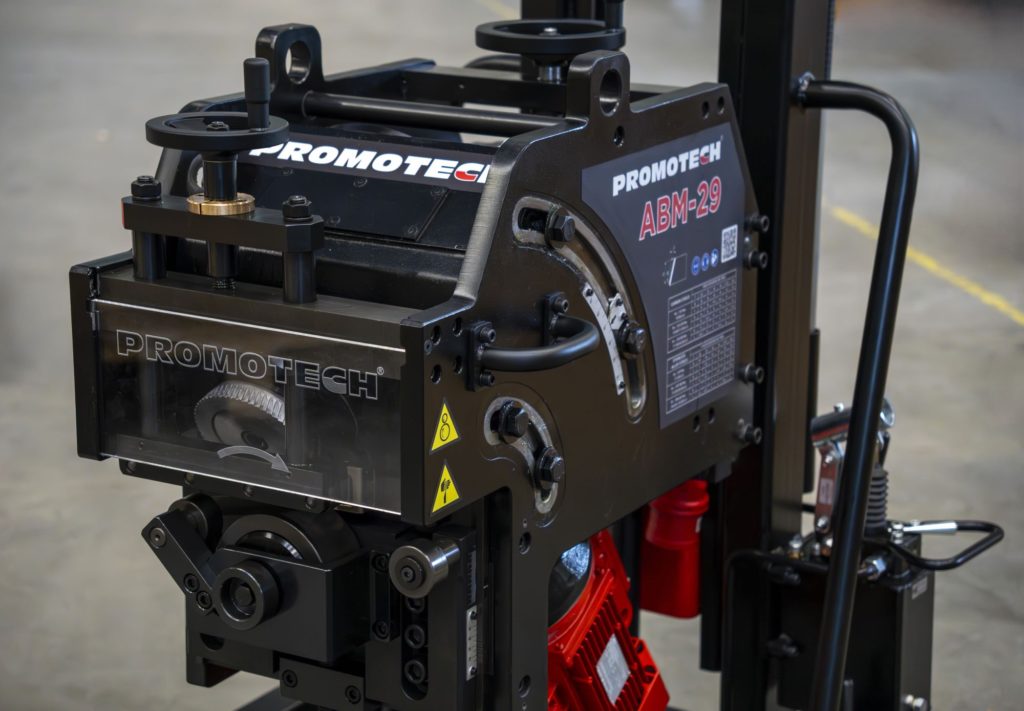

High efficiency and up to 20 mm in a single pass. ABM-29 industrial beveller.

Responding to the needs of the metalworking industry, we introduce the PROMOTECH ABM-29 industrial beveller for double-sided plate machining. This new addition perfectly complements our popular and reliable, but smaller ABM-14 beveller. Now, with PROMOTECH ABM-29 one can comfortably bevel up to 20 mm in width in a single pass! Be prepared for the extraordinary.

Variable Bevel Width: Up To 20mm In One Pass

You can find machines that, like the ABM-29, offer bevelling to a width of 29mm at a 45-degree angle, but it’s the ABM-29 that allows you to achieve a 20mm bevel in just one pass! Depending on the material a few more runs are needed to get a maximum bevel width of 29 mm.

PROMOTECH ABM-29 bevels with a speed 1,7m per minute for 50 Hz and 1,9m/min for 60 Hz. Set the milling depth and bevel height and receive consistent quality and remarkable final result. Every time.

Unleash the power of fast double-sided bevelling!

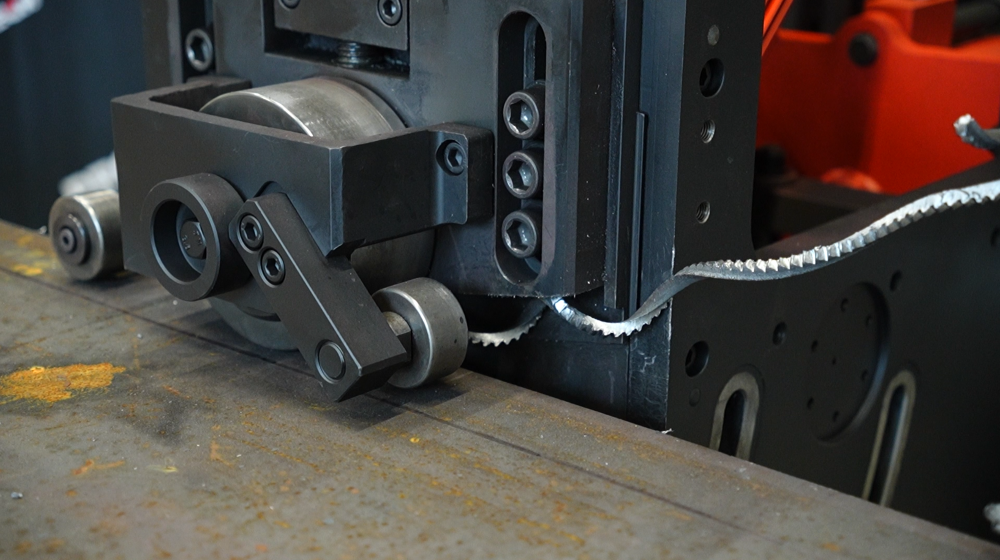

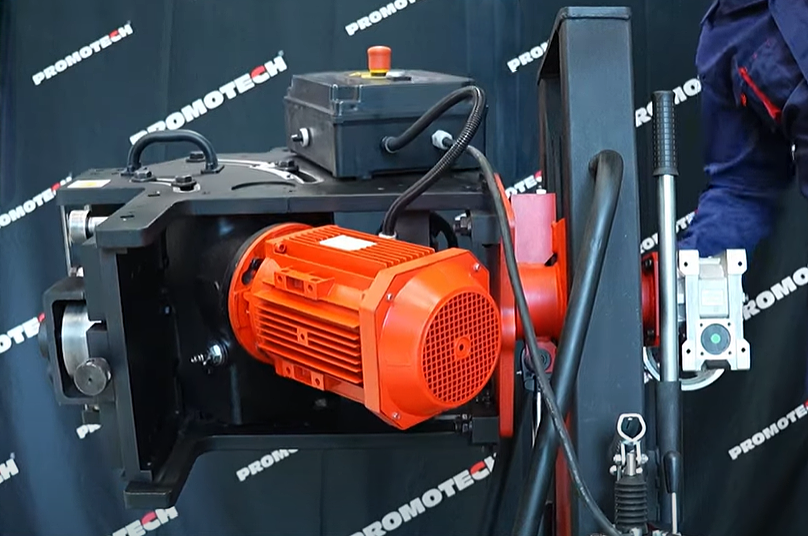

New machine PROMOTECH ABM-29 offers advanced capabilities for double-sided plate machining using a shearing cutter. The powerful electric motor ensures smooth performance and efficient operation. With automatic feed, ABM-29 travels smoothly along the edges of the sheet plate, enabling consistent and precise bevelling on both top and bottom edges. Works perfectly well in the industrial environment, also with long and heavy plates of thickness up to 50mm.

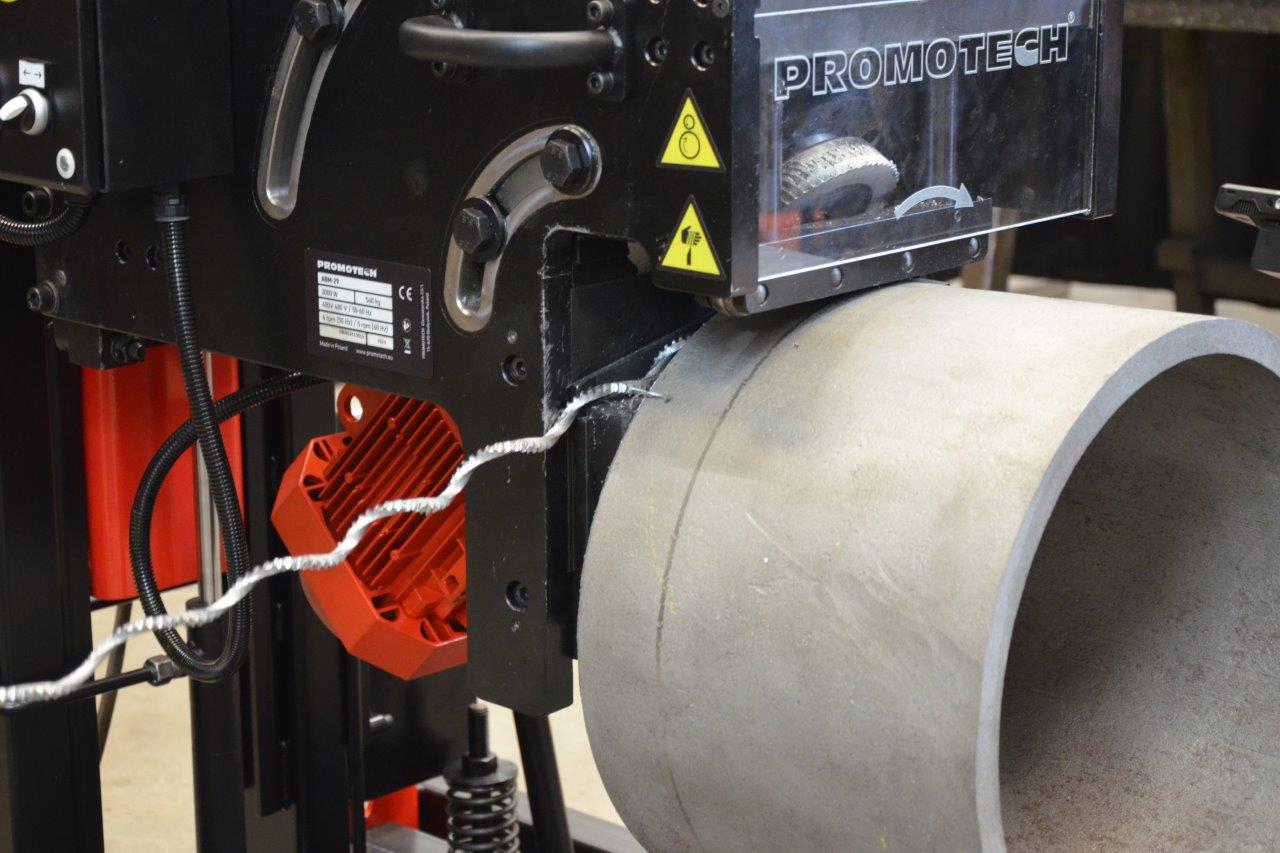

While machining smaller workpieces or pipes (diameter min. 150 mm) stationary operation of ABM-29 is also possible.

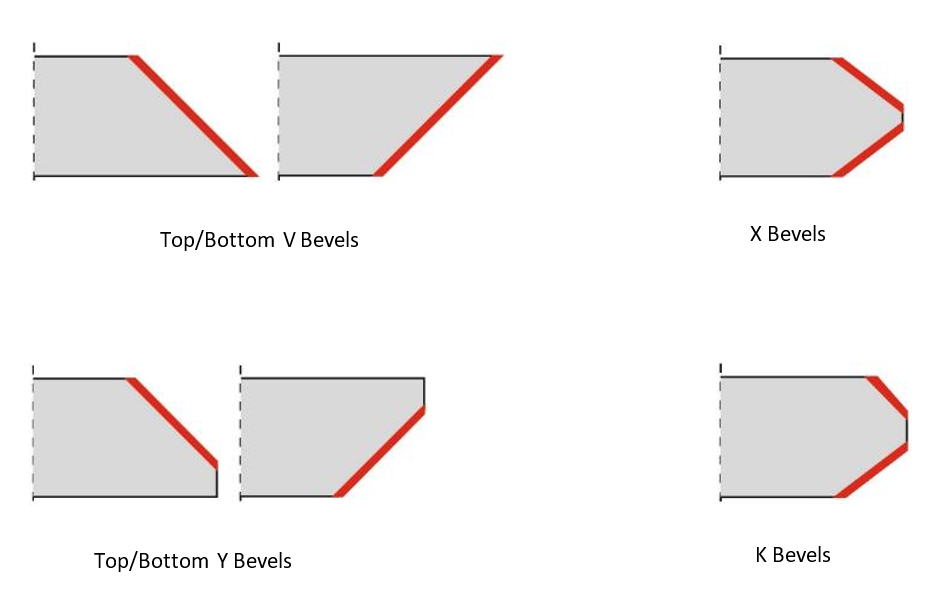

The heavy-duty ABM-29 enables the production of double-sided bevels between 20 and 45 degrees on a variety of steel grades, including stainless steel and other hard machining materials. It bevels large sheets efficiently and with minimal distortion. All that without the need to flip the plate. Perfect for professionals who seek a robust machine they can rely on. With its durable construction and precise engineering, this beveller performs its tasks effectively and efficiently.

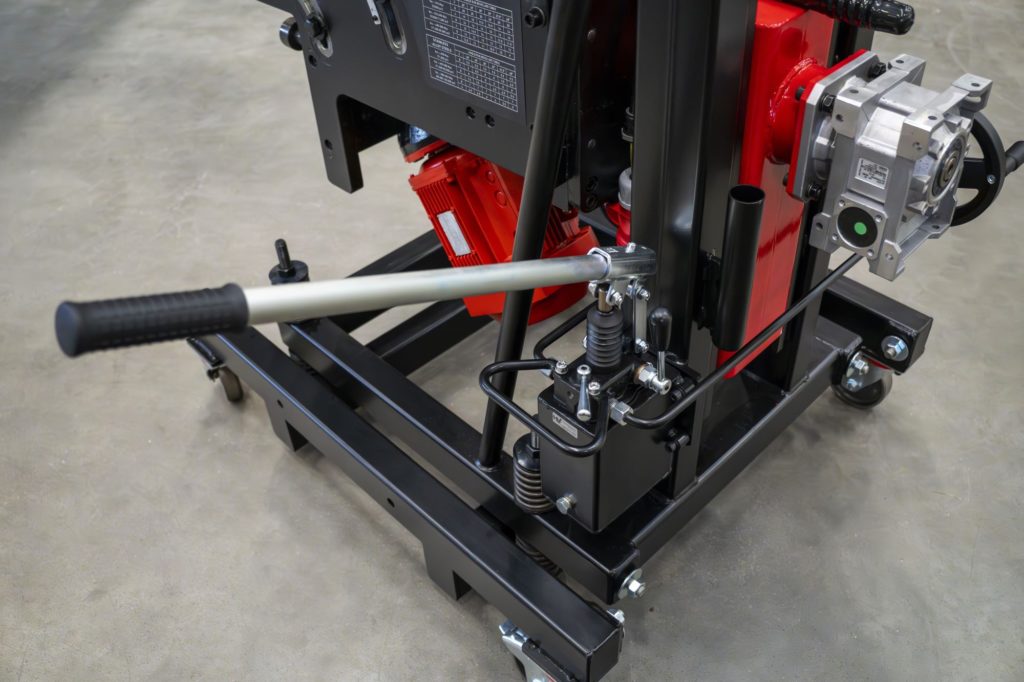

The Built-in Ergonomic Trolley for Your Comfort

The built-in trolley that comes with ABM-29 is a well-thought-out, purposeful design aimed at ensuring convenience and safety of use.

The trolley enables effortless 180-degree rotation of the machine for top and bottom beveling without the need to flip the plate. It also features hydraulic height adjustment, allowing the machine to be positioned between 685 and 1000 mm relative to the plate. Once positioned, a mechanical lock securely holds the machine in place, either at the top or bottom, enhancing both safety and convenience.

Additionally, to compensate for floor irregularities and plate imperfections, the chassis of the trolley is fitted with springs, making it a comfortable and practical tool for transport and storage.

Easy Adjustment and Operation

Stepless adjustment of the bevel angle allows precise effects. By turning a two-spoked handwheel and loosening 6 screws, you can set the angle between 20 and 45 degrees. Then, the built-in trolley allows for steady height positioning. A reversible spindle prevents tool jamming, enhancing the machine’s durability and reliability.

Possible Types of Bevels

PROMOTECH ABM-29 beveller main features & benefits:

- Moves automatically along the edge of the plate in the upper and inverted positions

- Enables up to 20 mm bevel width in one pass and max. 29 mm in several runs

- Stepless adjustment of the bevel angle between 20 and 45 degrees

- Continuous milling depth / bevel height adjustment for full control

- Powerful electric motor 3000 W

- Single shearing cutter for machining a variety of steel grades incl. stainless/alloyed steel

- Built-in trolley for comfortable operation and easy height adjustments

- Stationary operation for small workpieces or pipes (ID > 150 mm)

- Quiet operation

- Reversible spindle against stuck milling tool

ABM-29 Technical Specification

| Specification | Details |

|---|---|

| Voltage | 3×400 V / 3×480 V + PE, 50-60 Hz / 3×240 50-60 Hz |

| Power | 3000 W |

| Spindle speed | 1445 rpm (4 rpm for 50 Hz, 5 rpm for 60 Hz) |

| Bevel angle (β, Fig. 1) | 20°-45° |

| Maximum bevel width (b, Fig. 1) | 29 mm |

| Maximum bevel in one single run | 20 mm |

| Maximum height of cut (h, Fig. 1) | 14.5 mm |

| Minimum plate thickness | 10 mm |

| Maximum plate thickness | 40 mm (50 mm*) |

| Minimum plate width | 80 mm |

| Bevel length per minute | 1.7 m/min for 50 Hz, 1.9 m/min for 60 Hz |

| Minimum pipe ID | 150 mm |

| Weight | 580 kg |

The ABM-29 Auto-feed Double-Sided Beveller is a combination of efficiency, versatility, and ergonomic design. Efficient and quiet, ideal for precise bevels on a variety of materials.