All Shades of PROMOTECH’s DRAGON: Choose a Perfect Set Up.

The PROMOTECH DRAGON family of tractors offers high-performance solutions for plasma and oxy-fuel cutting and bevelling, adaptable for use in the workshop or out in the field. DRAGON thermal cutting and bevelling tractor is available with 115–230V, 50–60 Hz, 42V AC, or 18V DC battery power supplies, providing flexibility for different work environments:

- DRAGON (115–230V, 50–60 Hz)

- DRAGON BATTERY (18V DC)

- DRAGON HS (115–230V, 50–60 Hz)

- DRAGON 42 V (42V AC)

Engineered with productivity, precision, and reliability in mind, PROMOTECH DRAGON family of tractors delivers accurate cuts and bevels, significantly reducing fit-up and grinding time. To meet the diverse demands of both plasma and oxy-fuel cutting and bevelling operations, one can choose from several versions: the standard DRAGON, DRAGON HS (High Speed), DRAGON 42V AC, and the latest addition – DRAGON Battery, a cordless version powered by CAS battery. This way DRAGON family of carriages can provide perfect foundation for high-quality welds across a wide range of applications.

Let’s begin by examining the features common to all versions.

The core of DRAGON Family

In case of welding and cutting carriages, PROMOTECH’s commitment to high quality and durability is reflected in the extended 3-year warranty, starting from the date of the sale to the end-user.

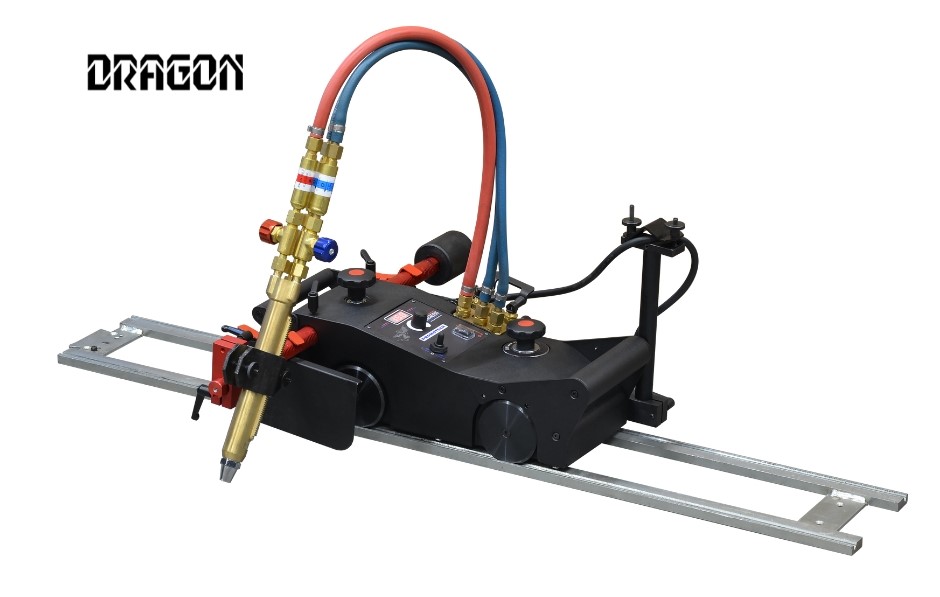

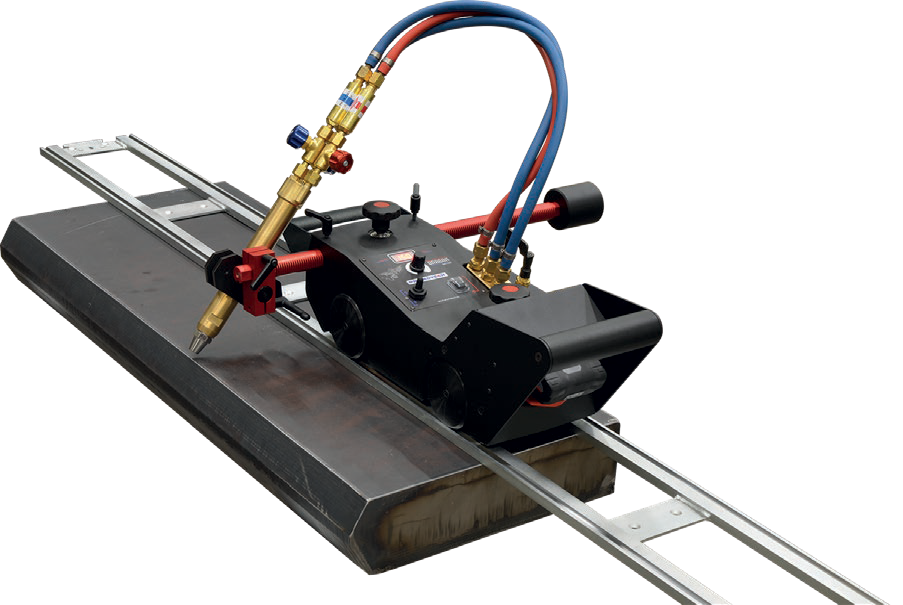

All PROMOTECH’s DRAGON tractors are engineered for plasma and oxy-fuel cutting and bevelling using torches with a diameter of 28–35 mm.

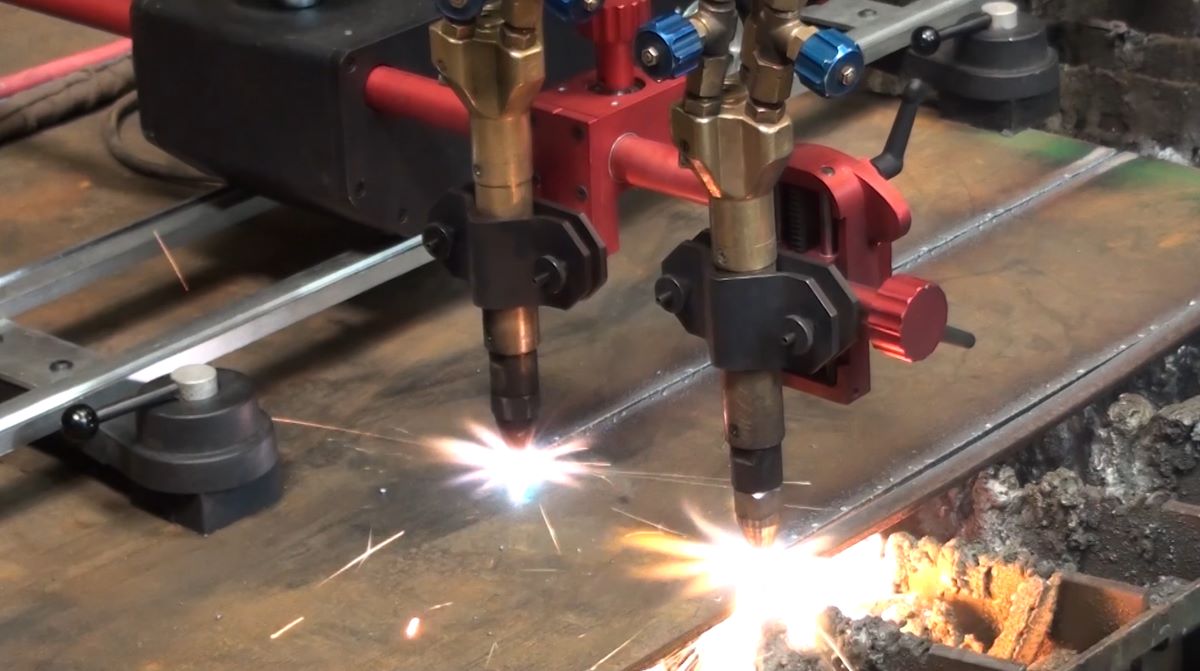

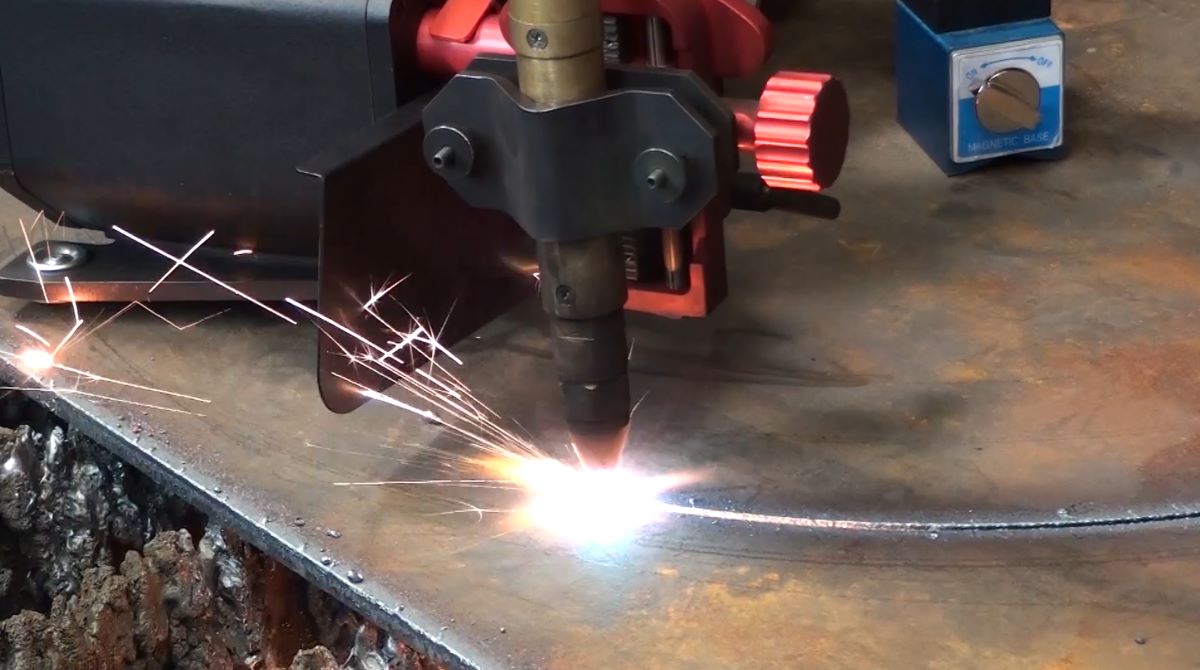

Digital speed control and stabilization enable high quality cuts and bevels up to 45° on various steel surfaces. A wide range of optional accessories—such as machine torch holders, manifolds, and circle cutting attachments—further expand its adaptability to various tasks. Accessories allow using torches with different diameters, using two torches at the same time, and cutting holes with radius between 240 and 2500 mm.

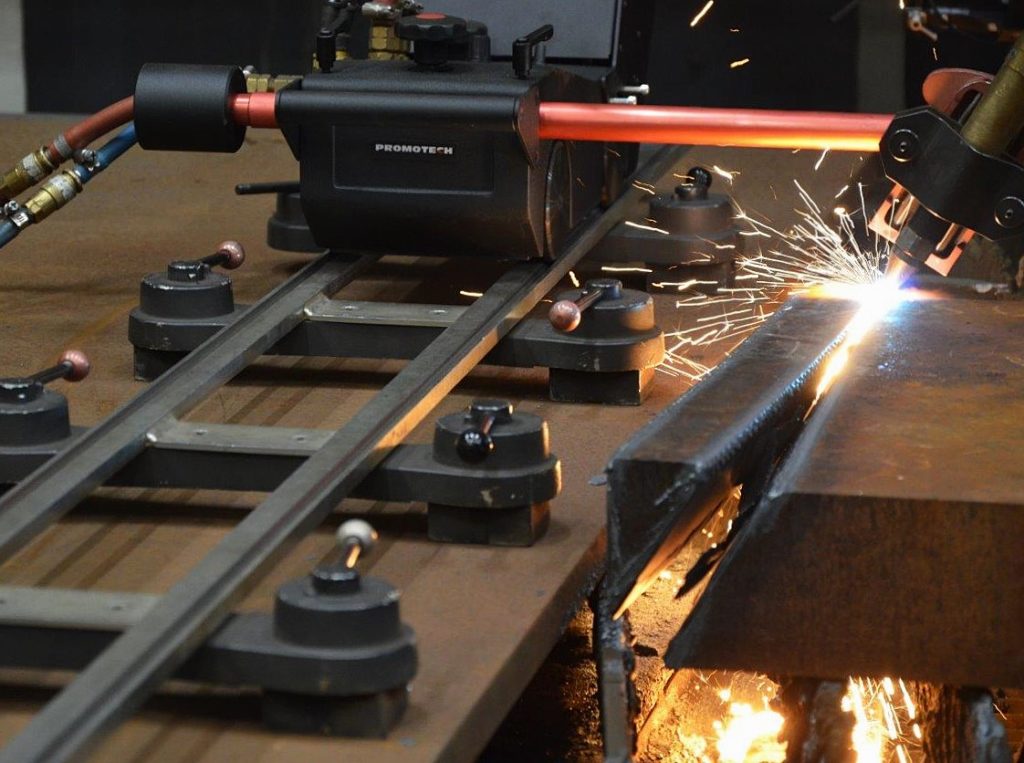

One of the standout features is their remarkable flexibility. They can operate either on a rail or directly on the workpiece. The tracks can be securely fixed to ferrous materials using magnetic units, or to non-ferrous materials with vacuum system. Single rail section is 1800 mm in length and the V-groove centerline of 152 mm. For longer workpieces, additional track sections can be easily connected using a 4 mm hex wrench and a connecting plate, allowing smooth adjustment to the required run length.

User comfort and convenience were not overlooked. The LED display provides clear readouts of both actual and set speeds, along with report messages. The quick drive release switch allows for fast and easy decoupling and repositioning of the machine. Ergonomic handles on both sides make the tractor easy to carry and maneuver.

All these features come together to make PROMOTECH DRAGON plasma and oxy-fuel cutting and bevelling tractor a versatile, user-friendly, and high-performing solution. To meet the specific needs of each task, various versions of Dragon were introduced into PROMOTECH’s offer.

CAS Powered Cordless Mobility: DRAGON Battery

The DRAGON Battery is a cordless version designed for maximum mobility and convenience, making it perfect for fieldwork. It offers all the common features of the DRAGON family, including the ability to cut and bevel steel at various angles, while ensuring high-quality, consistent results with minimal setup.

Powered by a CAS 18V DC battery, it eliminates the need for a mains power connection, reducing clutter and making it easier to work in remote locations. The LiHD (High Density Lithium Ion) battery, supported by intelligent battery management, ensures maximum power availability for an extended period. With two batteries one can easily swab them and continue without interruption. Meantime, the other battery is being charged.

Cordless Alliance System (CAS) is initiated by Metabo, cross-manufacturer coalition that gathers leading power tool brands. As a result, CAS batteries and chargers are compatible with other PROMOTECH battery-powered machines, including bevellers and mag drills, and over 300 machines from more than 40 brands.

More about benefits of Cordless Alliance System (CAS) >>

High Speed for Large Scale: DRAGON HS

The DRAGON HS is a carriage specifically designed for high-speed oxy-fuel or plasma cutting and bevelling operations. With a travel speed of up to 300 cm/min, it significantly increases plasma cutting capacity, making it ideal for large-scale operations. The carriage travels horizontally on the workpiece or track tilted up to 10°.

Check PROMOTECH Dragon HS specification >>

Low Voltage for Safety: DRAGON 42V

42V tractors are preferred for several key reasons, mainly due to safety, efficiency, and specific power requirements. Shipbuilding, offshore, and heavy industries – these industries often use carriages in harsh environments where moisture and other factors increase the risk of electrical hazards. The lower voltage helps minimize the risk of electrical shock, providing better protection for operators while maintaining outstanding performance.

The DRAGON 42V version offers a reliable and consistent power supply through its 42V AC connection that meets stricter safety protocols.

Thermal cutting and bevelling with DRAGONS

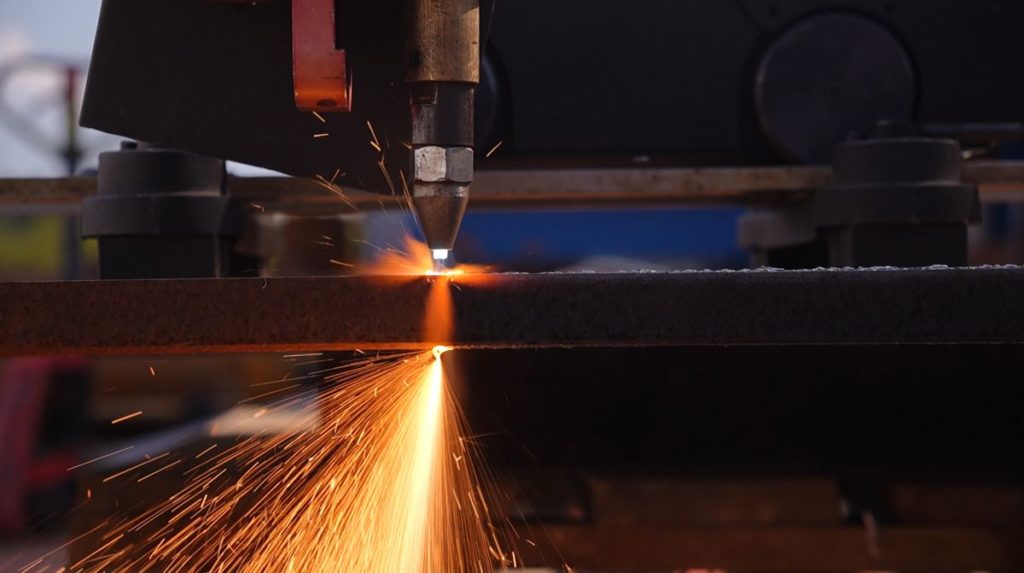

Even in harsh environments, from construction to shipbuilding, plasma and oxy-fuel cutting and bevelling deliver excellent results. Thermal methods allow for rapid material removal, making them much faster than mechanical methods like sawing or grinding. This is especially crucial in large-scale industrial operations where time is a significant factor. Cutting through thick metals with ease, PROMOTECH’s Dragon delivers clean, precise cuts with minimal finishing needed, saving both time and effort.

Whether you prioritize high-speed efficiency, mobility, safety in hazardous environments, or compatibility with various power supplies, PROMOTECH DRAGON family delivers precision and reliability across all versions.

From the standard DRAGON, cordless freedom of the DRAGON Battery, 42V low voltage safety to the high-efficiency capabilities of the DRAGON HS, each model is crafted to meet the diverse demands of today’s industrial sectors.