PRO-102: 100mm diameter and 100mm depth capacity

PROMOTECH PRO-102 is a simple yet powerful magnetic drilling machine that enables

precise milling up to 100mm in diameter and depth. A robust 1650W motor and a 4-speed gearbox (100, 175, 275, and 500 rpm) allow users to precisely adjust spindle speeds to suit various diameters and applications.

PROMOTECH PRO-102 is a reliable machine that enables:

- milling up to 100 mm by using annular TCT and 80mm by using HSS cutters

- drilling up to 31.75 mm by using twist drill bits

- pipe drilling with an optional attachment.

Strong, lightweight magnet

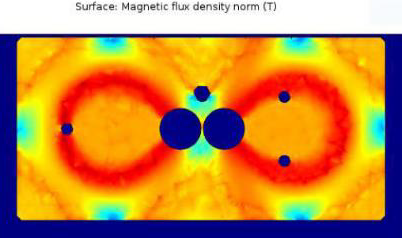

Thanks to an innovative, lightweight smart magnet, the PRO-102 weighs only 24kg and delivers maximum holding power, even on materials as thin as 10mm. The optimized electromagnetic force-to-weight ratio is the result of advanced engineering, achieved through cutting-edge finite element method (FEM) simulations.

A strong dual-coil, CNC-machined 2-way magnet reduces energy consumption, minimizes heat generation, and extends the machine’s lifespan.

Smart safety

PRO-102 comes equipped with intelligent systems to protect both the operator and the machine.

Magnetic Field Shape Control (MFSC) technology maximizes holding force even on thin workpieces, ensuring stability and preventing movement during operation.

Magnetic Power Adhesion Control (MPAC) technology monitors the adhesive force of the electromagnetic base. If the clamping force is too low, the system will not allow the machine to operate, preventing potential accidents and protecting both the user and the machine.

Clamping Force Monitoring System

While the electromagnetic base secures the PRO-102 to ferromagnetic surfaces, external factors can affect its grip. Rust, paint, chips, dirt, a rough, too thin, uneven, or non-rigid surface, insufficient voltage, or base wear can reduce clamping efficiency.

To ensure safe and stable operation, PRO-102 features the clamping force monitoring system that detects any loss of adhesion. Additionally, a safety strap ensures the machine remains secure in case of a clamping failure or power shutdown.

Extending Motor Life with Automatic Motor Shut-off

The PRO-102 automatically shuts off when the carbon brushes are worn out. To restart the motor it is necessary to replace the brushes, preventing motor damage and ensuring timely maintenance.

Optimized Power Usage with Energy-Saving Base (ESB)

Thanks to Energy Saving Base (ESB), the PRO-102 uses only 50% of its power when the motor is not running, significantly reducing energy consumption.

The PRO-102 is not only about power—it’s also designed for ease of use and operator comfort.

Semi-automatic gib adjustment

Designed for efficiency and durability, the PRO-102 allows users to make quick and accurate clearance of backlash with semi-automatic gib adjustment. This unique system enables simple, fast, and always correct fine tuning without any expert knowledge or experience.

3-Spoke Handle for Better Grip

For improved control and comfort, the PRO-102 is equipped with a 3-spoke handle, providing a secure grip and precise depth adjustments. Its ergonomic design minimizes strain, making it comfortable to use even during extended operations.

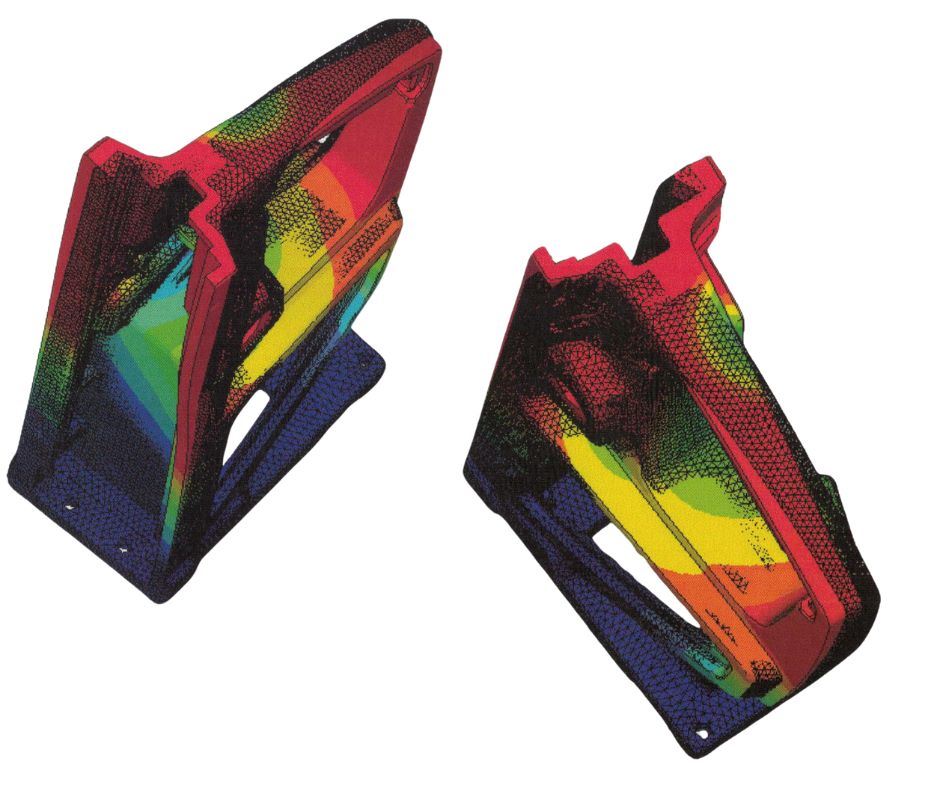

Rigid Construction for Longer Cutter Life

PRO-102 drill housing is engineered using advanced numerical methods, such as Finite Element Analysis (FEA), to optimize structural rigidity and minimize deformations during drilling. The increased housing stiffness reduces unwanted vibrations and stress on cutting tools, extending cutter lifespan and improving user comfort. This reduces the need for frequent replacements and minimizes downtime.

- Improved cutter lifespan

- Improved hole tolerances

- Improved hole surface quality

- Reduced cutter breakage

With its powerful 4-speed motor, ergonomic design, and impressive 100mm diameter and 100mm depth drilling capacity, the PRO-102 magnetic drill is a robust and reliable solution for industrial professionals seeking long-term performance and durability.