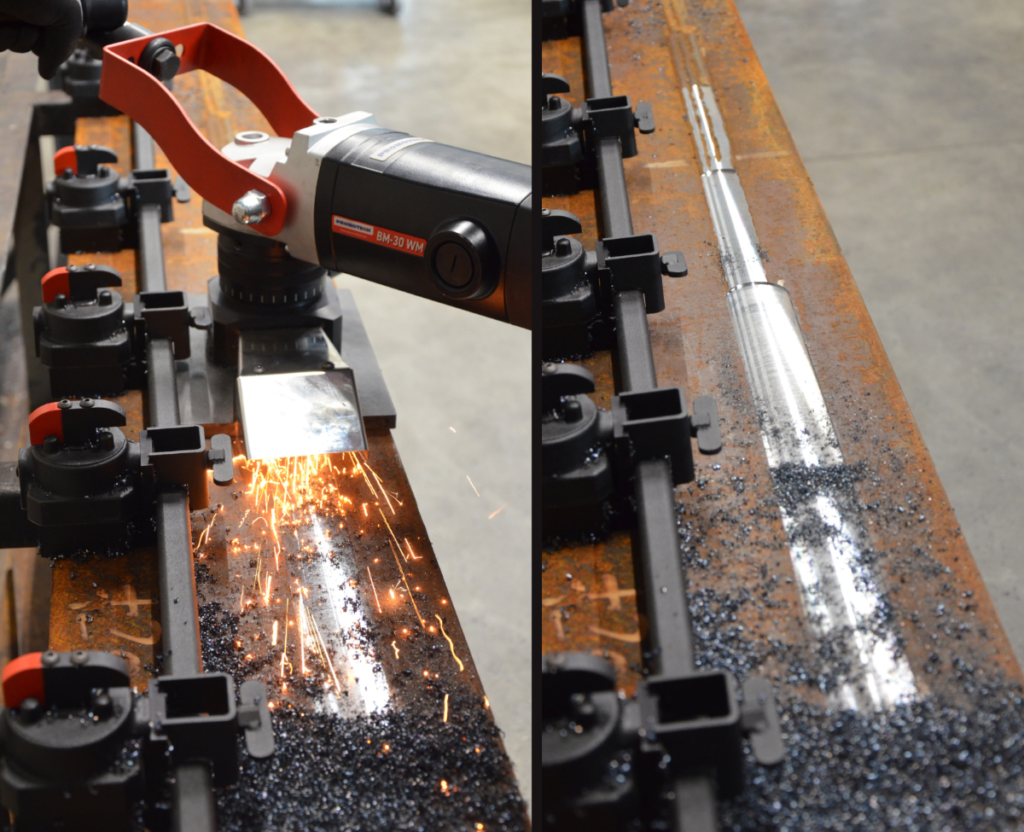

Experience seamless operations with a user friendly weld milling machine PROMOTECH BM-30 WM which is capable of milling a weld seam down to a level of continuous surface with the rest of the parent metal. It is designed specifically for the removal of excess weld seams up to 11 mm high and 30 mm wide. It also enables precise undercutting to a depth of up to 1.5 mm. Producing smooth and uniform surfaces with precision, overall efficiency and safety, BM-30 WM proves to be a modern solution that ensures efficient workflow and high-quality results.

By removing irregular welds seams, adhesion and quality of the subsequent processes, such as painting, coating, or any other further processing is distinctly improved.

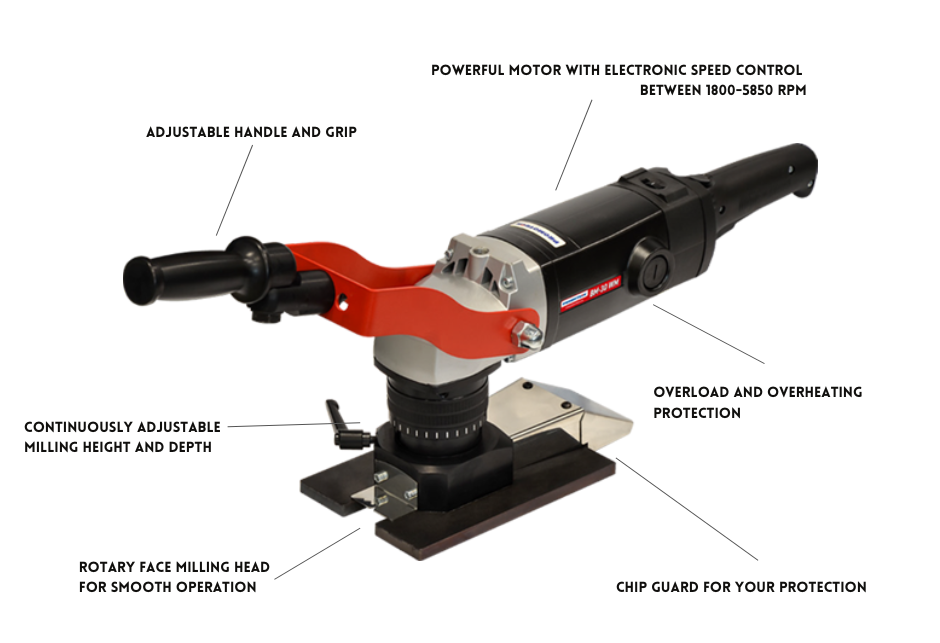

Powerful electric motor

A powerful 2200W motor is fitted with Electronic Speed Control which by regulating and adjusting the speed between 1800–5850 rpm, optimizes cutting conditions.

Milling Head Design

The beveller BM-30 WM is equipped with a rotary face milling head fitted with 5 pieces of 2-sided indexable cutting inserts. It ensures less milling resistance and exceptional efficiency without creating any heat-affected zones or distortion of the workpiece.

Operator Friendly

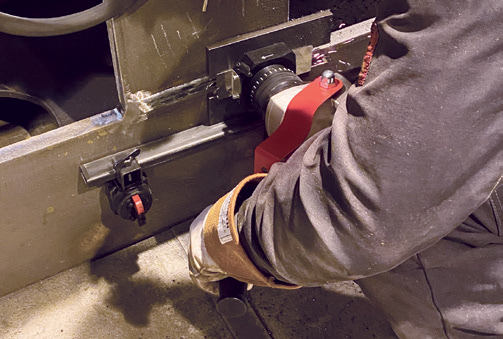

Easy to set up, use, and adjust. Weld milling machine BM-30 WM provides convenient access to the milling head and cutting inserts. Meanwhile, an ergonomic handle and grip with continuous milling height/depth adjustment, ensure comfort and safety during use.

Safety First

One of the important features that contribute to general safety is the chip guard. It is positioned around the milling head to protect the operator from flying debris or chips that might be generated during the milling process.

Guidance System

PROMOTECH BM-30 WM is equipped with a guide rail (500 mm long) with a magnetic clamping system that is joinable for unlimited run length. It ensures a constant, correct position of the machine against the workpiece.