Discover OSC-8 PRO: Pendulum Oscillator with LED Display

Whether you’re working in pipeline construction, shipbuilding, or heavy fabrication, the OSC-8 PRO Pendulum Oscillator is designed to optimize welding quality, increase productivity, and improve control over the welding process. Now we are introducing OSC-8 PRO – a new generation of the OSC-8 pendulum oscillator that will replace the previous model.

Why Choose a Pendulum Oscillator?

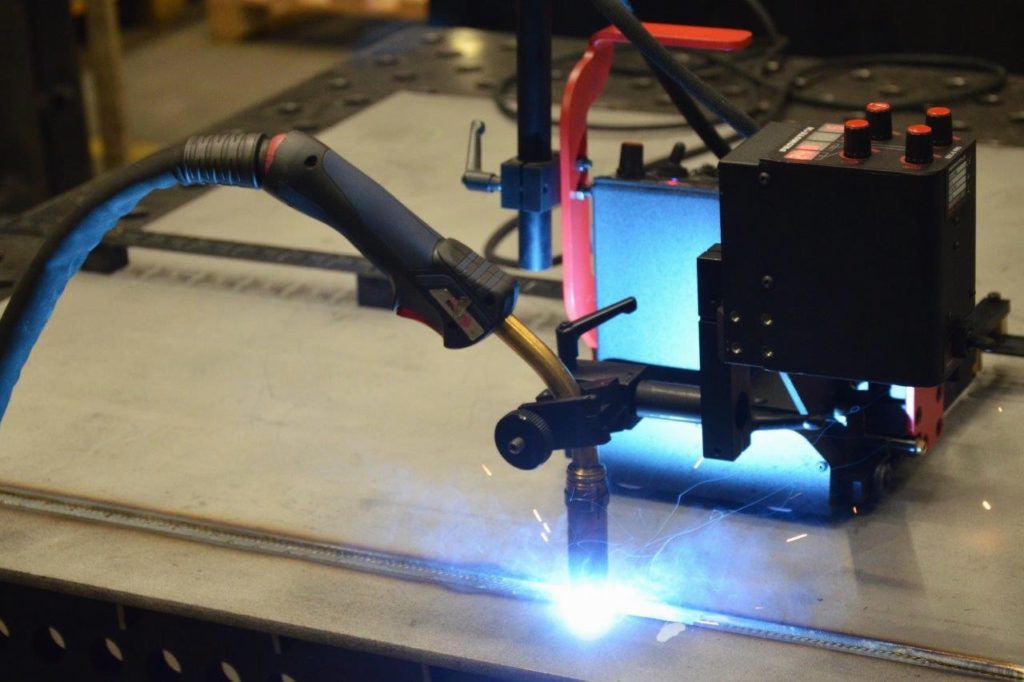

The OSC-8 PRO retains all the features that made the original OSC-8 a popular choice among welders. It is designed to oscillate MIG/MAG torches with a diameter of 16–22 mm (5/8–7/8″). The oscillator is installed onto a 22 mm (7/8″) diameter rod and connected to a welding device.

The oscillator seamlessly adapts to various weld joint geometries, producing triangle or trapezoid oscillation paths. OSC-8 PRO ensures optimal material deposition and better fusion between the base metal and the weld metal, particularly in thicker sections. When welding wide grooves or gaps, oscillation enables wider weld beads with a weaving pattern, covering a larger area more effectively. Multiple layers ensure robust and high-strength joints.

Using PROMOTECH’s OSC-8 PRO weave welding solution significantly reduces spatter and material waste, eliminating the need for rework and minimizing post-weld clean up.

Additionally, automating the oscillation process allows welders to focus on other aspects of the welding job. This reduces fatigue and risk of human errors, improves efficiency, and speeds up production process.

What’s New in the OSC-8 PRO?

The major upgrade comes in the form of an integrated LED display. It provides a user-friendly interface for setting and monitoring key welding parameters. Control panel with four knobs ensures precise adjustment of the parameters.

This digital LED display allows for real-time monitoring of:

- Oscillation width – for even distribution of weld material across the joint.

- Oscillation speed – optimal for the given application

- Right and left dwell times – to control the duration the torch remains at the ends of each oscillation cycle

The precise control of oscillation parameters ensures better penetration and overall weld integrity.

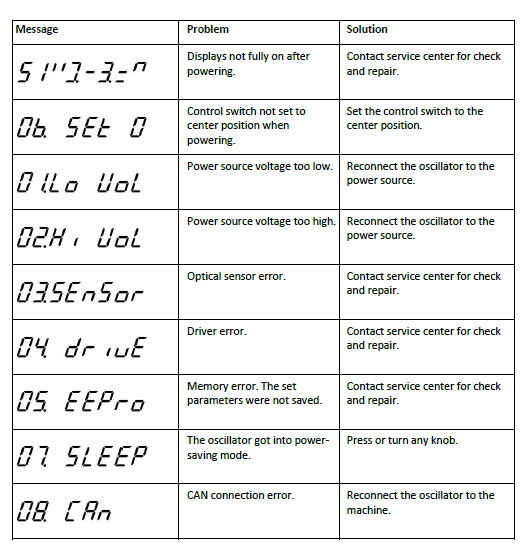

The display also provides diagnostic and safety information, ensuring smooth operation and easy troubleshooting.

If you’re already using the OSC-8, upgrading to the OSC-8 PRO gives you the advantage of precise digital control and improved ease of use, while retaining all the reliability of the previous OSC-8 model.

Multiple configurations

The compact OSC-8 PRO is designed for easy installation and quick deployment in different work environments. Its lightweight construction makes it ideal for fieldwork and confined spaces. It can be used in multiple configurations:

✅ As a stand-alone unit for independent operation

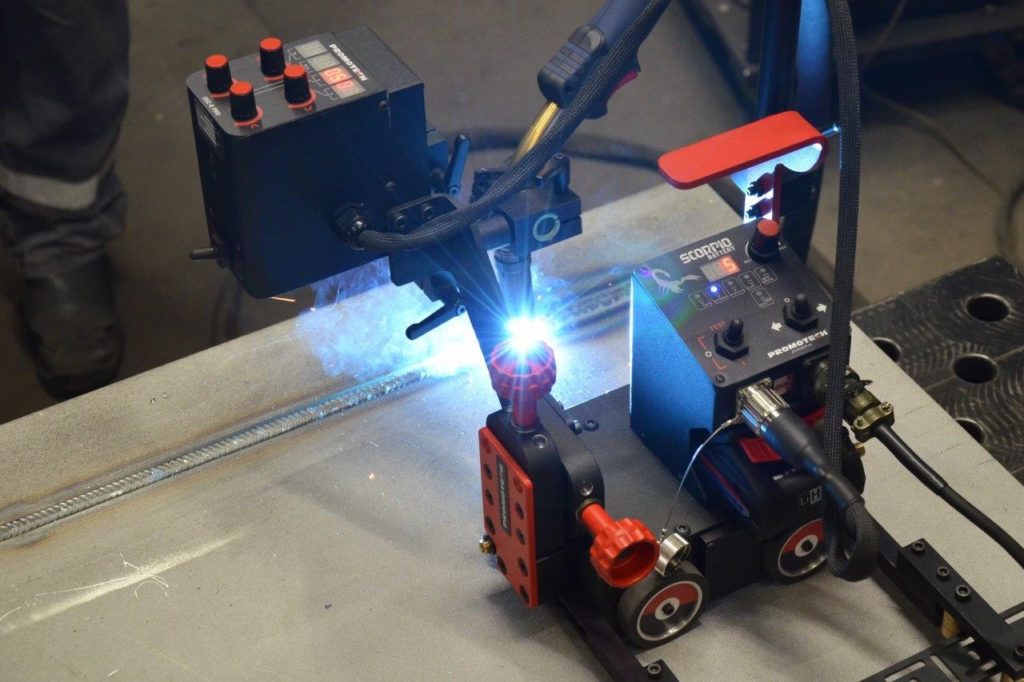

✅ With track-mounted and trackless welding tractors, such as PROMOTECH GECKO, GECKO Battery RAIL BULL, RAIL TUG, RAIL TITAN, RAIL TITAN 2, SCORPIO Battery

✅ Mounted on column & boom or gantry systems for heavy fabrication applications, such as PROMOTECH WA Compact, Mini Column & Boom System

✅ With optional freestanding support and positioners for cylindrical and rotating workpieces, such as PROMOTECH PRO-WP 150, PRO-WP 300, PRO-WP 300P, PRO-WP 750P.

Whether it’s long seam and fillet welds in pipeline and bridge construction, curved surfaces in vessel or tank fabrication, or high-volume projects in heavy industry, by minimizing defects like undercutting and lack of fusion, PROMOTECH’s weave welding solution OSC-8 PRO is a perfect fit for various industries.