Better safe than sorry. How to safely use metal working machines?

In the world of construction and manufacturing, precision and safety are crucial. Safe working space is not just a matter of efficiency, but a critical component in reducing the risk of accidents. Learning to recognize workplace hazards allows to prevent injury and work safely. These guidelines are only basic tips for less risky and more productive working environment.

Choose “Safety first” mindset. Start with some basic safety rules that can be applied to any metal working machine operation.

Location

Check if your working space is well-ventilated, well-lit and offers adequate space for operating with the chosen equipment. Make sure your operating area is clean, dry, and free from any clutter. Do not use your machines in explosive environments or near flammable materials unless they comply with special ATEX directives (i.e. drilling machine PRO-200 ATEX).

Inspect equipment

Always inspect your machines and accessories before use. Make sure that the machine has all parts and they are genuine and not damaged. Check for any signs of damage or wear and tear. Ensure the correct condition of the machine, power source, power cord, plug, control panel, and tools.

Remember that it is not safe or productive to use blunt or damaged tools.

Keep your workspace clean

Remove any obstacles or hazards from the working area, including idle keys, wrenches, loose clothing, or other items that could get caught in the machine. Keep the area around clear to prevent tripping or falling hazards. Connect the machine to the correctly grounded power source.

Keep in mind that machines should not be used on:

- rusty or uneven surfaces,

- steel plates covered in thick paint.

Personal Protective Equipment (PPE): googles, ear protection, gloves

Before starting any metal working operation, ensure that you and anyone else present are wearing the necessary PPE. Always wear goggles to protect your eyes from debris and hearing protection to reduce noise exposure. Wearing the sturdy work gloves to protect your hands is also a good idea. Never remove metal chips and strands with bare hands.

Jewellery and loose elements

Wearing items like jewellery, scarves, and clothes with loose sleeves can be hazardous when using a machine. Take off any jewellery, especially necklaces, bracelets, or long earrings, before starting a machine. If you have long hair, also make sure to tie it back.

Opt for fitted clothing that doesn’t have loose sleeves or fabric that could be caught by machine and cause severe injuries, including cuts, bruises, or even broken bones. Moreover, loose clothes can block your view or movement, reducing your ability to operate the electro tool safely and accurately.

Secure workpiece

Before using the machine for the first time, always read operator’s manual. Make sure that the specifications of the power source are the same as those specified on the rating plate.

Operating with metal working machines, it’s crucial to fasten them firmly and ensure that the workpiece is stable and will not move or shift during the operation. This stability is vital for precision, safety, and the overall success of your project.

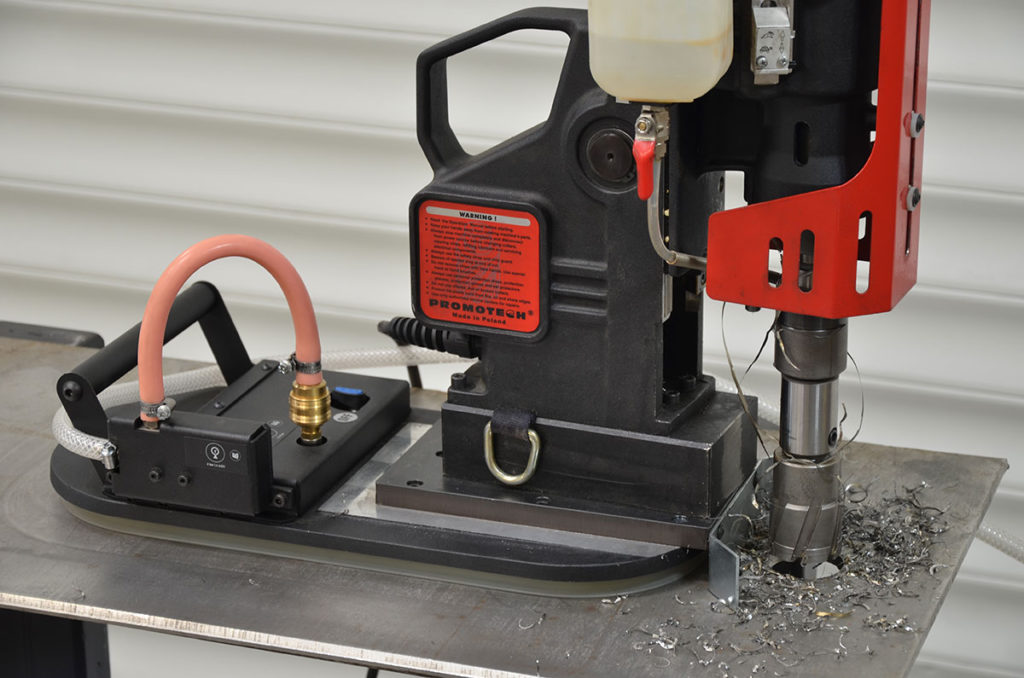

Most of PROMOTECH drilling machines are equipped with an electromagnetic base that enhances stability. This base quickly attaches the drilling machine to ferromagnetic surfaces. The electromagnetic force provides a secure hold, allowing for precise drilling without the risk of the machine moving or slipping. However, it’s important to be cautious when working on thin plates. The clamping force of the electromagnetic base is directly related to the thickness of the plate. Thinner plates may not provide the necessary magnetic pull, potentially compromising the stability of the machine.

Additionally, a safety strap is included to protect the machine from falling in case of a clamping loss. This security measure ensures that the machine remains attached to the workpiece even if the electromagnetic hold is lost. For non-ferromagnetic surfaces, an optional vacuum pad is available. This pad creates a strong suction force and allows to clamp the machine securely to a variety of surfaces.

Follow operating procedures

Never operate the equipment if you don’t know how to use it properly. Although common sense is an important feature, when using metal working tool always rely on the manufacturer’s operating instructions and safety guidelines.

Before starting to operate, check specified applications and recommended settings. Choose the appropriate accessories (size, condition) for the material and task at hand. Unplug the power cord before you install and remove tools. Before you start working, make sure that all elements are tightly seated.

Keep the machine in the proper conditions. Do not expose the machine to rain, snow, or frost. If the machine falls, is wet, or has any damage, stop the work and immediately send the machine to the service center for check and repair. Repair only in a service center appointed by the seller.

To avoid wire breaks and to keep your machine in good shape for long time, don’t hold or carry the machine by the power cord and do not pull the cord. This can cause damage and electric shock. Always use the handle for that purpose.

Most of all, remember to exercise caution and diligence throughout the process.

Supervision and proper training

Make sure that anyone operating metal working equipment has received proper training and supervision. Never allow inexperienced or untrained individuals to use power tools unsupervised. Keep untrained bystanders away from the machine.

After use maintenance

After use, clean the machine and the tool. Keep it in a safe and dry place. If you are not going to use the machine for an extended period, put anti-corrosion material on the steel parts.

Expect the best, prepare for the worst

Last but not the least. It is always worth, even if just in case, to familiarize yourself with the location of emergency shut-off switches, fire extinguishers, first aid kits, and other safety equipment.

Following these guidelines, will help you prevent accidents and injuries, and ensure a successful outcome. Better safe than sorry.

- ✔ Follow operating procedures

- ✔ Choose a suitable location

- ✔ Inspect equipment

- ✔ Keep work area clean

- ✔ Use Personal Protective Equipment

- ✔ No jewellery and loose elements

- ✔ Stay alert and watch what you are doing