HSS and TCT annular cutters for milling in steel

When it comes to industrial drilling, precision, efficiency, and tool durability are the key. Annular cutters, also known as core drills, tube drills, or hollow drills offer numerous advantages when working on diverse metals and in various applications.

As they allow for drilling large holes in solid material without the need for pre-drilling, annular cutters are a highly effective alternative to traditional twist drills. Let us explore the features and benefits of using annular cutters.

Metric Annular Cutters: HSS and TCT

Available in metric sizes, these cutters come in two main types: HSS (High-Speed Steel) and TCT (Tungsten Carbide-Tipped).

HSS cutters are made of high speed steel with multi angle -cutting geometry designed for ply-cutting, for improved chip removal. Their cutting edges can be resharpened, extending the lifespan of the tool and reducing replacement costs.

TCT cutters incorporate special carbide tips with multi-cut geometry for ply-cutting, lower friction, and reduced damage. Like HSS cutters, they feature multi-cut geometry for enhanced cutting precision and efficiency. TCT cutters are known for their durability, especially when milling in harder materials.

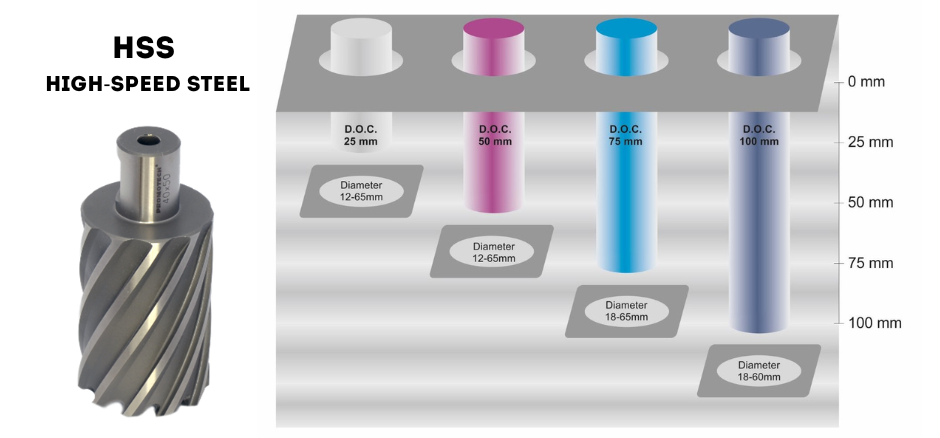

PROMOTECH HSS high-speed steel cutters are available in two cutting lengths, 1″ and 2″, ranging from ø 12 mm to ø 50 mm. Sizes 3″ and 4″ are available on request.

For diameters over ø 50 mm, we recommend TCT (Tungsten Carbide-Tipped) cutters with carbide-tipped teeth. Large TCT cutters, such as 200mm diameter, which are often used in PRO-200 ATEX drilling machine are available on request. Cutting length refers to the maximum material thickness that can be drilled through.

Both types of annular cutters use Weldon shanks, providing firm clamping for stable cutting and precise hole finishing. For HSS cutters up to 65mm or TCT up to 60mm, a Weldon 19mm (3/4”) shank is used. Whereas for cutters larger than 65mm – Weldon 31.75 (1 1/4”) shank is applied.

Why Do Annular Cutters Outperform Traditional Twist Drills?

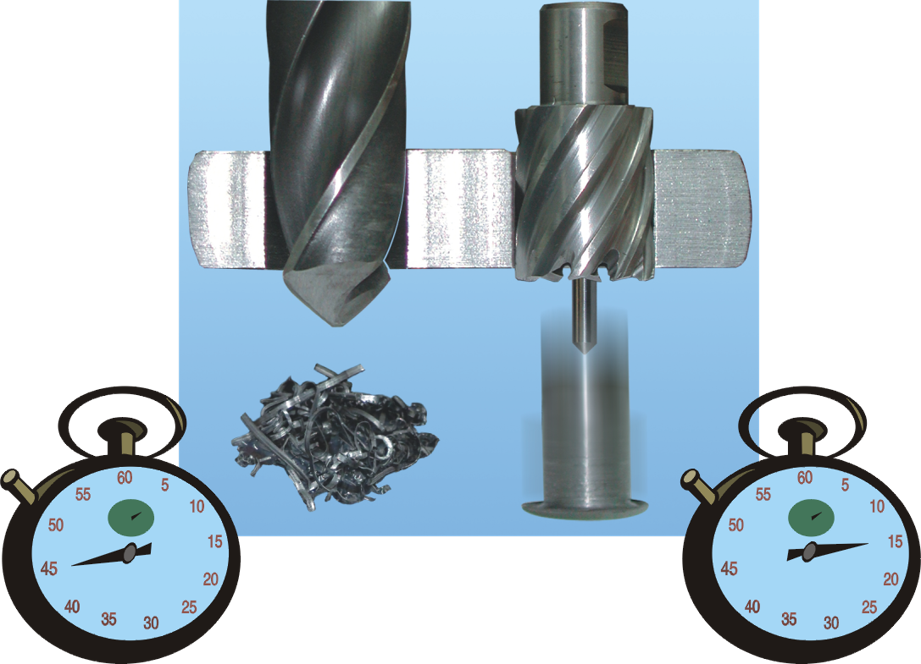

Unlike traditional twist drills, annular cutters drill open holes or overlapping holes (similar to slot-shaped holes) and leave a solid core intact. Such cylinder “slug”, received after cutting the hole with core drill, can be used as valuable material. Especially when one is drilling large-diameter holes in expensive, thick materials. Twist drills, on the other hand, shatter the entire hole into chips. This design reduces cutting resistance, allowing for faster, cleaner, and more precise holes with less energy and wear on your tools.

Reducing Time and Costs

Annular cutters eliminate the need for pilot holes and step drilling, significantly reducing time and cost of additional operations.

By cutting only the periphery of the hole, milling cutters usually require only 30% power of what a twist drill would need. Using an annular cutter on a drill with a power output of around 1600W can expand its milling capacity from a maximum ø 32 mm (for a twist drill) to ø100mm ( e.g. PRO-102 drilling machine).

At the same time, drilling efficiency increases significantly. For example, a hole with a ø 25 mm diameter in a 25 mm thick steel plate can be milled with an annular cutter in just 25 seconds.

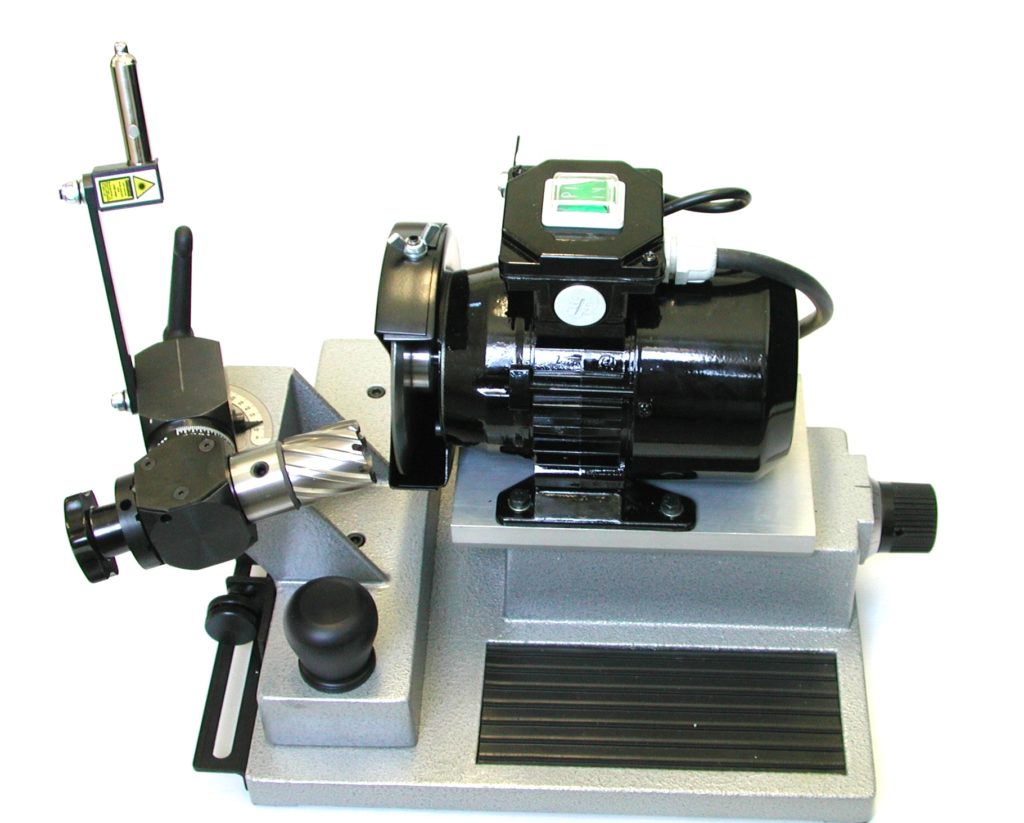

HSS core drills can be re-sharpened i.e. with annular cutter regrinding machine SM-101. Such process can save time and money, particularly if the customer is in urgent need for continued production drilling. Thanks to its solid construction, low power consumption, small dimensions, the machine can be used in any place.

SM-101 annular cutter regrinding machine is easy to use and offers a quick and simple setup with quick positioning of the cutting tool. Simple angle adjustment allows for precise alignment with desired geometry. Equipped with a diamond wheel, it delivers sharp, clean cutting edges, while the laser-guided alignment guarantees perfect positioning of the cutter with the cutting wheel for optimal performance.

Versatile and Efficient Solution

As annular cutters require less force for milling, they allow for use with smaller, more portable machines without sacrificing cutting capacity. What is more, annular cutters can drill on curved surfaces such as pipes and tubes, and can even create overlapping or open-edge holes, allowing for a broader range of applications.

Check PROMOTECH’s drilling machines >>

Annular Cutters in Industrial Applications

Annular cutters are commonly used in a variety of industries where portable precision drilling through steel, aluminium, or other metals is essential. These industries include:

- Manufacturing: In the production of machinery, automotive parts, and heavy equipment.

- Construction: In structural steel fabrication to drill precise holes in beams, columns, and other metal components for bolting and assembly.

- Oil & Gas Industry: pipelines, storage tanks, and metal structures during maintenance and installation work.

- Shipbuilding: metal ship components, whether for structural fabrication, repair, or modifications in marine environments.

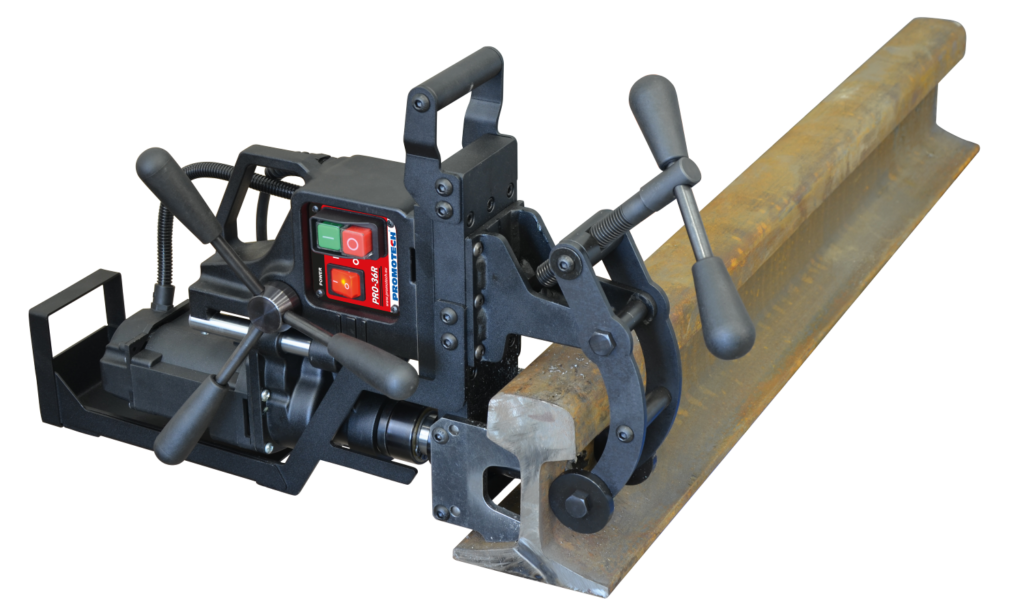

- Railway: in rail tracks, metal plates, and other components for maintenance and construction of railway systems. For this purpose, check PRO-36R, available in petrol, electric, and CAS battery powered versions.

- Automotive: In the automotive industry, annular cutters are used for drilling holes in car frames, parts, and equipment during assembly or customization.

- Metal Fabrication: in sheet metal, pipes, and other metal components for various fabrication projects.

- Infrastructure & Utilities: in the installation and maintenance of infrastructure, including drilling into metal supports, brackets, and structures for bridges, towers, and utility poles.

By removing only the material at the periphery of the hole, annular cutters drill holes up to three times faster than traditional twist drills. This efficient process significantly reduces the volume of material being cut and produces far fewer chips, making them the preferred choice in industrial and metalworking settings where speed and precision are critical.