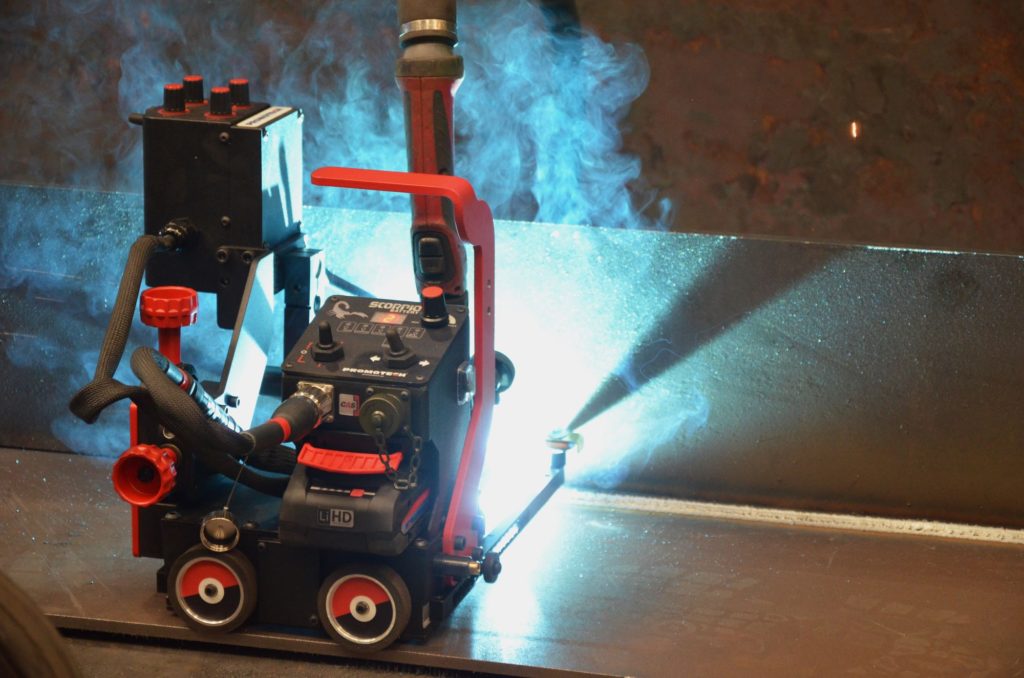

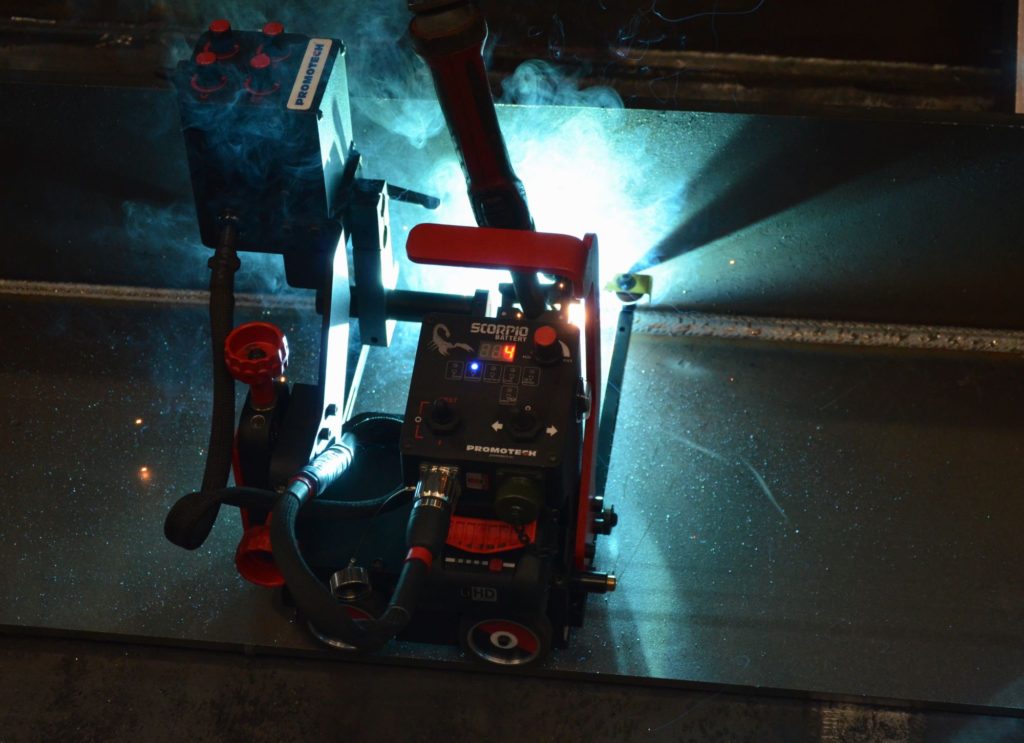

PROMOTECH is presenting a new programmable and cordless welding tractor – SCORPIO BATTERY. It can carry MIG/MAG torches and is designed for performing butt and fillet welds in both stitch and continuous welding modes. Its 4-wheel drive system with magnetic traction ensures stable travel.

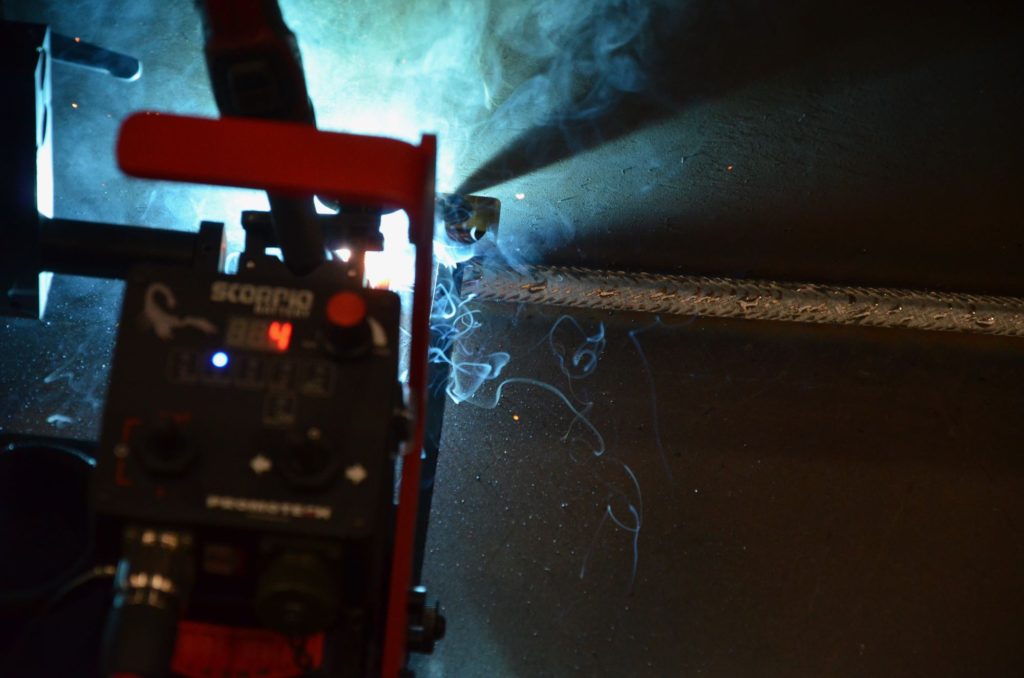

Welding tractors, such as the SCORPIO BATTERY, not only increase welding efficiency but also minimize the risk of human error, resulting in more uniform welds. Travel speed control and stabilization enable precise configuration of weld bead geometry to individual requirements, reducing costly over-welding and decreasing filler metal consumption.

Welding patterns and stitch welding can be programmed by entering parameters such as weld length, skip length, and PRE and POST crater filling. A convenient multifunctional LED display provides real-time information on travel speed, units, welding settings, and diagnostic messages.

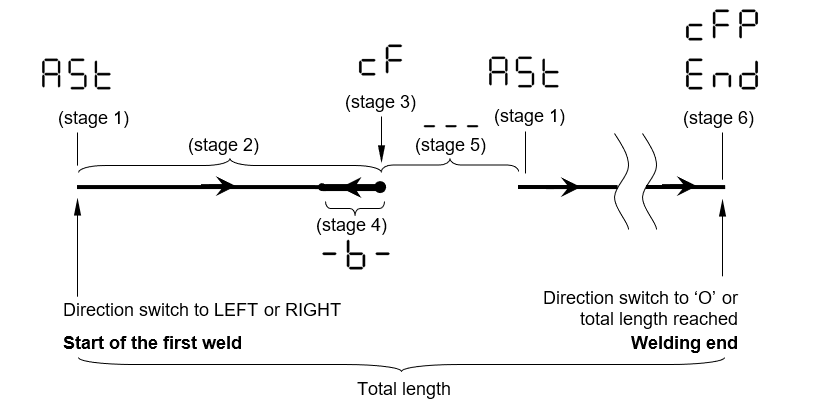

PRE and POST crater filling

Crater filling helps to avoid the formation of cracks at the start (PRE) and the end (POST) of the weld. This way we achieve a continuous and uniform weld, which is crucial for maintaining the structural integrity of the joint.

Stage 1 Arc stabilization and crater filling at the beginning of the weld

Stage 2 Tractor moves with the set speed and creates the weld of a defined length

Stage 3 Crater filling at the end of the weld

Stage 4 Back weld (Reverse filling length)

Stage 5 Tractor skips between welds.

Next steps 1 ,2, 3, 4 and 5 are repeated until total required length is reached

Stage 6 Final crater filling (the end of welding procedure)

In addition to delivering high-quality welds, the Scorpio Battery powered by a CAS battery, also offers the convenience of cordless mobility.

CAS Cordless Mobility

Cordless Alliance System (CAS) is a cross-brand power battery pack system of over 40 power

tools manufacturers. It allows to effortlessly swap batteries and chargers between different tools, as long as they’re part of the CAS alliance. Everything fits everything: machines, batteries, and chargers.

LiHD (High Density Lithium Ion) battery provides enough power for handling even the toughest applications,with no cables. With dual batteries one can continue workflow without interruption. Intelligent battery management ensures long-lasting performance. Currently, PROMOTECH offers one cutting unit and three welding tractors that can be powered by the same 4.0 AH battery: Dragon Battery, Scorpio Battery, Gecko Battery and Mini Spider Battery.

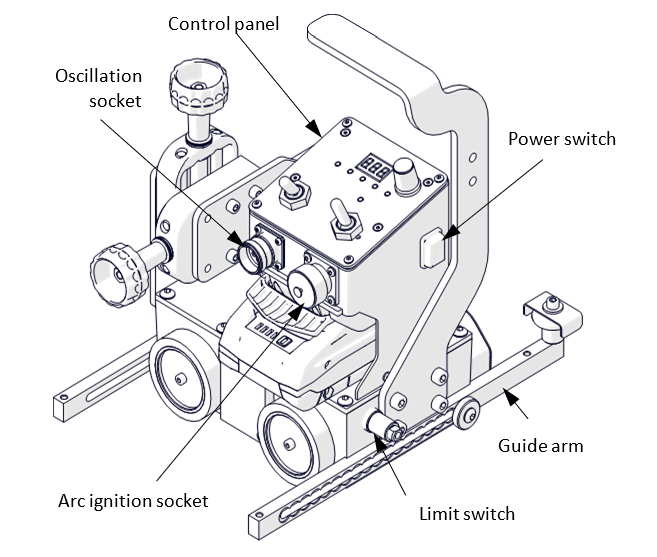

Optional Accessories

Optional accessories further expand the tractor’s capabilities, enabling welding with oscillation, using torches with larger diameters, and using two torches at the same time.

Optional weave welding

Scorpio Battery offers simple programming of welding patterns and stitch welding parameters. For welding thicker materials, wide joints, or gap bridging, it can be equipped with the optional pendulum oscillator that provides precise control over weave width, weave speed, and left/right side dwell times.

This allows for effective coverage of a gap area with each pass, resulting in high-quality weave welds. Weave welding is particularly beneficial for wide joints where a straight pass may not fully fill the gap or achieve the required penetration. In multi-pass welding operations, weave welding can be employed to build up thicker welds, enhancing joint strength, especially in structural applications.

SCORPIO BATTERY has a built-in socket to power the oscillator unit, eliminating the need for a separate power supply and maintaining the convenience of cordless mobility.

Benefits of using two torches

By using the arc ignition cable plugged into the arc ignition socket, Scorpio Battery can control two torches at the same time. Using dual torches boosts productivity across various industrial welding applications.

A welding tractor equipped with two torches can complete welding tasks in half the time compared to using a single torch. Additionally, by evenly heating both sides of the joint, dual torches enhance penetration and fusion, resulting in stronger, more durable welds. Uniform heat distribution across the weld joint can also reduce any risk of distortion, minimize the need for rework, and decrease material waste, ultimately leading to overall cost-effectiveness.

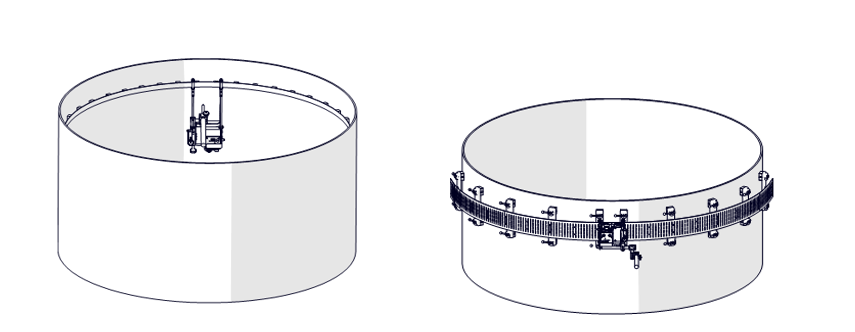

Work on curves

Scorpio Battery can also be easily adapted for circumferential and irregular surface applications down to min. convex radius of 1000 mm (while working outside) and concave 1250 mm (while working inside).

The use of optional flexible guides allows running Scorpio Battery along longer tracks, on pipes and tanks. A single flexible guide is 1.85 m long and its minimum curve radius is 1 m.

Optional flexible trackway set, on the other hand, allows the tractor to move on flexible rails that are clamped to plates, pipes, or tanks. A single flexible rail is 1.88 long and its minimum curve radius is 1.25 m. Each rail can be secured to ferrous surfaces using narrow magnetic units, or to non-ferrous surfaces using vacuum units.

In summary, the SCORPIO Battery welding tractor delivers consistent, high-quality butt and fillet welds in both stitch and continuous welding modes, reducing material waste and minimizing the need for rework. Its compatibility with CAS batteries ensures flexibility across multiple tools and machines, while its optional accessories enhance its versatility and efficiency.

Scorpio Battery powered by CAS combines advanced programmability, cordless convenience, and robust performance to meet wide industrial welding needs.