How to create j-groove weld preparation on plates and pipes?

Surface preparation is a vital step in the welding process to ensure the high quality, strength, and durability of the final weld. A J-groove bevel is used in welding for several important reasons, particularly when dealing with thicker materials or specific joint configurations.

J-groove weld preparation on both plates and pipes drastically reduces the bevel volume while providing optimal penetration of the weld into the material. The J-groove design typically requires less filler material compared to other bevel types, such as V-grooves. This can lead to cost savings on filler material and reduce overall welding time.

What is j-groove bevelling?

Welding surface preparation is a common welding practice that ensures the strongest possible weld. J-bevelling is the base for many types of welding joints (such as single-J, double-J, single-U and double-U). A J-groove weld preparation typically involves one side of the joint having a straight edge, while the other side is bevelled to form a “J” shape. The shape of the groove provides access for the weld to reach the root of the joint, ensuring better weld penetration and complete fusion between the base metals.

This type of bevel is mostly used on the end of the tubing, pipe, and boiler, but it’s also suitable for heavy metal walls. It is ideal for joints that will be exposed to high pressures or stresses, such as those found in pressure vessels, pipelines, and structural applications. No wonder J-bevelling is a preferred choice for heavy-duty and high-stress welding projects.

Why j-groove bevel?

The most important aspect of J-weld prep is that it drastically reduces the volume of the bevel. This is why J-groove bevel is the best solution for thick surface weld preparation. But there’s also the disadvantage of the J-groove – it’s difficult to do by hand. It’s not only about fatigue, but it’s difficult to keep a uniform J pattern manually. So, the application of even and quality J-bevelled surface requires a bevelling machine. Especially if it’s about a significant number of workpieces.

To receive a uniform J-groove requires high accuracy which is difficult to achieve manually. Therefore, a well-chosen J-groove beveller is the investment that lays the foundation for high-quality welds through smooth bevelling with no heat-affected zones or distortion.

How to choose a proper J-groove beveller?

Choosing the right beveller for J-groove weld preparation requires careful consideration of the material, thickness, bevel angle, portability, power source, and other factors. By assessing your specific needs and matching them to the features of available bevelers, one can select a tool that ensures precise, efficient, and high-quality weld preparation. The first step is to select a beveller designed specifically for the type of material you are working on — pipe bevellers for pipes and plate bevellers for flat surfaces.

Portable vs. Stationary

Portable bevellers, such as PRO-2 PB, PRO-5 PB or PRO-10 PB are usually more versatile and handy, making them ideal for fieldwork or smaller jobs.

Portable pipe bevelling machines are an irreplaceable solution if it comes to small pipes and tubes. Thanks to the self-centering expandable mandrel, beveller always perfectly aligns to pipe or tube. Wide range of replaceable tool bits enables J-groove bevelling as well as OD bevelling, ID bevelling and facing–off applications.

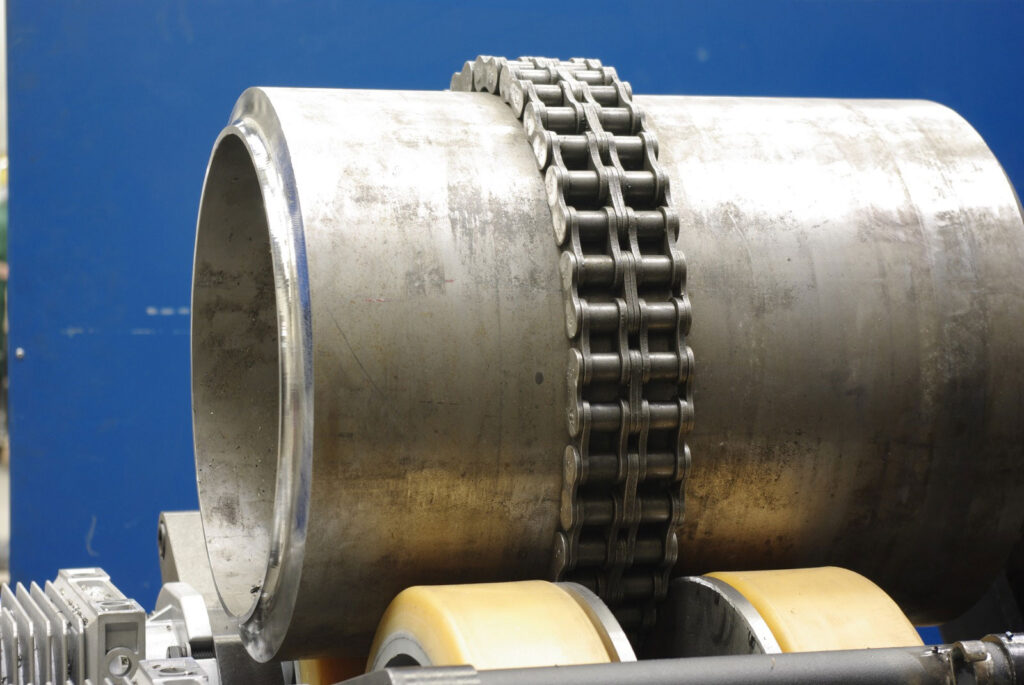

Stationary bevellers, on the other hand, provide more power and stability and are better suited for large-scale industrial applications. Machines, such as plate beveller ABM-28 or pipe beveller PBS-40 significantly eliminate the hard physical work of the operator and speed up the workflow.

Thickness and hardness of the material

The thickness and hardness of the plate or pipe will determine the required power and type of beveller. Thicker materials typically demand a more powerful beveller, capable of producing deeper and wider grooves. Adjustable depth and angle settings are particularly beneficial when working with materials of varying thicknesses.

J-bevel used as a surface preparation for welding thick plates and pipes reduces the required amount of filler material and, consequently, working hours to proceed with the welding. Additionally, by beveling one side of the joint, the welder can achieve better penetration and a stronger bond between the two materials.

Power Source: electric, pneumatic or battery

The choice of power source for a beveller typically depends on the work environment. Electric bevellers are the most commonly used. However, in settings where sparks from electric tools could pose a hazard, pneumatic bevellers are a preferred solution. For fieldwork or remote locations, a battery-operated beveller, which eliminates the need for power outlets, is an ideal choice. Additionally, reducing the number of cables lying around, enhances workplace safety. With machines powered by CAS, the same CAS battery can be used with over 300 machines from more than 40 brands.

In the situation when one works in many various settings, bevellers such as PRO-2 PB or PRO-5 PB free us from making this decision. Depending on site conditions, they can be operated with all three sources: a high quality powerful pneumatic motor, top quality high torque electric motor or CAS battery drive.

How to prepare J-bevel?

Clean the Surface

Like any other weld surface preparation, also j-groove weld preparation starts with cleaning the surface to remove contaminants such as oil, grease, dirt, rust, paint, and mill scale. These impurities can cause weld defects, such as porosity, inclusions, and lack of fusion, which compromise the integrity of the weld. Use appropriate cleaners – solvents or degreasers designed for metal surfaces.

Prepare the Groove with a dedicated plate and pipe bevelling machine

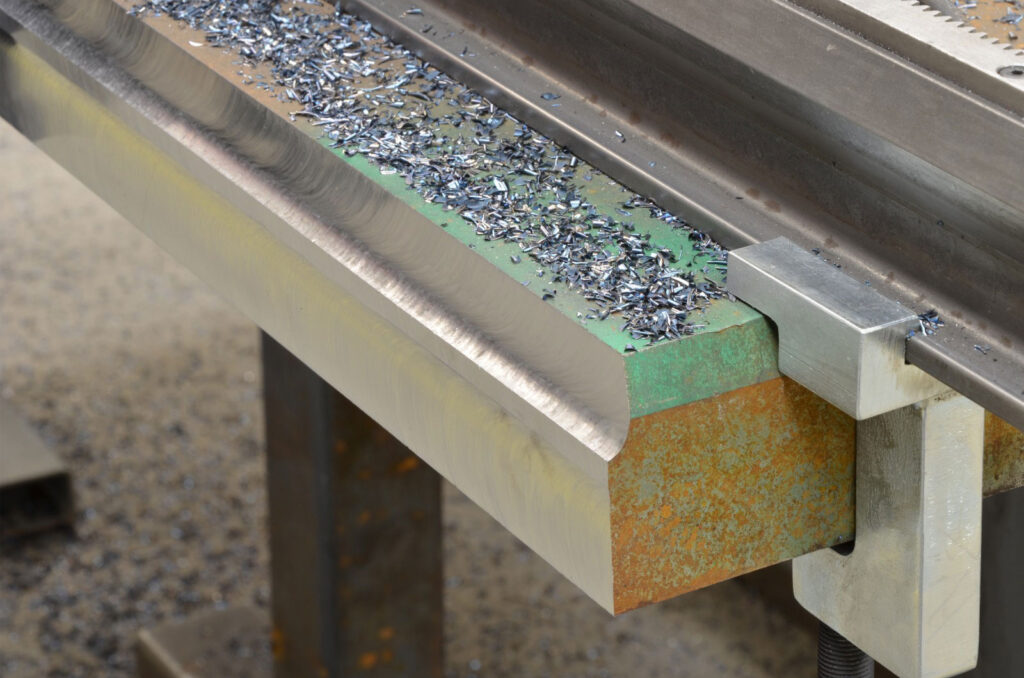

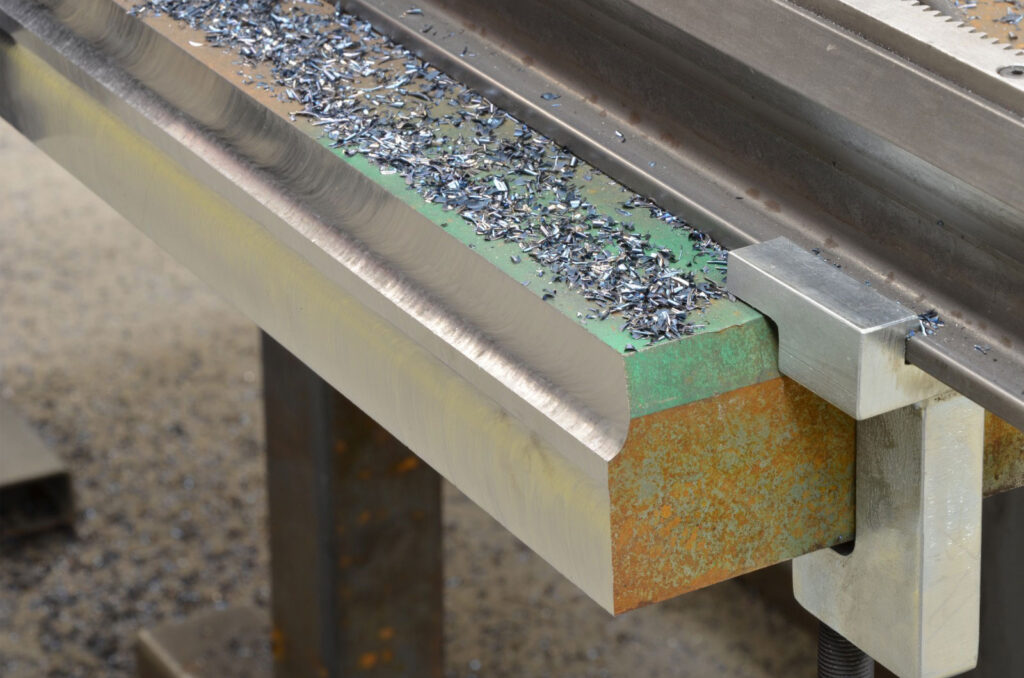

Mark the J-groove dimensions on the surface according to the weld specification and with the dedicated solution, cut along the marked line. The first cut should be shallow, setting the basis for the groove. Bevel one side of the pipe to create the “J” shape. A specialized pipe beveling machine can ensure a consistent bevel angle. The opposite side of the groove should remain perpendicular to the pipe’s surface. The groove should have a smooth, even shape to facilitate proper weld penetration and fusion.

Remove any burrs, sharp edges, or irregularities along the groove. This step is important to prevent stress concentrations that could weaken the weld. Make sure that the pieces being welded are properly aligned and fit together neatly. Otherwise, it may lead to weld defects such as poor penetration or excessive distortion.

J-groove bevel is chosen for its ability to enhance weld quality, reduce material usage, minimize distortion, and provide strong, durable welds in demanding applications. It is particularly useful in situations where deep penetration and fusion are required, making it a preferred choice for heavy-duty and high-stress welding projects.

Compare our portfolio of plate and pipe bevellers to find the one that best meets your needs and expectations >>

Read more about CAS battery system >>