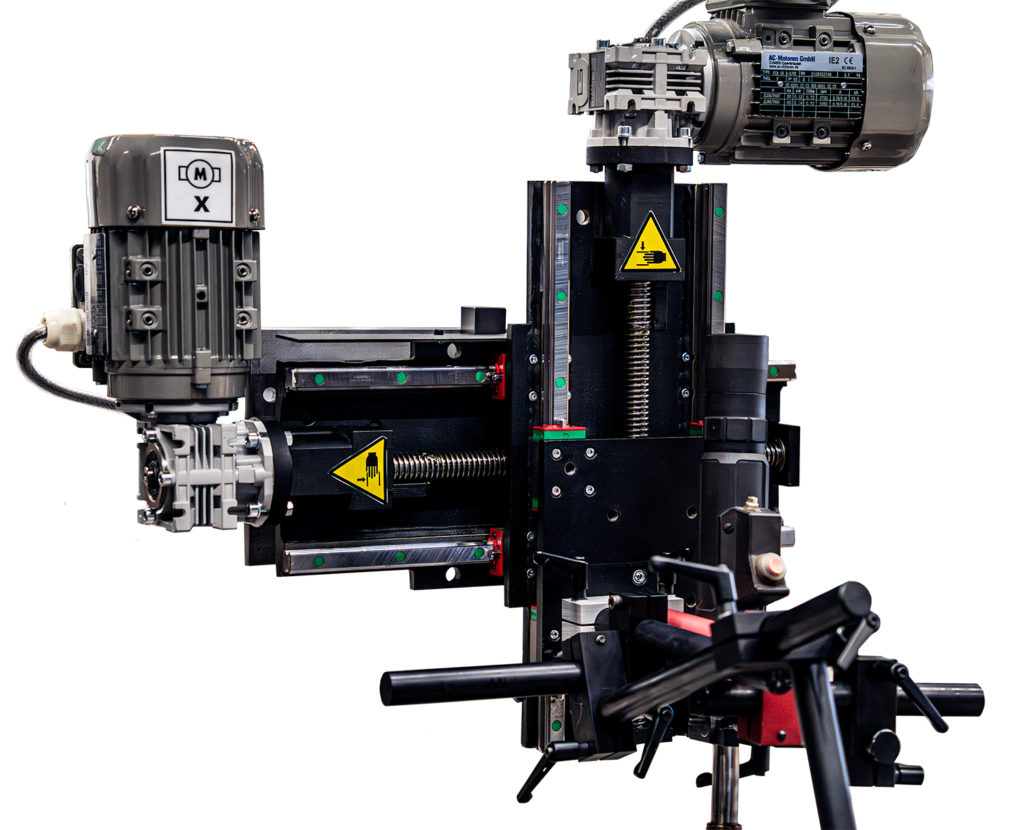

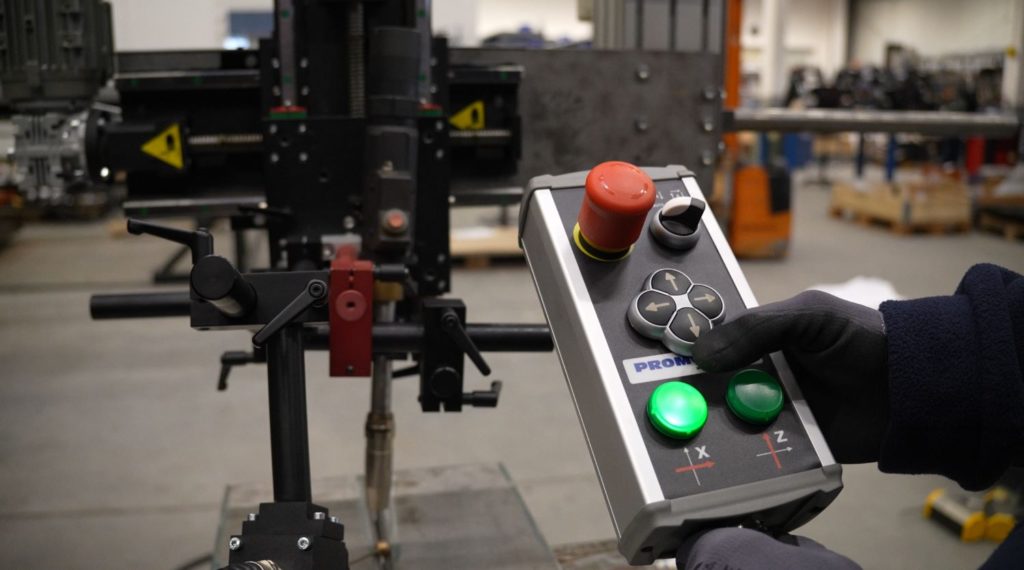

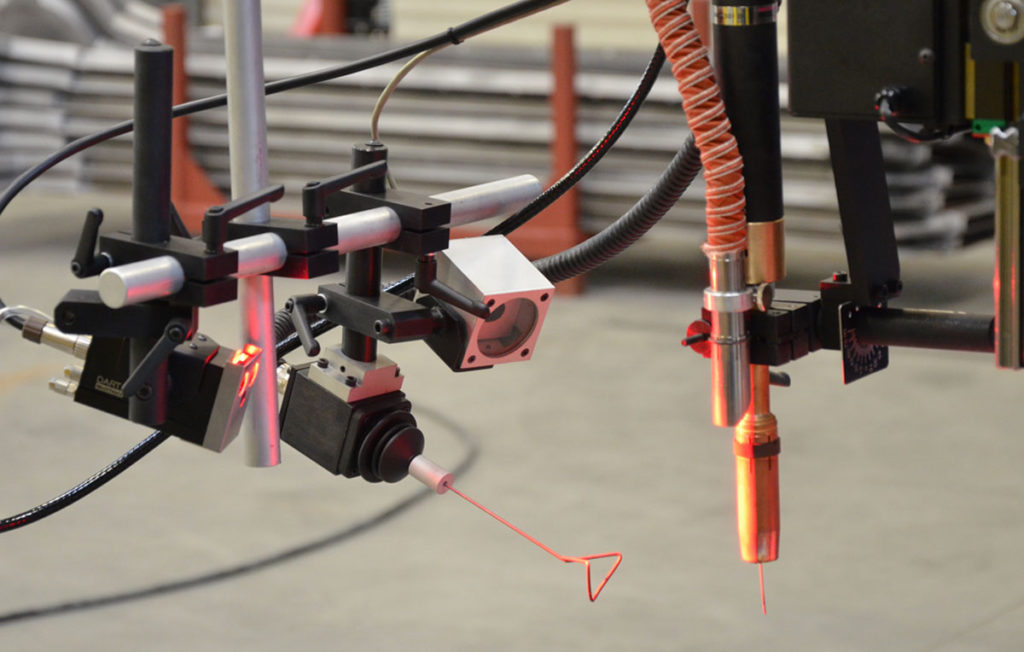

The Automatic Joint Tracking System JTS 200×200 system is composed of a cross slide unit, a high-precision tracking sensor, a control cabinet, an intuitive control pendant, and a set of cables and mounting components. Both axes move on linear guides and are driven by trapezoidal screws, ensuring smooth and stable movement for accurate and repeatable torch positioning.

The operator positions and pre-tensions the tip of the electromechanical two-axis sensor within the welding groove. During the welding process, the sensor continuously detects deviations in the groove’s trajectory and automatically adjusts the welding torch to maintain its pre-set position relative to the welding joint.

By delivering real-time trajectory correction, JTS keeps the torch in the correct position relative to the welding material. This minimizes welding defects and reduces the need for post-weld grinding.

- Power 500 W

- Horizontal movement range (X axis): 200 mm (7.9″)

- Vertical movement range (Z axis): 200 mm (7.9″)

- Max vertical movement speed (Z axis): 360 mm/min (14.2 in/min)

- Max horizontal movement speed (X axis): 360 mm/min (14.2 in/min)

With a standard range of motion of 200 x 200 mm, the Automatic Joint Tracking System provides great flexibility in terms of range of motion and adaptation to the weld joint track. The movement range can be customized upon customer’s request.

Three modes to choose from

Automatic Joint Tracking System (JTS) operates in three modes:

- manual,

- automatic vertical,

- and automatic horizontal and vertical.

In manual mode, the operator precisely controls the movement of both the X and Z axes using arrow buttons on the control pendant. The automatic vertical mode enables real-time tracking along the vertical axis, adjusting the torch height for optimal positioning. The automatic horizontal and vertical mode provides full seam tracking in both axes.

Wide Range of Industrial Applications

Automatic Joint Tracking System is ideal for fillet and butt welding in tanks, vessels, structural beams, as well as the production of pipes, wind towers, and construction beams. Suitable for both longitudinal and circumferential welding applications.

For even greater versatility, the JTS 200×200 can be seamlessly integrated with welding oscillators, such as OSC-8 pendulum weave welder, expanding application possibilities for high-precision, automated welding.