Bevelling: The Key to Strong and Reliable Welds

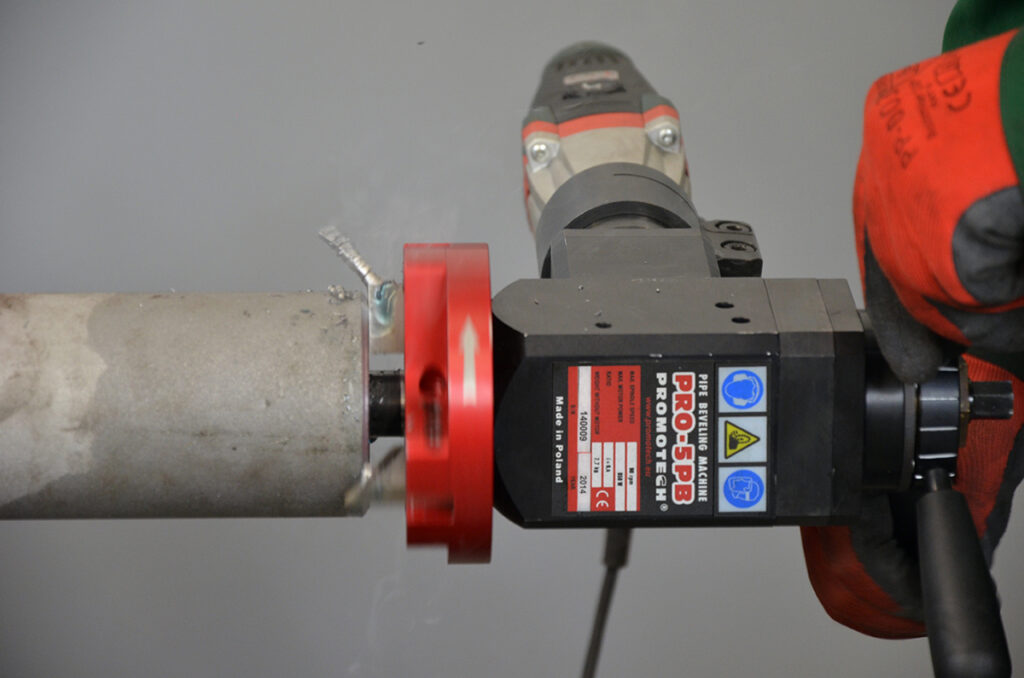

PRO-2 PB, PRO-5 PB, and PRO-10 PB bevellers are designed to ensure accurate pipe edge preparation, an important step for achieving durable, high-quality welds.

Minimizing errors and rework, saves both time and costs. It is particularly useful in automatic welding, incl. orbital welding, where precise pipe preparation enables a smooth process and eliminates potential issues.

PROMOTECH’s bevellers have proven themselves to be also particularly well-suited for membrane walls and boiler repairs in energy sources, renovations and maintenance.

How Does Pipe Bevelling Improve Weld Strength and Quality?

By increasing the contact surface for the weld, pipe bevelling improves even heat distribution, deep penetration and thus, results in a stronger weld. Eliminating irregularities and contaminants also minimizes the risk of future weld defects such as porosity or cracks. On the other hand, inaccurate bevels and poor fit-up can be the root cause of weld defects such as a lack of fusion/penetration, inclusions, blow through and excessive welding and labour costs.

Precision and Efficiency

Traditionally, achieving the ideal bevel on a workpiece was a labor-intensive and time-consuming task. However, now PROMOTECH’s PRO-2 PB, PRO-5 PB, and PRO-10 PB portable pipe bevelling machines, make this process quick and effortless. They are designed to mill pipes made of carbon and stainless steel, aluminium alloys, and copper-nickels and can be easily operated by one person. The speed is adjustable and depends on material, wall thickness and diameter, apart from pneumatic version.

Single-Operator Convenience

With their lightweight and ergonomic design, PROMOTECH’s pipe bevellers are perfect for single-operator use. Whether on-site or in a workshop, these machines deliver exceptional fit-up precision and high repeatability. Even in challenging positions and hard-to-reach areas.

Stable operation

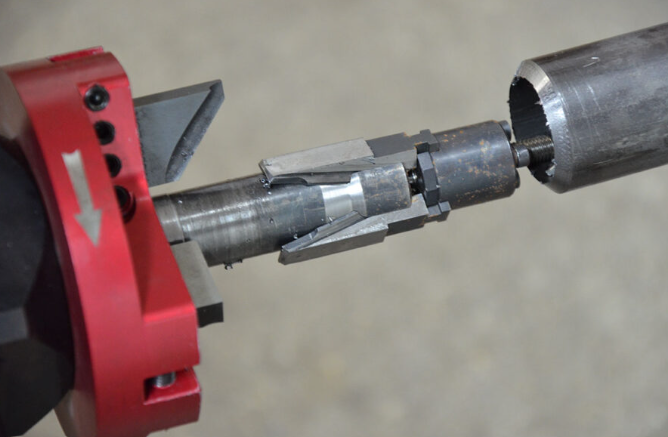

New generation of PROMOTECH’s portable pipe bevellers feature spindle disc with two tool bit holders. It allows more stable, less stress-sensitive operation of tool bits, further enhancing the tool’s efficiency. New machines still have all the remaining functionality of its predecessors, including the ability to operate three tool bits (with the use of optional accessories).

Self-Centering Expandable Mandrels

Maintaining consistent positioning is critical for uniform bevels. To achieve that PROMOTECH’s bevellers are clamped from inside the pipe with the use of self-centering expandable ID mounted mandrels. In result they ensure stable, precise alignment and consistent fit-up that repetitively lead to high quality results.

Thanks to the simpler setup, transitions from one pipe or tube to another across multiple operations are quicker, improving workflow and boosting productivity.

Facing and bevelling in a single step

Simultaneous external, internal bevelling, and facing of tubes or pipes with PROMOTECH portable bevellers is simple and allows for precise pipe preparation. This is particularly critical for heavy-wall pipes in weld preparation. By maintaining accurate alignment throughout the process, the risk of errors commonly associated with switching between separate operations is minimized.

Combining facing and bevelling is very efficient in repetitive tasks. It eliminates the need to reposition pipes or change tools, reducing overall preparation time significantly. The result is a superior fit-up, and enhanced weld penetration.

J-Bevelling for enhanced welding on thick-walled pipes

Designed for larger diameters, the PRO-5 PB and PRO-10 PB offer extended functionality with a J-bevelling option, enhancing welding efficiency on thick-walled pipes.

J-bevelling is commonly used as a surface preparation method for welding thick plates and pipes. It reduces the amount of filler material needed, thereby decreasing welding time. By beveling only one side of the joint, welders can achieve improved penetration and a stronger bond between the materials.

What benefits come from using J-bevels? Check our previous article >>

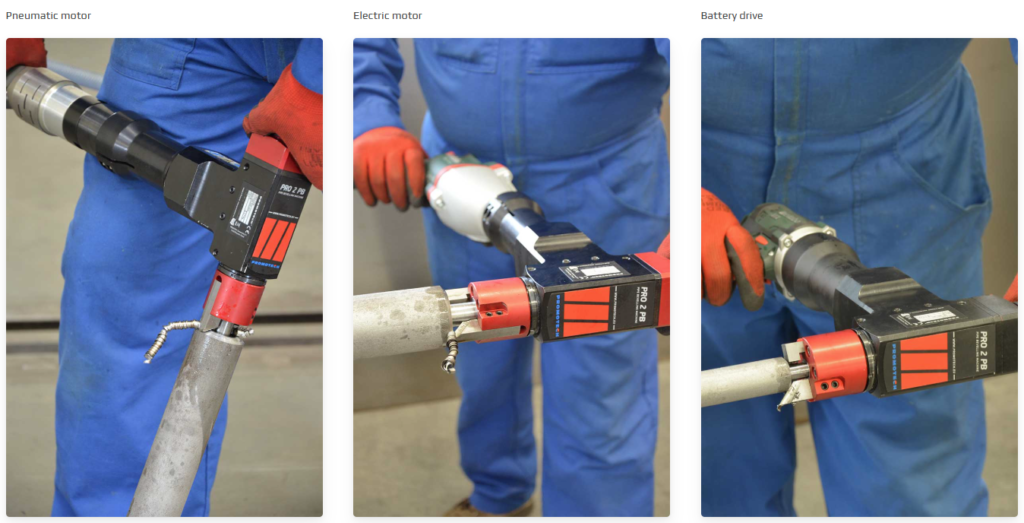

Powered by Pneumatic or Electric Motor, or CAS-Battery

Depending on users preferences, needs and onsite conditions, PROMOTECH PRO-2 PB, PRO-5 PB and PRO-10 PB offer three drive options to suit your application.

High-torque electric motor

Electric motors require less maintanance, but need a location with reliable electrical power which not always is available.

Pneumatic motor

Pneumatic motors provide higher torque and tend to be chosen for heavy-duty applications, especially if compressed air is already present at the location.

Flexible CAS-battery system

Not only are battery-powered tools highly beneficial, but often essential in workplaces that lack access to the electrical grid. They also increase safety, especially in confined spaces.

What does a multi-brand CAS battery system means? With CAS-battery powered tools, one can conveniently interchange batteries and chargers among them, regardless of the brand, as long as they are part of the CAS alliance. New charger and all LiHD battery packs (4.0, 5.5 and 10.0 Ah) are suitable for PRO-2 PB and PRO-5 PB pipe bevellers, and all CAS battery-powered machines.

For extended operations, charge a spare battery simultaneously or keep a sufficient number of fully charged batteries on hand. This strategy guarantees uninterrupted and smooth operation.

More information about CAS battery system can be found in the previous article >>

Regardless of the chosen power source, portable pipe beveling machine provides the same range of functionalities.

Versatile for Diverse Industries

PROMOTECH PRO-2 PB, PRO-5 PB and PRO-10 PB bevellers have proven themselves to be particularly well-suited for membrane walls and boiler repairs in energy sources, renovations and repairs.

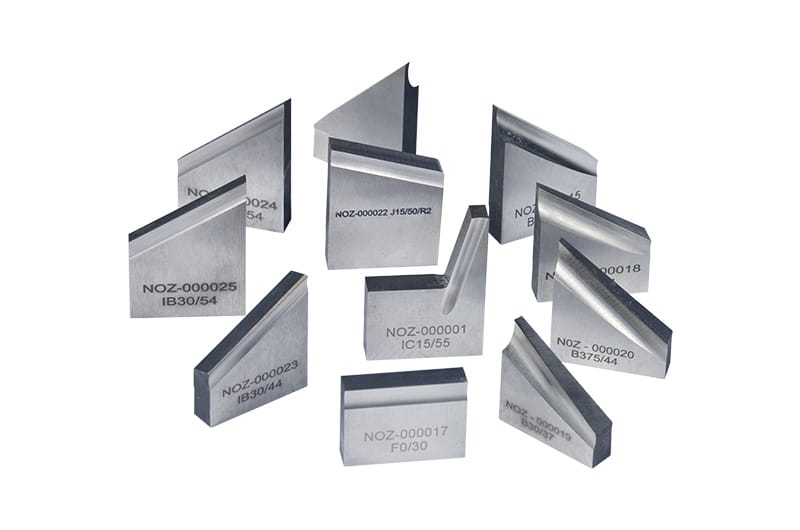

Available with a variety of standard and custom-made tool bits, pipe bevellers are adaptable to various tasks and materials. From the energy sector and shipbuilding, to steel construction and beverage manufacturing, pipe bevelling machines are tailored to meet the demands of various industries.

Customers also benefit from a two-year warranty, post-warranty service, and guaranteed availability of spare parts.

New generation of portable pipe bevellers

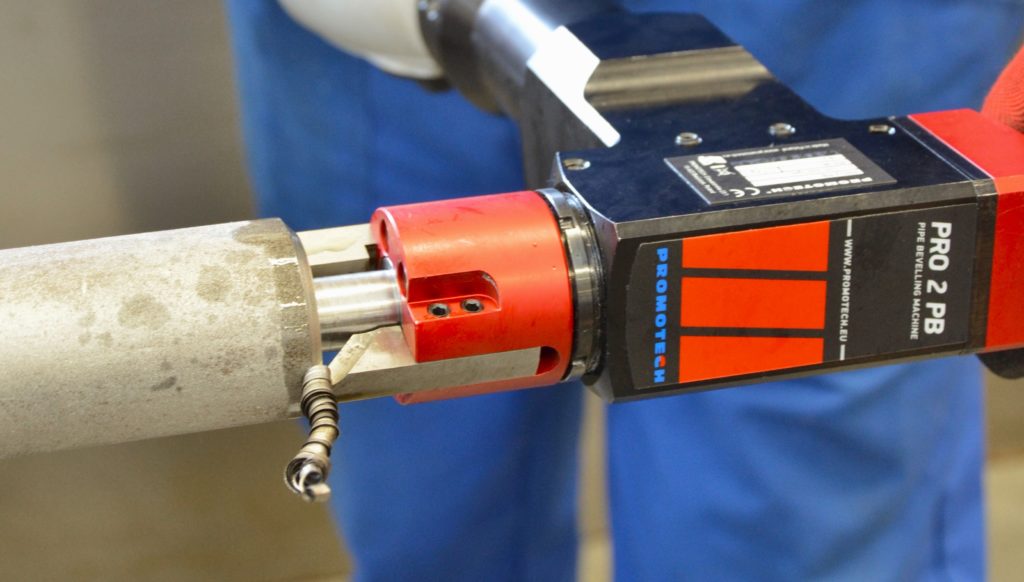

New generation of PRO-2 PB portable pipe beveller uses a new, more effective method of mounting the mandrel inside the pipe or tubing. Previously used set of jaws, jaw blocks and springs is now replaced with expandable sleeves and spreaders which make the preparation of PRO-2 PB to work faster and easier. After finishing the task, sleeve returns to its starting point diameter.

Additionally, PRO-2 PB incorporates overload systems, including wet multi-disk friction clutch to prevent gear damage if the tool gets stuck.

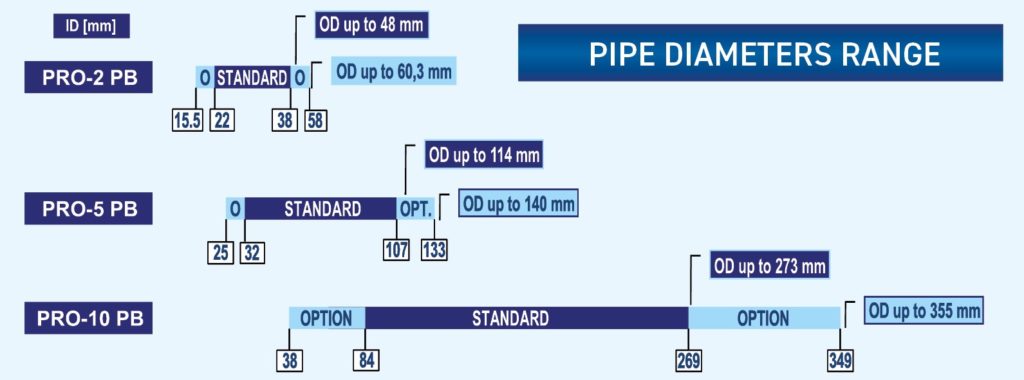

𝗣𝗥𝗢-𝟮 𝗣𝗕

ID 19.5 – 38 mm, ID 15.5 – 22 mm /option/, ID 38 – 58 mm /option/

Max OD bevel width up to 48 mm, OPTION – 60.3 mm

The smallest in this range – PRO-2 PB can face and bevel pipes from inner diameters (ID) of 19.5 mm to outer diameters (OD) of 48 mm. Small pipes from ID 15.5 mm up to OD 29 mm can be bevelled with optional small mandrel set. An optional extension set allows you to bevel pipes from inner diameters of 38 mm to outer diameters of 60.3 mm.

Its exceptionally narrow housing (only 48 mm wide) makes it perfectly suited to space-restricted areas such as boiler water walls.

ID 32-107 mm, ID 25-32 mm /option/, ID 107-133 mm /option/

Max OD bevel width 114 mm, option – 140 mm

Depending on the tool bits, PRO-5 PB can perform external bevelling, internal bevelling, J-bevelling, internal calibration, and facing pipes from inside diameters of 32 mm to outer diameters of 114 mm or up to 140 mm as option. An optional small expanding mandrel allows machining pipes with inner diameters from 25 mm to 32 mm.

𝗣𝗥𝗢-𝟭𝟬 𝗣𝗕

ID 84-269 mm, 38-84 mm /option/, 270-349 mm /option/

Max OD bevel width 273 mm, option – 355 mm

Depending on the tool bits, the machine allows external and internal beveling, J-bevelling, internal calibration, and facing pipes of inner diameters of 84-269 mm.

An optional small expanding mandrel allows you to bevel pipes ID from 38 mm to 86 mm. An extension set allows you to bevel pipes of diameters from 192 mm to 355mm. Attachments allow you to face pipe flanges of diameters from 90 to 508 mm and to bevel oval pipes from 126 mm to 296 mm.

PROMOTECH’s PRO-2 PB, PRO-5 PB, and PRO-10 PB bevellers are expertly designed to ensure precise and efficient pipe edge preparation, a critical step for achieving durable, high-quality welds. With their user-friendly design and one-man operation, these machines excel in various industrial applications, including automated welding processes like orbital welding.