Drilling holes in pipes and tubes

Drilling holes in a pipe using mag drill is an operation that requires the right set of tools. The curved surface of the pipes forces to apply a suitable solution.

Drilling holes in metal pipes is a common operation in various industries, it requires high accuracy and safety. Annular cutters (also known as crown bits) are recommended for making holes in curved surfaces. Their construction allows an even and stable penetration through the curved surface of the pipe. Due to the fact that the material is gradually cut out after the circumference of the wheel, the drill evenly penetrates into the material. When drilling in pipes, one should also remember about the coolant. It will effectively extend the life of the drill bit and the quality of the surface being machined.

In the case of drilling holes in pipes, stability is critical. A rigid arbor and permanent magnetic base of mag drill equipped with an annular cutter are optimal set for a rounded surface. But to safely start drilling on the pipe or tube, a special clamping device is needed

How to drill hole in metal tube or pipe?

For drilling holes in pipes made of magnetically responsive materials, the optimal solution is to use a mag drill equipped with a base adaptable to the curved surface.

The base includes two or even four separate permanent magnets whose position (tilt) can be adapted to different tube radii (PRO-36 MS, PRO-200A ATEX). What’s more, the magnets in the base of the drill are not electrically powered so the motor uses the total power of the machine. Thanks to the permanent magnets, the drill will hold onto the pipe in the event of a power outage, making a significant contribution to work safety. Existing solutions allow drilling outside of pipes and inside large pipes.

How to drill holes in tube or pipe using a drill with typical flat electromagnetic base?

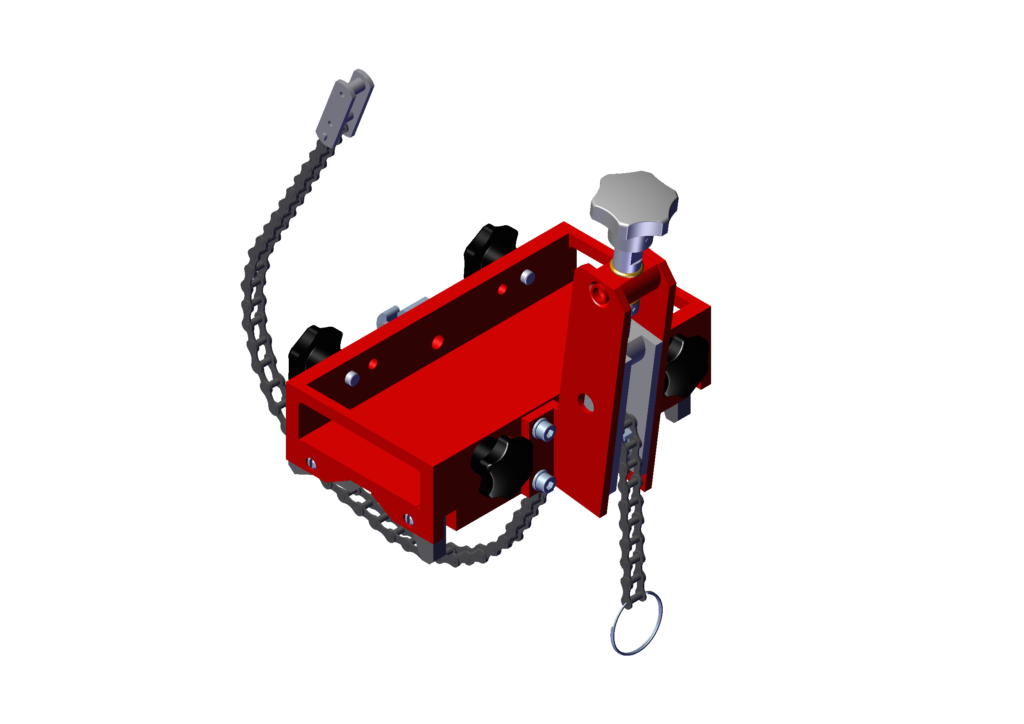

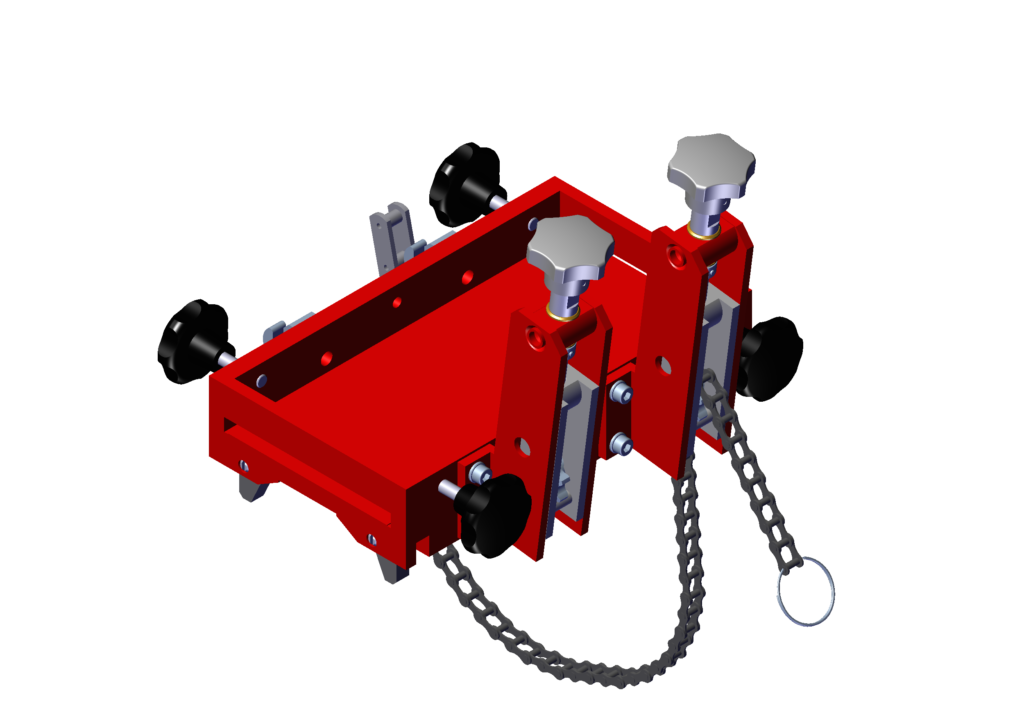

If you do not have a drill with a specially shaped base to attach directly to a pipe or tube, you can use a chain attachment. This simple accessory allows virtually any drill with a magnetic base to be used on the pipe surface.

Manufacturers offer different sizes of attachments (e.g. DMP-251, DMP 501), so that almost any mag drill can be used to pipe drilling. The attachment is equipped with a long chain, the length of which can be adjusted, allowing drilling into pipes with a wide range of external diameters (e.g. between 80 mm and 250 mm for DMP-251 and between 150 mm and 500 mm for DMP-501).

An additional advantage of the chain attachment is that a drill with a typical flat electromagnetic base can be attached also to pipes or tubes made of non-ferromagnetic materials.