Multi task pipe beveller and flange facer

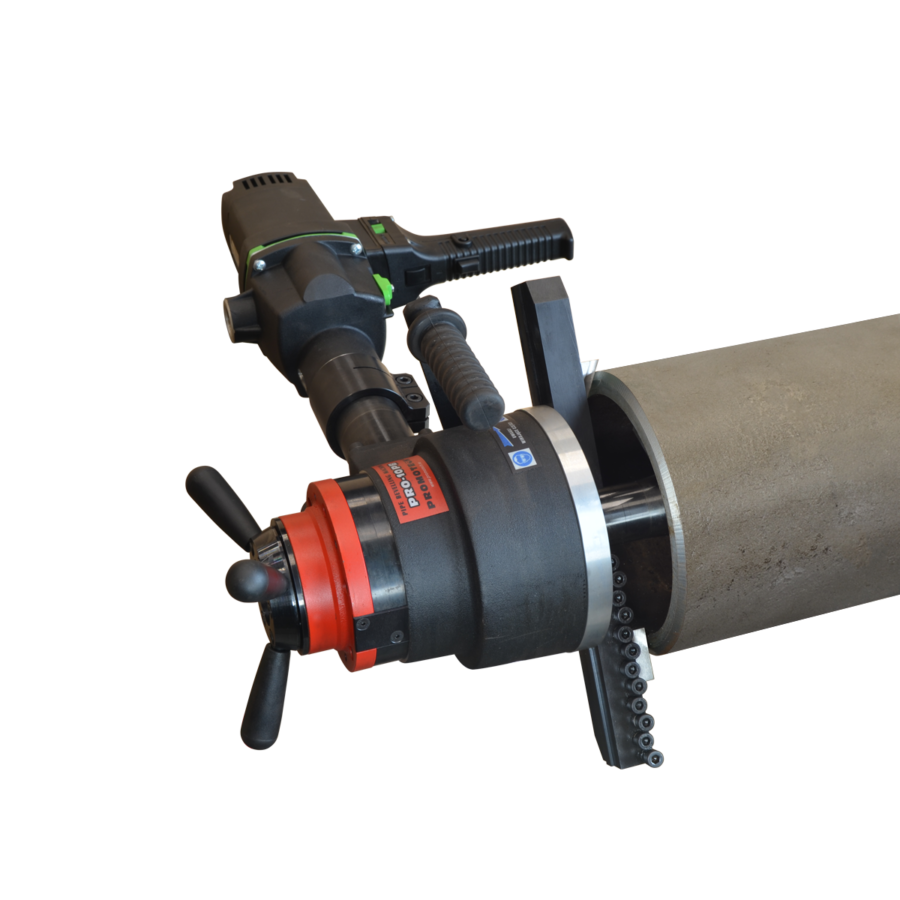

PROMOTECH PRO-10 PB portable pipe beveller and flange facer stands out as a robust and versatile solution. Engineered for high-performance pipe preparation, especially in industries where high precision is critical, such as shipbuilding, oil and gas industry, and construction. Meet the multi-purpose PRO-10 PB pipe beveller.

What can PROMOTECH PRO-10 PB do?

Designed for portable use in various pipe machining operations, the PRO-10 PB enables precise milling OD bevels, root faces, and ID counterbores, ensuring uniform wall thickness around the joint and full weld penetration, which are critical for high-quality welds.

Why is it worth beveling pipes?

Beveling is a process used to prepare metal for a welded seam by cutting a slope at an angle on the edge of the metal. PRO-10PB professional beveller ensures superior and reliable preparation for welding operations, elevating both your productivity and quality standards. By bevelling pipes one creates a larger contact surface for the welding joints, allowing a stronger and more durable connection. Moreover, it helps distribute stress more evenly across the weld, significantly reducing the risk of cracks and failures.

Unmatched Versatility

PROMOTECH PRO-10 PB is designed to mill pipes made from diverse materials: carbon and stainless steel, aluminum alloys, and copper-nickels. What is more, with a range of standard and custom-made tool bits, it can handle wide range of pipe and tube applications.

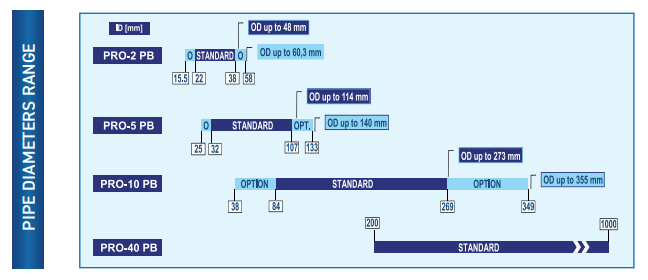

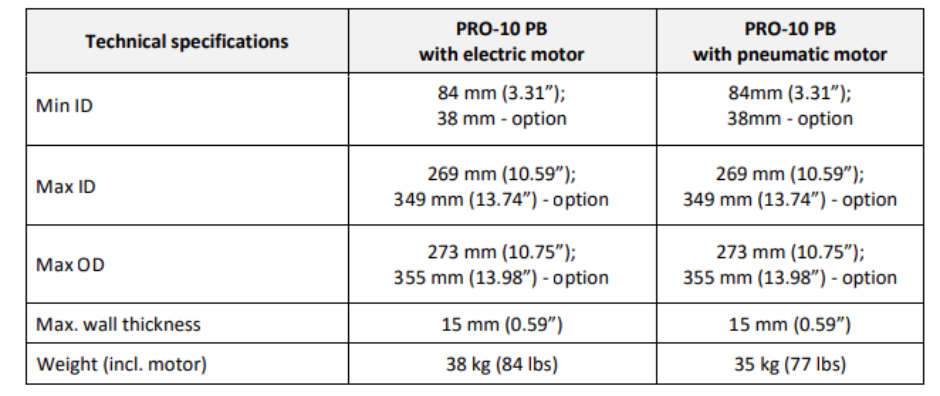

Multi-use PRO-10 PB enables external and internal beveling, internal calibration, and facing pipes with inner diameters from 84 mm to 269 mm. With optional accessories, its operating range extends from a minimum inside diameter of 38 mm (1.5”) to outside diameters up to 355 mm (14”).

Optional attachments allow one to face pipe flanges with diameters ranging from 90 to 508 mm (3 35/64-20″) and to bevel oval pipes from 126 mm to 296 mm (4 61/64-11 21/32″). Flange facing helps to create new mating surfaces that ensure a perfect seal and helps the flange to be less susceptible to leaks.

Additionally, J-bevel tool bits can be used to achieve high welding efficiency on thicker-walled pipes.

Single-Operator Convenience

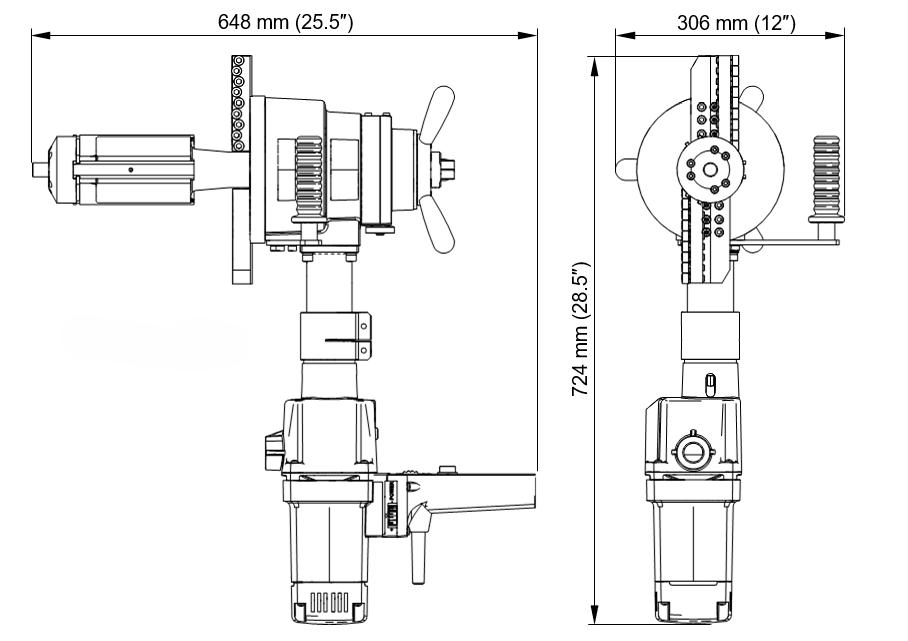

Designed for single-operator handling, PROMOTECH PRO-10 PB beveller is perfect for onsite tasks, even in challenging positions. The spindle disc, equipped with two tool bit holders, offers a stable and less stress-sensitive operation, further enhancing the tool’s efficiency. Optional accessories PRO-10 PB allow installing three tool bits at the same time.

Self-Centering Expandable Mandrels

Maintaining consistent positioning is critical for uniform bevels. The PRO-10 PB beveller comes equipped with self-centering expandable ID mounted mandrels. They ensure the beveller stays firmly in the center, providing a stable and precise alignment for the beveling process.

Self-centering mandrels simplify the setup, allowing quick transitions from one pipe / tube to another across multiple machining operations, thereby increasing overall productivity.

Choice of Pneumatic or Electric Motor

Depending on users preferences, needs and onsite conditions, PROMOTECH PRO-10 PB offers the flexibility between a powerful pneumatic motor and a high-torque electric motor. Both options provide the same range of functionalities.

In hazardous, explosive environments, pneumatic motors can be safer due to the absence of electrical components that might cause sparks. They also often provide higher torque, ideal for heavy-duty applications, especially if compressed air is already available at the location.

On the other hand, electric motors are quieter and require less maintenance, but need a location with reliable electrical power. Having the choice, PRO-10 PB users can select the motor type that best suits their specific work environment and requirements.

Conclusion

The PROMOTECH PRO-10 PB combines robust design and multi functionality, making it a versatile and reliable solution in the demanding field of pipe preparation. Even in shipbuilding, oil and gas industry, or construction, this tool provides high-performance, precision pipe bevelling and flange facing. Versatility at its best.

Check PRO-10 PB product site >>

Are you interested in the PROMOTECH portable pipe bevelling machines and how they can enhance your projects? Please, contact us >> We’re here to provide you with all the details you need.

“As an engineer constantly working with various pipe materials and diameters, I find the PROMOTECH PRO-10 PB to be an invaluable tool. Its versatility in handling both internal and external beveling on materials like carbon steel, aluminum alloys, and copper-nickels allows me to achieve precise and consistent results regardless of the materials I use,” says David Thompson, a seasoned engineer at NeoFab Solutions, a cutting-edge manufacturing company. David recognized the potential of the PRO-10 PB Portable Pipe Beveler & Flange Facer and integrated this machine into NeoFab’s production line.

“Also self-centering expandable mandrels proved to be very handy as they allowed for quick and precise alignment, significantly reducing setup times and enhancing overall productivity.” adds Dave.

David “Dave” Thompson

Engineer, NeoFab Solutions