Avoid steel contamination with stainless steel BM-25S beveller

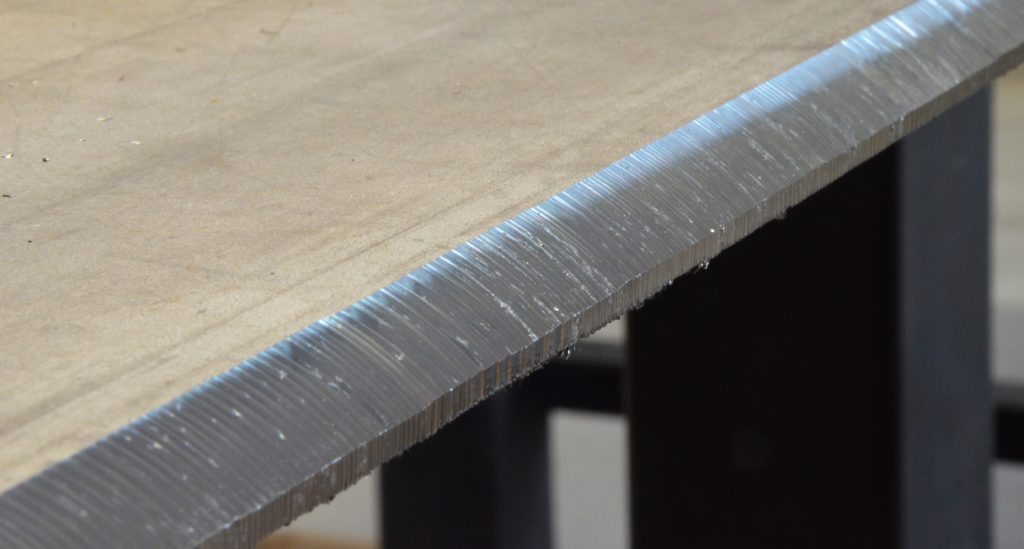

The new BM-25S beveller takes the renowned BM-25 model to new heights, extending its functionality to include machining of stainless steel with no need for extra accessories. BM-25S is equipped with stainless steel guide rollers, which not only make bevelling easier, but also protect against contamination.

Why to choose Stainless Steel?

Carbon steel and stainless steel are two of the most popular steel alloys. Carbon steel is composed mainly of iron and carbon. The carbon content varies depending on the type, ranging from 0.05% in low or mild carbon steel to up to 3% in ultra-high carbon steel. Stainless steel, on the other hand, primarily consists of chromium, nickel, and molybdenum, with at least 10.5% chromium by weight. The presence of chromium is crucial to provide corrosion resistance. What makes stainless steel premium material?

Superior Strength & Hardness

Compared to low-carbon steel, stainless steel provides a significant upgrade in strength and hardness.

Resilient

It can withstand temperatures up to 300°C and high humidity, without losing its properties or structural integrity. Stainless steel is also resistant to a wide range of chemicals and acids, making it useful in chemical processing industries.

Exceptional Corrosion Resistance

It does not degrade easily when exposed to moisture, chemicals, and other environmental factors and offers unparalleled protection against corrosion and rust.

Long-lasting

This material does not lose its quality over time. Stainless steel has high tensile strength and retains its mechanical properties, integrity, and performance over time. Structures and products made from stainless steel remain reliable throughout their lifespan.

Easy to Clean

Its smooth, sheen-like, and non-porous surface makes it easy to clean and sanitize. Compared to other materials, it requires minimal maintenance.

The key advantage of stainless steel lies in its outstanding resistance to corrosion and rust. It remains intact and functional for a long time, making it an ideal choice for applications requiring pristine, corrosion-free surfaces, such as laboratories, food processing, pharmaceuticals, and chemical industries.

Still, there are several ways that stainless steel can become contaminated, the three major causes of contamination being carbon, chloride or mild steel.

Preventing Steel Contamination

Why is it so crucial to use the correct machines when working with stainless steel?

Processing stainless steel can be challenging. Due to its hardness and lower thermal conductivity, it requires specialized machining tools and techniques. Most importantly, to maintain its qualities, it is crucial to avoid steel contamination. Any mild steel or iron item that comes into direct contact with stainless steel can induce galvanic corrosion, accelerating rust formation. This can significantly reduce its lifespan, disrupt intended functionalities, and compromise the final product’s quality and durability.

That’s why all tools intended for stainless steel should be used exclusively with that material and kept separate from others. To avoid contamination, consider covering them with plastic sheeting or wrapping, especially if there is a risk of iron filings from grinding or cutting carbon steel spreading and landing on the stainless steel.

A professional steel fabricator knows how important it is to avoid stainless steel contamination at every stage, from storage and handling to fabrication and throughout its service life.

The first step to prevent steel contamination, however, is to choose the right machine, designed to handle stainless steel, such as the portable heavy-duty BM-25S beveller.

How to choose a proper beveller for stainless steel machining

In the process of selecting a proper beveller, take these aspects into particular consideration:

No Contamination

To ensure optimal performance and prevent steel contamination, all beveller’s components have to be resistant to corrosion. All elements that stay in touch with stainless steel should be made from non-ferrous materials.

Sufficient Power

Remember that stainless steel is a tough and hard material that requires a machine with sufficient power. A powerful motor able to provide necessary torque and speed is necessary to maintain precise and consistent bevelling.

Variable Speed

Different grades and thicknesses of stainless steel may require different speeds for optimal cutting. In general, compared to other metals, stainless steel requires slower cutting speeds to prevent work hardening and reduce excessive tool wear.

Gradually increase the head penetration into the material to enlarge bevel width step-by-step. The best choice is a machine with variable speed settings to accommodate different material properties, manage heat, extend tool life, and achieve high-quality finishes.

Proper Cutting Tools

Employ inserts or tool geometries designed for stainless steel machining. They need to be made from high-quality materials that can withstand stainless steel’s hardness without excessive wear. For that reason, it is also recommended to remove a similar volume of stainless steel in each successive step, ensuring your inserts last longer. Use sharp tools and avoid excessive pressure on the cutting edge to minimize work hardening.

Heat Build-up Control

Effective cooling and lubrication systems are essential to prevent heat build-up and tool wear during machining. Use a coolant or lubricant to reduce heat and prolong tool life.

By considering these factors, you can select a beveller that is well-suited for stainless steel machining while preventing steel contamination, thus ensuring high-quality and reliable results.

How BM-25s is prepared to prevent stainless steel contamination?

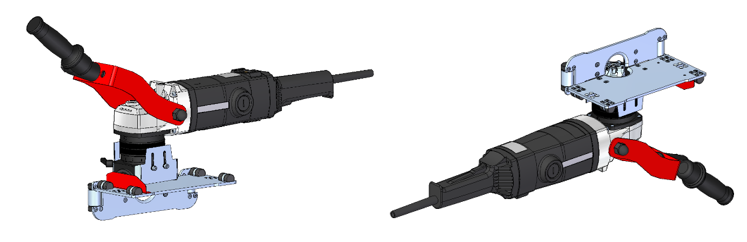

Bevelling stainless steel with other PROMOTECH machines, such as BM-25 beveller or auto feed trackless ABM-30 beveller is possible, but requires the use of special accessories. New heavy-duty beveller BM-25S, on the other hand, doesn’t require any extra accessories. It is specifically designed for stainless steel.

No Contamination

The BM-25S beveller is equipped with stainless steel roller guide, which not only makes bevelling easier, but also protects against contamination.

Power

The BM-25S beveller, with its robust 2200 W electric motor and motor overload module, is well-suited for efficient bevelling without undue strain on the tool. If an overload occurs, the motor shuts off. This may occur when the bevel width is too large for the hardness of such material or when the cutting inserts are dull. Therefore, to prevent overload, machine hard materials in multiple passes and replace the inserts before they become dull.

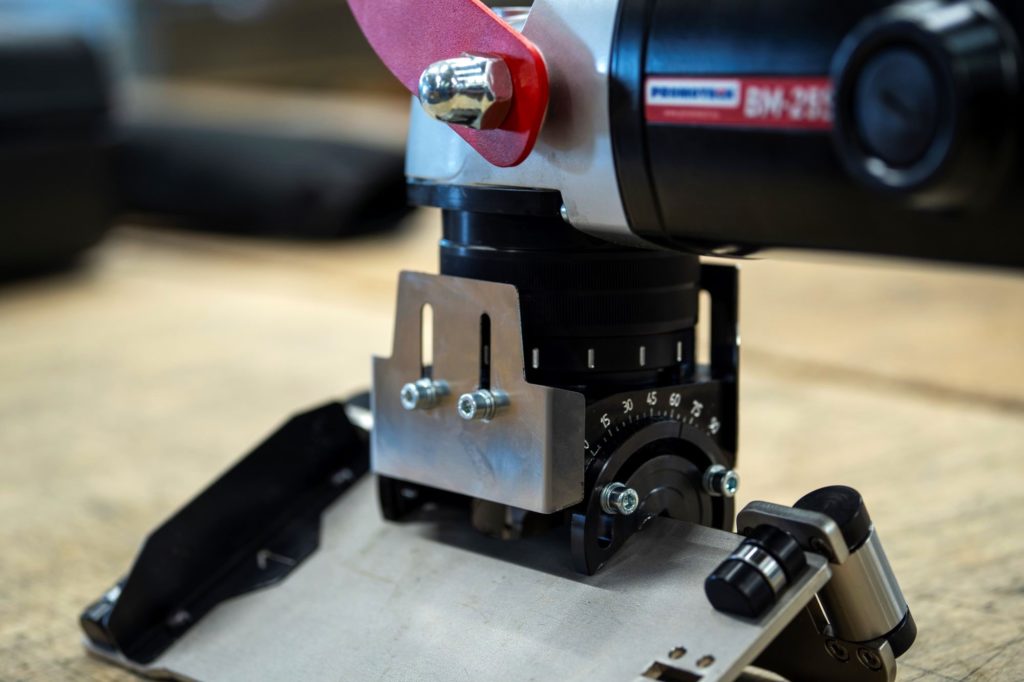

Speed

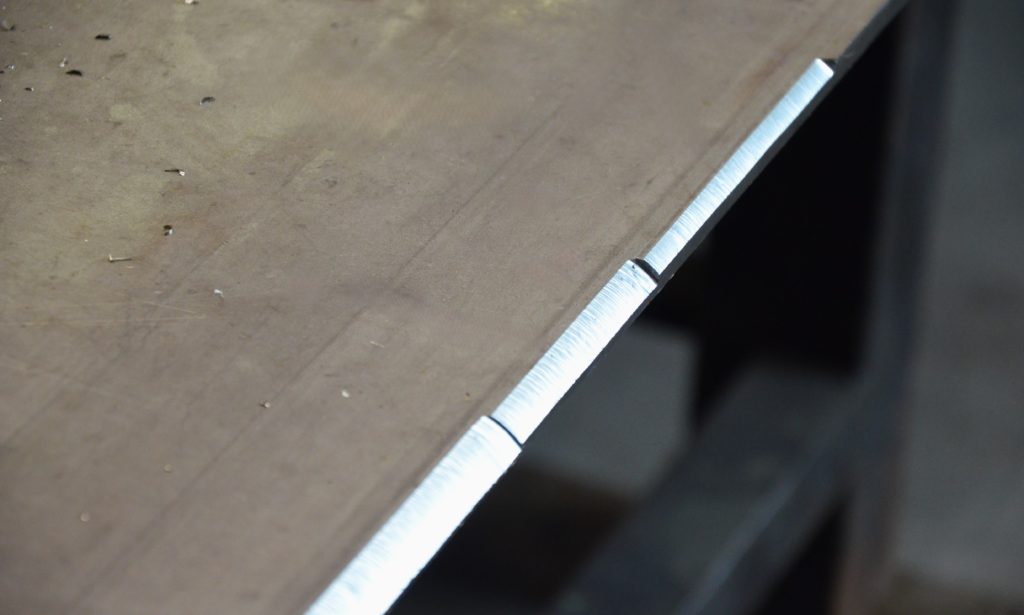

BM-25S allows milling of straight edges with a bevel width up to 25 mm and the variable spindle speed makes it easy to optimize cutting conditions. New beveller is equipped with an electronic system that allows the operator to adjust the rotational speed of the bevelling head within a range of 1800 to 5850 rpm.

Lower speeds are often used for initial cuts, precise work, or when working with stainless steel. Being able to adjust the speed allows the operator to manage the heat generated during bevelling, reducing the risk of work hardening or warping the material. Higher speeds can be used for faster material removal, more aggressive cutting, and when working with materials that can handle higher heat and cutting forces.

By adjusting the speed to optimal levels, the stress on the beveller can be minimized, preserving its sharpness and effectiveness.

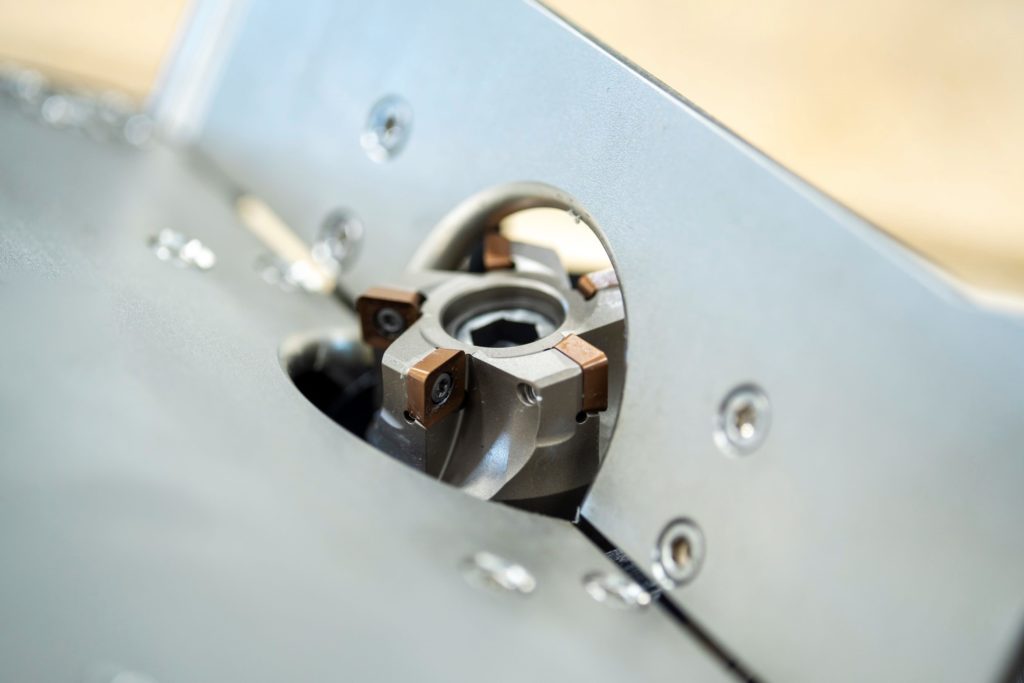

Proper Cutting Tools

BM-25s allows for beveling at the angle from 0° to 90° and with the maximum bevel width of 25 mm, however, the recommended range is from 15° to 75°. Milling head is equipped with 5 pieces of 4-sided indexable cutting inserts, making the bevelling process more efficient and effective. Positive rake angles and sharp cutting edges help in reducing cutting forces and improving chip evacuation.

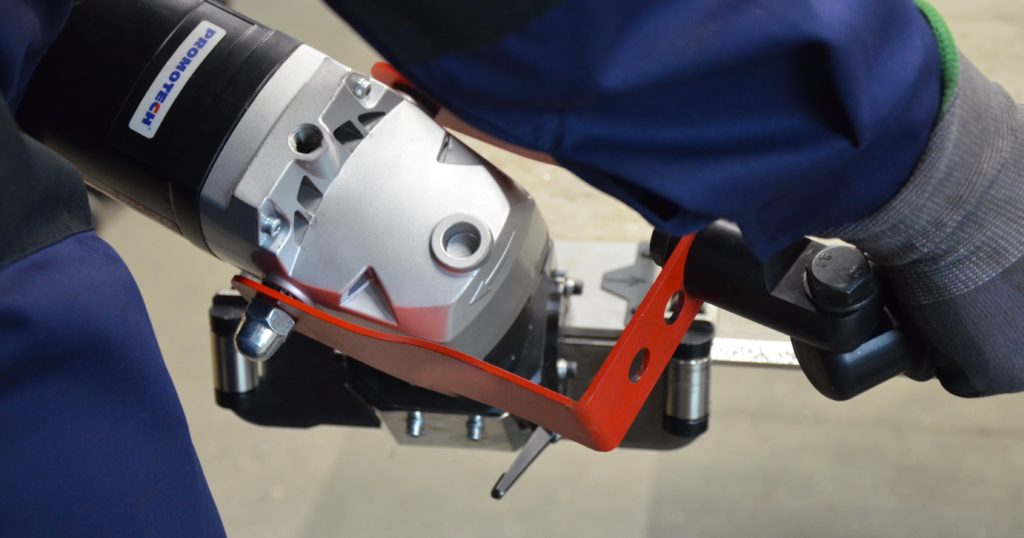

Better ergonomics and the comfort of work

BM-25S offers advanced functional design improvements, providing better handling and reducing operator fatigue. It is equipped with an ergonomic handle that enables comfortable positioning of the machine according to the machining angle, workbench height, and operator’s body type, ensuring optimal load distribution between the operator’s hands.

Safety

Improved safety features include a more robust guard system to protect the user from sparks and debris. BM-25S is equipped with one universal, basic chip guard and two dedicated guards: one for 30° bevels and another for 45° bevels.

Heat Build-up Control

PROMOTECH offers HD-CUT eco-friendly cooling/lubricating products engineered for use in a great number of industrial metalworking applications. They are non-corrosive and provide excellent rust protection. Using coolant helps to reduce heat buildup, lubricate the cutting process, and improve chip evacuation, all of which are beneficial when working with stainless steel. It’s important to ensure that the coolant is compatible with the specific grade of stainless steel being machined and that it doesn’t cause any adverse effects on the material or the machining process.

Beveller for stainless steel application

To prevent steel contamination from previously machined materials, it is recommended to use a dedicated set of tools exclusively for stainless steel. The PROMOTECH BM-25S is specifically designed as a stainless steel beveller with contamination prevention in mind. It offers superior performance for stainless steel applications, along with enhanced ergonomic and safety features.