JTS | Automatic Joint Tracking System

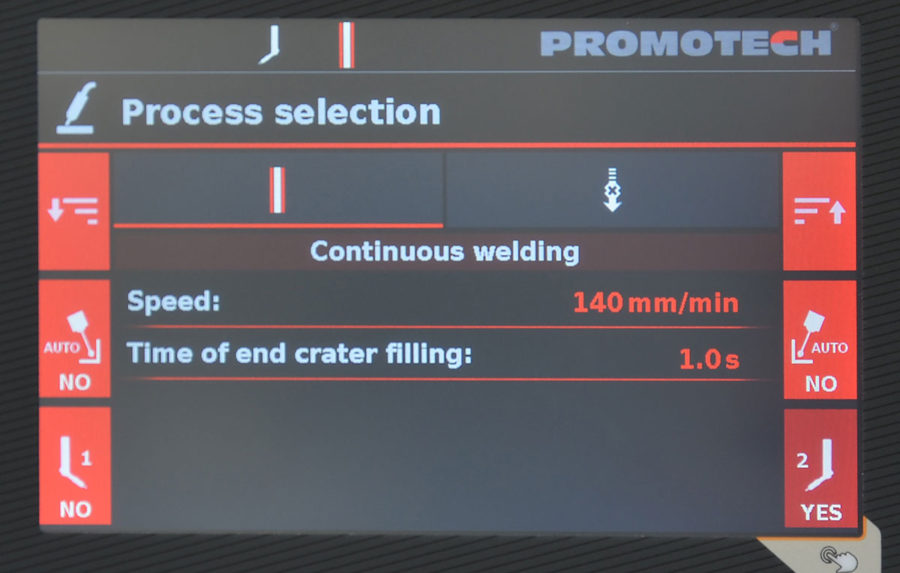

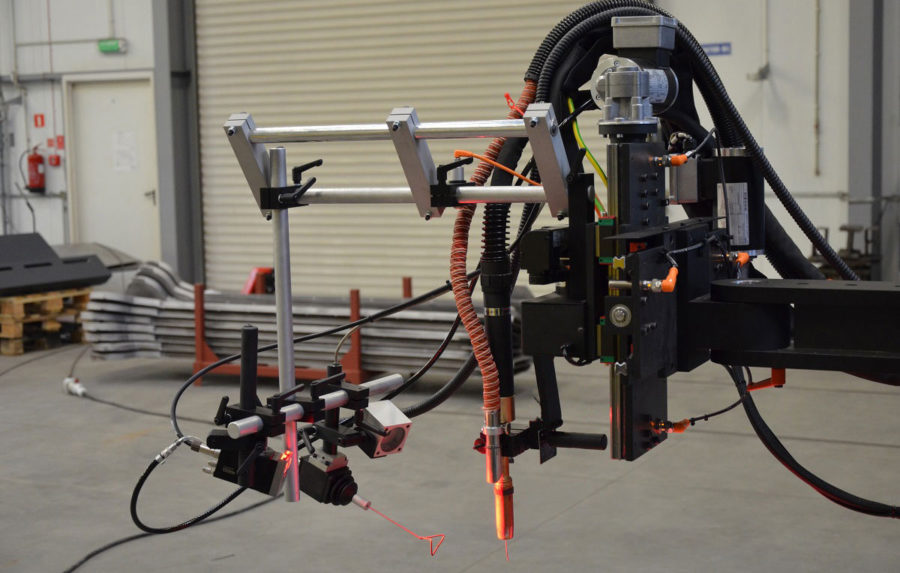

The Joint Tracking System automatically guides the welding torch accurately with respect to the weld joint along two axes. It is suitable for GMAW, GTAW, FCAW, and SAW applications and can be fitted to column and boom welding manipulators, gantry welding systems, and other purpose-designed welding systems.

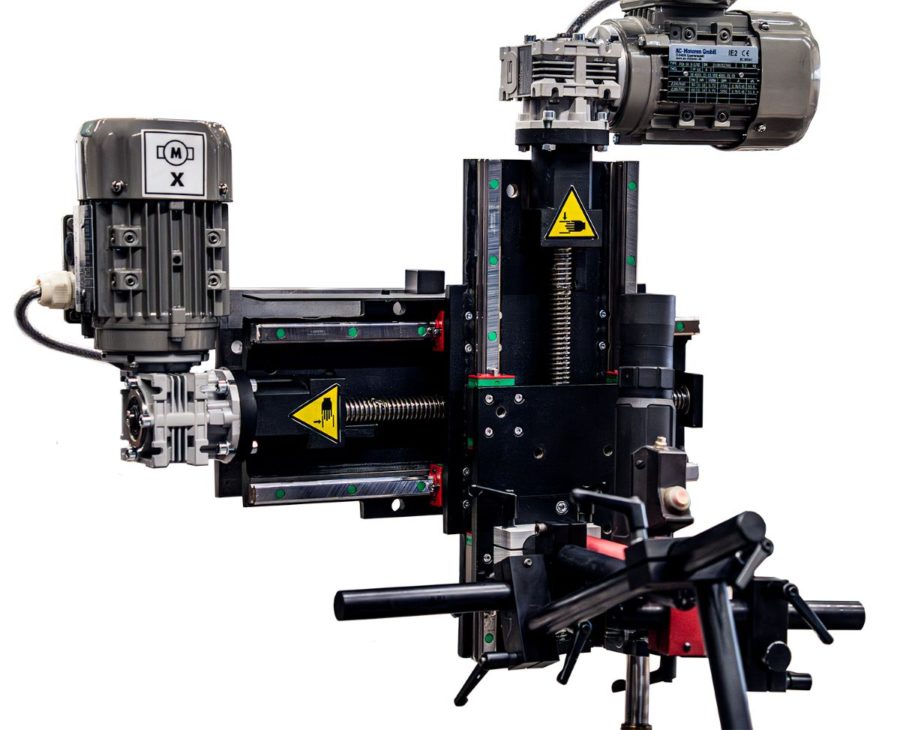

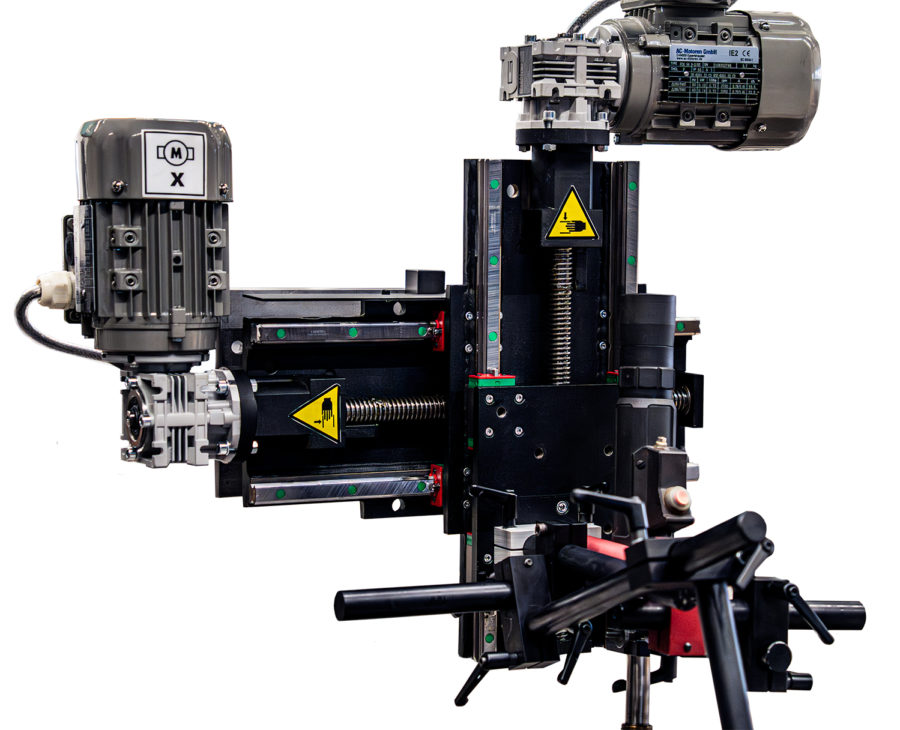

The electro-mechanical seam tracking system maintains the correct position of the welding torch relative to the welding groove established at the start. Any changes in the inclination of the tracking sensor tip generate an electrical signal, resulting in active compensation of the torch position and its movement, up to 200 mm in both axes of a standard motorized cross-slide system. The movement range can be customized upon customer request.

- Standard movement range: 200 x 200 mm.

- An electromechanical joint tracking system with high-precision linear guides ensures accurate and smooth motion in two axes (up-down, right-left).

- Real-time compensation of head position relative to the welding groove.

- Minimizes welding defects and reduces grinding requirements.

- Cross slide can be customized to meet customer specifications.

- Equipped with a user-friendly control pendant.