Welding Slang – People, Equipment, Techniques

Welding slang is the internal language that reflects practical knowledge, daily experiences, and often carries a touch of informal humour. Only after mastering welding slang does one truly feel like “one of their own”—an authentic member of the welding community.

Whether you’re a professional or a greenhorn, learning these terms will not only help you understand the culture but also earn you a nod of respect from your fellow welders.

In this article, we’ve gathered some of the most popular and widely used welding slang terms that describe the people in the trade, the equipment they use, the everyday situations, and techniques they face. Slang related to common welding mistakes and defects is a whole category of its own. Soon we will publish a separate article to cover it in full. Stay tuned for that one!

People

In the welding trade, nicknames may show the experience, skill, or sometimes… painful lessons.

A “Golden Arm” is the welder everyone wants on their team—someone whose precision and control produce flawless beads. If that talent is used to do demanding work from the inside, often in tight, uncomfortable, or high-risk environments – one may earn a slightly humorous and respectful nickname of the “Golden Goose”.

Someone who goes inside to lay the golden eggs (or in this case, golden welds!). Then there’s the “Meat Hand,” originating from the expression “bead hand” and meaning a skilled welder capable of smoothly executing root passes on X-ray-quality pipe welds without breaking a sweat, even in challenging conditions.

A friendly tip: if you’re aiming for ‘Golden Arm’ quality welds, take a look at PROMOTECH range of welding carriages – they ensure perfect gun guidance and reduce welder’s fatique.

You might also meet a “Shield Arc’er” or “Stick Rider”—those proud to wield the SMAW (Shielded Metal Arc Welding) torch. On the other hand, the welder who relies more on strength than skill may be called ”Shoulder to the Holder”. The welder’s helper is also called a “Grasshopper”. New recruits often earn the title of “Greenhorn”, “Green”, “Rookie”, or “Warm”—still heating up, learning the ropes.

Whereas a welder suffering from the painful photokeratitis (flash burned eyes, “Arc Burn”, or “Arc Eye”) is called a “Potato Face”. Why? Because putting sliced raw potatoes on the eyes is said to be a great remedy in such situations.

In welding slang, a “Brother-in-Law” refers to two welders working on the same weld joint at the same time, typically on large-diameter pipe that needs to be welded all around. ”. Like actual brothers-in-law, the two welders are related not by blood, but by sharing the same weld joint. To save time—or meet strict deadlines—two welders might start on opposite sides of the pipe, weld toward each other simultaneously, meet in the middle and “tie in” their welds. This synchronized approach is called a “Brother-in-Law weld”

Photo: Instagram upinsmoke welding apparel

Equipment and Common Situations

Whether it’s about precision, improvisation, or recovery, welding slang has a phrase for every element of the process. Forget calling it a “welding torch”—on the job site, it’s just “a gun” or “a stick“, depending on the process. Working with MIG? That torch becomes a whip, and you might hear someone mention their cup, referring to the TIG nozzle. Shielding gases? Whether it’s pure argon or a blend, most welders simply call it argon.

When it comes to setups, a “rig” is more than just a truck—it’s a mobile command center, complete with all the welder’s tools and gear. Before rolling out, everything must be “highway tight” – safely secured. On-site, tools like the “third hand” help hold components in place before tacking, and some welders work lying on “a mortar board (or mud board)” to stay out of the muck during pipeline jobs.

Someone might shout, “Put me on Maxine and 100!” which means cranking the machine’s knobs all the way up to max output.

Slang for welding techniques

For starters, an Arkansas Bell Hole refers to a challenging pipe weld performed in the 6G position, where the pipe is fixed at a 45-degree angle and the welder must work all around it.

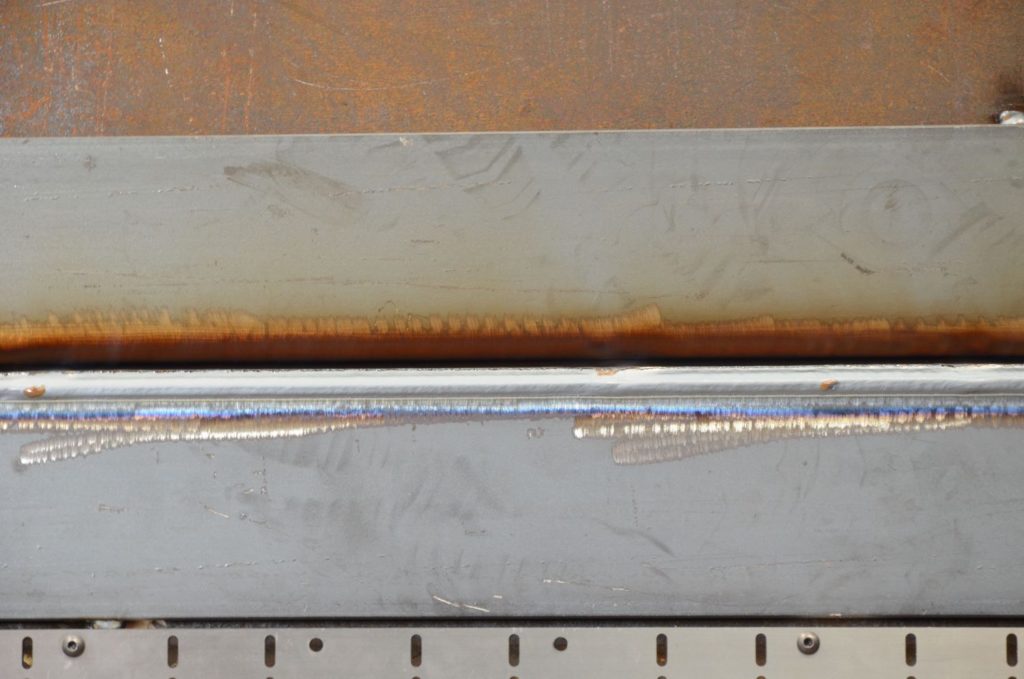

The multiple pass weld begins with a root pass, the crucial first weld that fuses the base metals, followed by a fill pass, and finally the cap — the finishing layer, which can be done as a straight stringer bead or a wider weave.

What happens when the root pass has been ground down too thin — sometimes by a worm (a grinding tool or technique used to clean up the root)? Instead of starting over a welder might say: “Throw a skater in there”! This means a smooth, controlled way of adding a corrective pass on top of an existing one, to reinforce the joint without disrupting the overall weld flow. The term captures both the precision and finesse needed to correct a weld without making a mess of it.

Welders talk about going downhill (welding vertically from top to bottom) or uphill (from bottom to top).

TIG welders might use “walking the cup” – a rocking motion to create smooth, even weld that look like “a stack of dimes”—the gold standard of weld appearance. A truly perfect finish might even be described as “dime wide and nickel high.” And if the weld needs a little cosmetic help? Just run a cheater bead over the top to tidy it up or hide minor flaws.

Welding slang is not just about the looks, but sounds, too, and experienced welders know how to listen. When your machine starts making popcorn sounds, that usually means something’s wrong — poor settings, dirty material, or gas issues. On the flip side, if you hear a steady, satisfying sizzle, congratulations — you’re frying bacon, the sign that your MIG setup is just right.

In the world of welding, knowing the craft is only part of the journey. To truly feel like “one of their own,” welders must also master the unique slang that defines the trade. Welding jargon is more than just words—it’s a reflection of practical knowledge and shared everyday experience.

If you’re striving for “Golden Arm” quality welds – precise, consistent, and visually flawless – make sure to explore our advanced range of welding tractors.