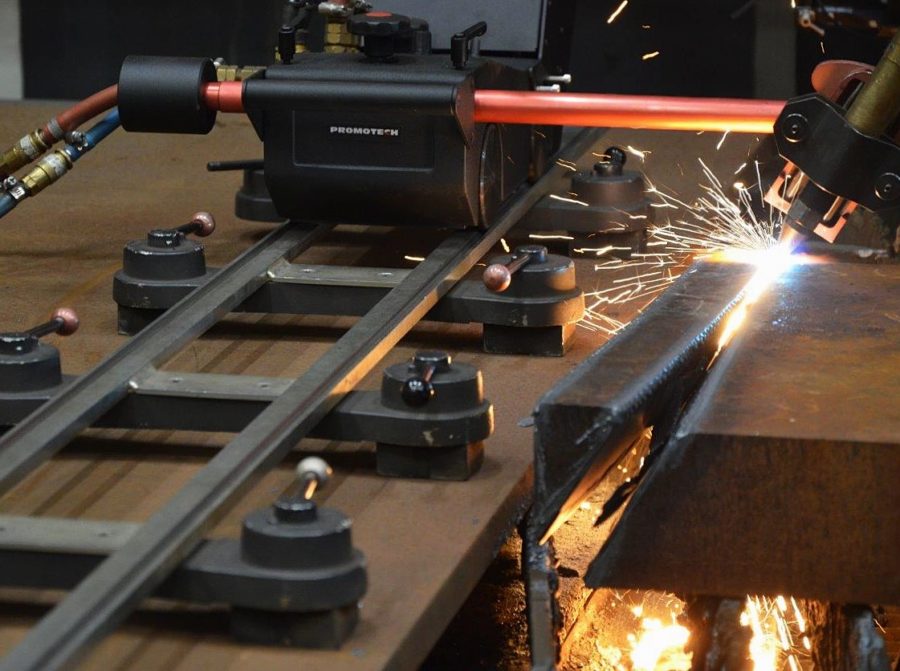

The right tools for Stainless Steel bevelling

Due to its hardness and lower thermal conductivity, stainless steel bevelling requires specialized tools – a beveller that is powerful enough to cut through it smoothly. It can be a machine dedicated specifically to that task or a powerful and durable beveller that with a little adjustment or the use of accessories can also deliver excellent results, handling the material’s toughness without breaking down or overheating.

In general, compared to other metals, stainless steel requires slower cutting speeds to avoid work hardening and excessive tool wear. As it has poor thermal conductivity, heat buildup during machining can be problematic. To reduce heat and prolong tool life, it is important to use coolants like water-soluble oils, lubricants, or synthetic coolants.

Read more about Stainless Steel properties in the previous article >>

Depending on the task, desired bevel’s width, and a type of application one can choose a suitable machine from PROMOTECH’s portfolio. There is a wide variety of bevellers that feature speed adjustment and stainless steel parts, making them suitable for processing stainless steel. These include the BM-18 multitask beveller, its pneumatic version BM-18A, as well as portable pipe bevellers PRO-2 PB, PRO-5 PB, PRO-10 PB, and auto feed plate bevellers ABM-14, ABM-28, ABM-29, ABM-50, or upcoming soon new model ABM-50 DD Vario. There is also the stationary bevelling machine SBM-500.

Please check the table below to find out the most suitable configuration for bevelling stainless steel.

| Machine Name | Tool type |

| BM-18 | Multitask Plate and Pipe Beveller | NKL-0509-05-00-00-0 |

| BM-18A | Pneumatic Plate Beveller | NKL-0509-05-00-00-0 |

| BM-21S | Stainless Steel Plate & Pipe Beveler | Ready to use with SS |

| BM-25 | Plate Beveling Machine | ZST-0715-24-00-00-0 set |

| BM-25S | Stainless Steel Plate & Pipe Beveller – NEW | Ready to use with SS |

| ABM-14 | Plate and Pipe Beveler | FRZ-000588 |

| ABM-28 | Auto Feed Plate Beveler | PLY-00835 |

| ABM-29 | Industrial Shearing Beveller – NEW | FRZ-000599 |

| ABM-30 | Auto Feed Trackless Beveller | ZST-0690-16-00-00-0 set |

| ABM 50 | Auto Feed Bevelling Machine | PLY-00835 |

| ABM 50 DD / DD VARIO | Auto Feed Bevelling Machine | PLY-00835 |

| SBM-500 | Stationary Bevelling Machine | PLY-00835 |

| PRO 2 PB | Compact Pipe Beveler | Use Titan coated toolbit |

| PRO-5 PB | Portable Pipe Beveler | Use Titan coated toolbit |

| PRO-10 PB | Portable Pipe Beveler & Flange Facer | Use Titan coated toolbit |

| PRO-40 PBS | Stationary Pipe Beveling Machine | PLY-00835 |

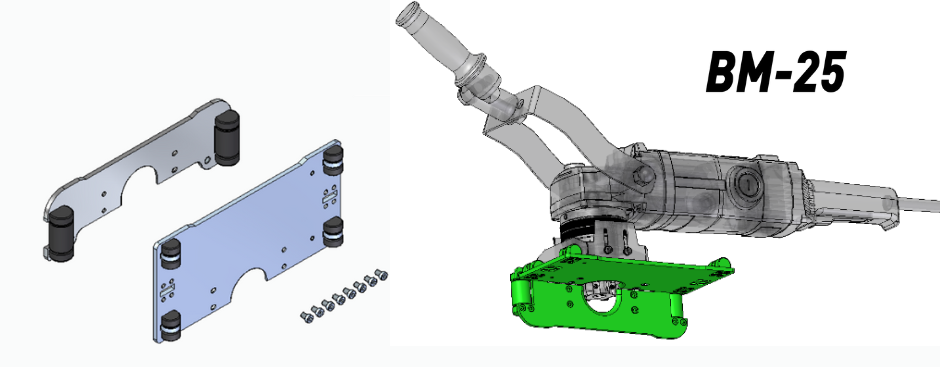

In PROMOTECH offer one can also find bevellers that need extra accessories to deliver excellent performance on stainless steel, like renowned BM-25 and ABM-30. It is discussed in detail below.

PROMOTECH’s bevelling machines range is completed with dedicated machines designed and produced specifically for stainless steel materials, namely the BM-21S and BM-25S Stainless Steel Plate & Pipe Bevellers.

BM-21S Stainless Steel Plate & Pipe Beveler is equipped with a low-speed motor is suitable for milling stainless steel plates and pipes. It can perform bevels up to 21 mm and allows continuously adjustable bevel angles from 0° up to 60°. Monobloc milling head equipped with 10 square inserts to make the machining process far more efficient and much less operator fatiguing. Guide plate with rolls made of stainless steel protects the workpiece from contamination.

Read more about BM-21S >>

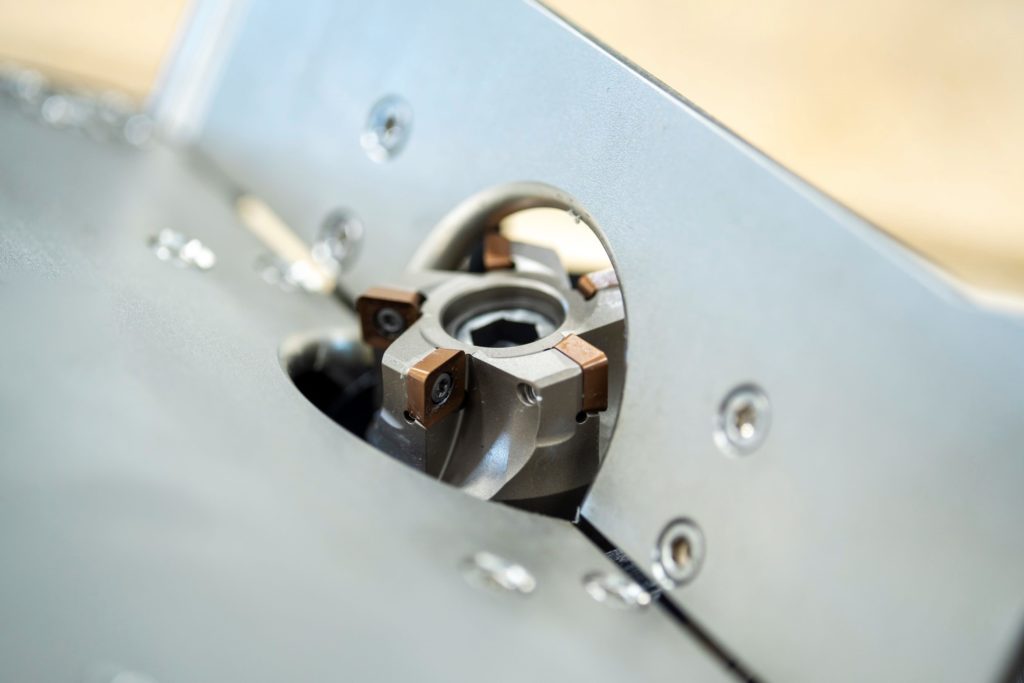

BM-25S Stainless Steel Plate & Pipe Beveller is an easy-to-use, portable heavy-duty machine designed to machine stainless steel. The beveller is equipped with a powerful motor and fitted with face milling beveling head allowing smooth operation and exceptional efficiency. Continuously adjust bevel angle and milling depth for full control of the milling process. All components of the guide are made of stainless steel to protect against contamination.

For external bevelling of pipes made of stainless steel with a minimum diameter of 100mm (4”) use a dedicated set, Product code: ZST-0715-24-00-00-0.

Read more about BM-25S stainless steel beveller >>

How are BM-25 and ABM-30 bevellers prepared for stainless steel bevelling?

BM-25 and ABM-30 bevellers accept the same milling head, equipped with five 4-sided indexable cutting inserts specifically customized for stainless steel machining.

Both bevelling machines feature a powerful motor with electronic speed control, working between 1800 and 5850 rpm, allowing adjusting the speed to the specific grade of stainless steel workpiece material. This flexibility helps to achieve optimal cutting performance and reduces the risks of overheating and material or tool damage.

Through continuous adjustment of milling depth, bevel width, and bevel angle, BM-25 and ABM-30 provide good control over the bevelling process. Whether you need precise cuts or wider bevels, the BM-25 and ABM-30 bevelling machines deliver consistent, high-quality results, making them excellent choices for stainless steel applications.

Bevelling Stainless Steel with BM-25

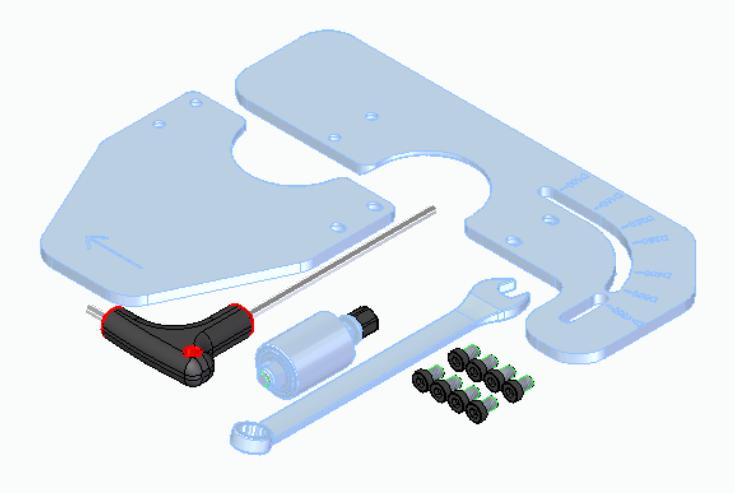

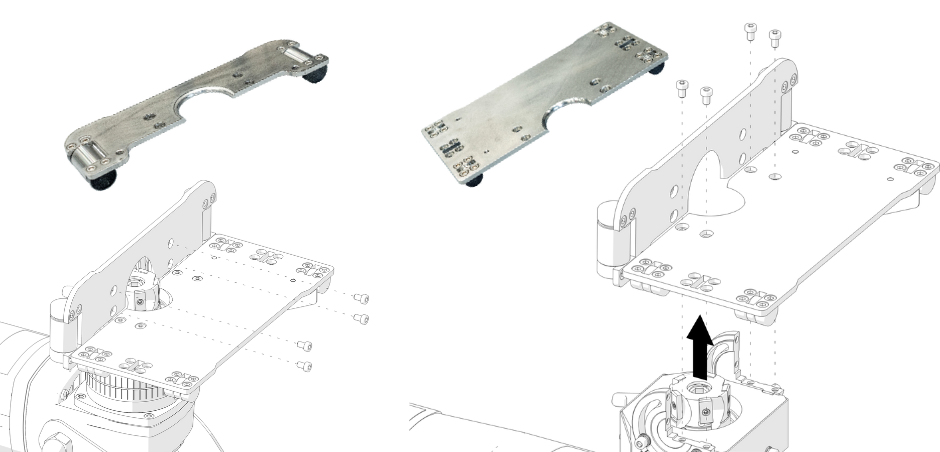

BM-25 is capable of creating maximum 25 mm wide bevel on stainless steel in several passes. Before starting work with a standard BM25 machine its regular parts such as milling head, cutting inserts, and guide slides with rollers must be replaced with their stainless steel-dedicated equivalents. They can be replaced quickly and easily.

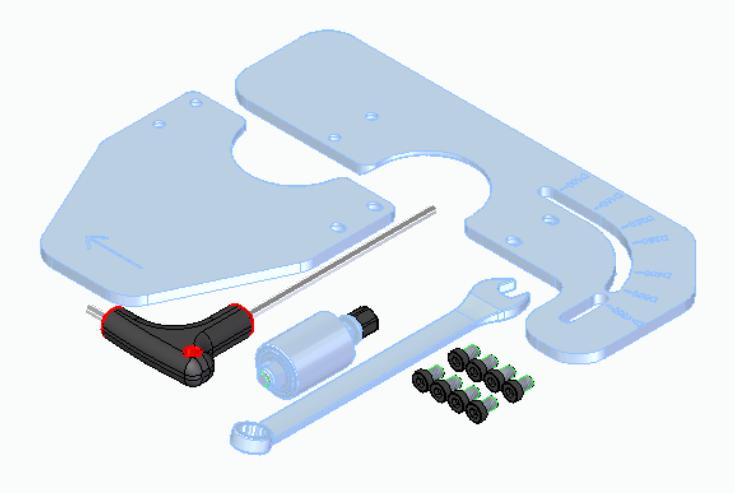

Dedicated Stainless Steel set for BM-25:

• 2 roller guides with bearings made of AISI 304

• all mounting screws made of AISI 304

Product code: ZST-0715-24-00-00-0

Dedicated set for BM-25 for Stainless Steel pipe bevelling with a minimum diameter of 100mm:

Product code: ZST-0715-24-00-00-0

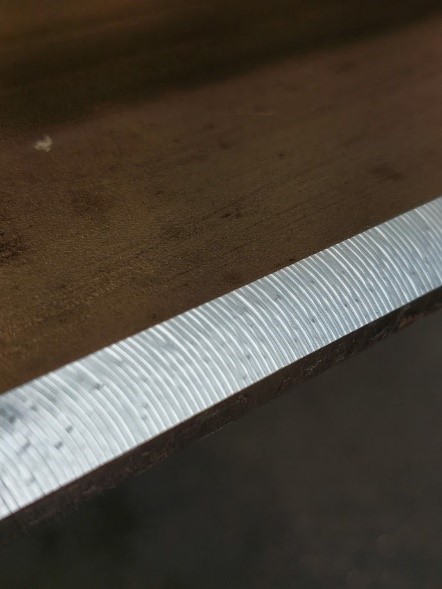

Compared to other metals stainless steel requires slower cutting speeds to prevent work hardening and reduce excessive tool wear. Gradually increase the head penetration into the material to enlarge bevel width step-by-step.

| BM-25 – recommended steps in bevelling stainless steel | ||

| Pass no. | Max. In-depth progress of milling head [mm] | Bevel width obtained [mm] |

| 1st | 3.0 | 6.0 |

| 2nd | 2.3 | 10.6 |

| 3rd | 2.0 | 14.6 |

| 4th | 1.6 | 17.8 |

| 5th | 1.4 | 20.6 |

| 6th | 1.2 | 23.0 |

| 7th | 1.0 | 25.0 |

The BM-25‘s powerful motor with electronic speed control between 1800 –5850 rpm enables it to adapt to different material properties, manage temperature, extend tool life, and achieve high-quality finishes.

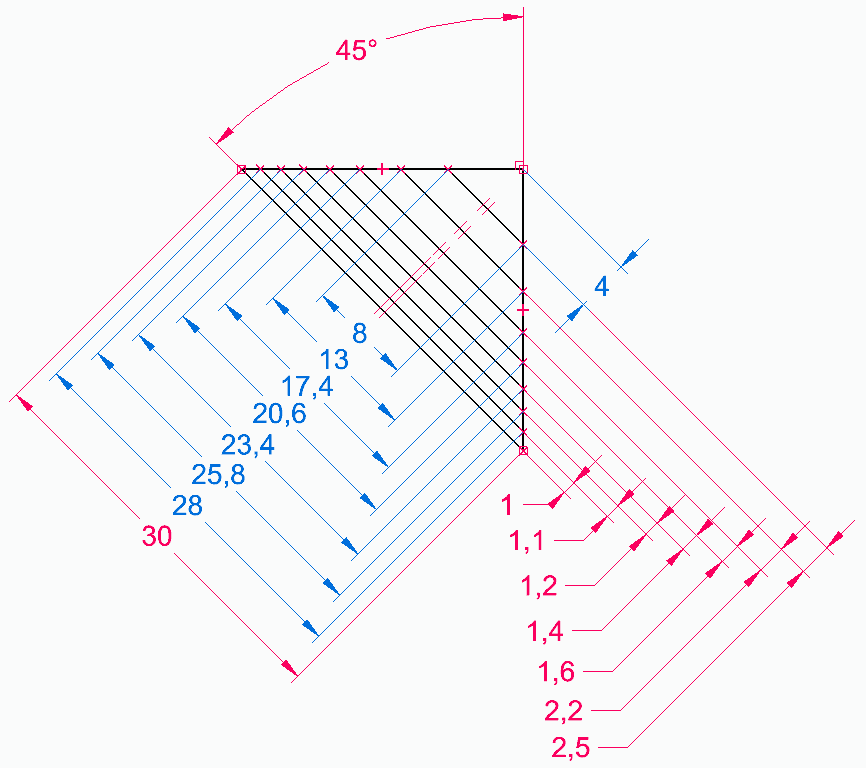

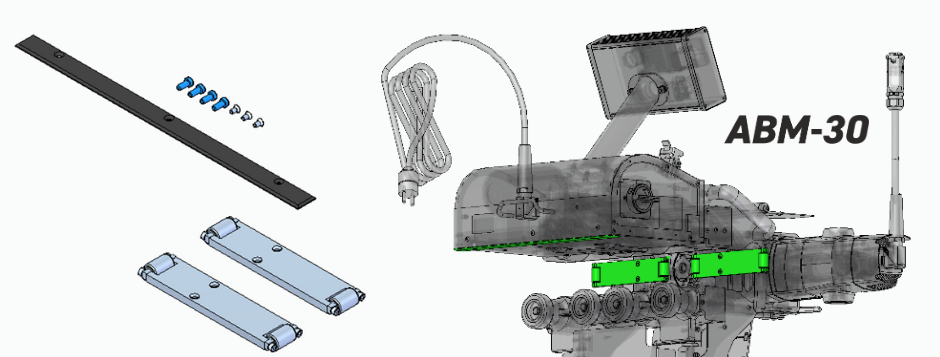

Beveling Stainless Steel with ABM-30

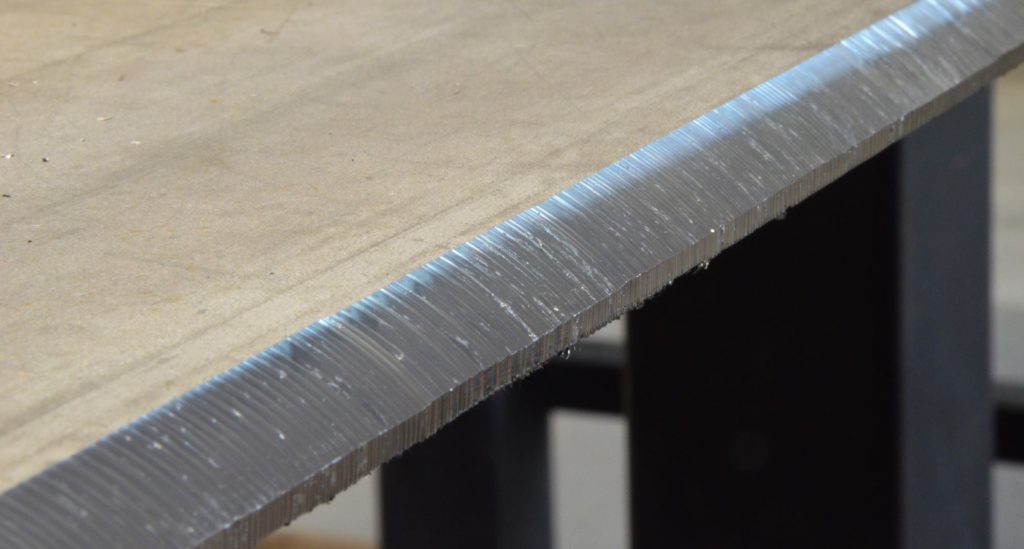

Auto-feed bevelling machine ABM-30 performs auto-feed beveling on steel plates on the top, face, and bottom edges. It is capable of creating maximum 30 mm wide bevel on stainless steel in 8 passes.

| ABM-30 – recommended steps for bevelling stainless steel | ||

| Pass no. | Max. In-depth progress of milling head [mm] | Bevel width obtained [mm] |

| 1st | 4.0 | 8.0 |

| 2nd | 2.5 | 13.0 |

| 3rd | 2.2 | 17.4 |

| 4th | 1.6 | 20.6 |

| 5th | 1.4 | 23.4 |

| 6th | 1.2 | 25,8 |

| 7th | 1.1 | 28.0 |

| 8th | 1.0 | 30.0 |

Gradually increase the head penetration into the material to widen the bevel progressively.

Dedicated Stainless Steel set for ABM-30:

• 2 roller guides made of AISI 304

• protective bumper and all mounting screws made of AISI 304

Product code: ZST-0690-16-00-00-0

Standard roller guides and a protective bumper can be replaced in a few simple steps, quickly and easily.

Why is it so crucial to use the correct machines when working with stainless steel?

Processing stainless steel can be challenging. Due to its hardness and lower thermal conductivity, it requires specialized machining tools and techniques, like the one that can be found in PROMOTECH’s offer. The machine with variable speed settings to accommodate different material properties and a powerful motor able to provide necessary torque and speed is essential to maintain precise and consistent bevelling.

Different grades and thicknesses of stainless steel may require different speeds for optimal cutting and stainless steel, compared to other metals, requires slower cutting speeds to prevent work hardening and reduce excessive tool wear. Machines with weak motors or inadequate cutting capabilities, however, will struggle, leading to inefficient cuts, tool wear, and even potential damage to the material itself.

To avoid contamination all parts and all tools intended for stainless steel should be used exclusively with these materials and kept separately from other materials. Cross contamination is a separate big topic in machining stainless steels. More about how to avoid stainless steel contamination you can read in our article >>