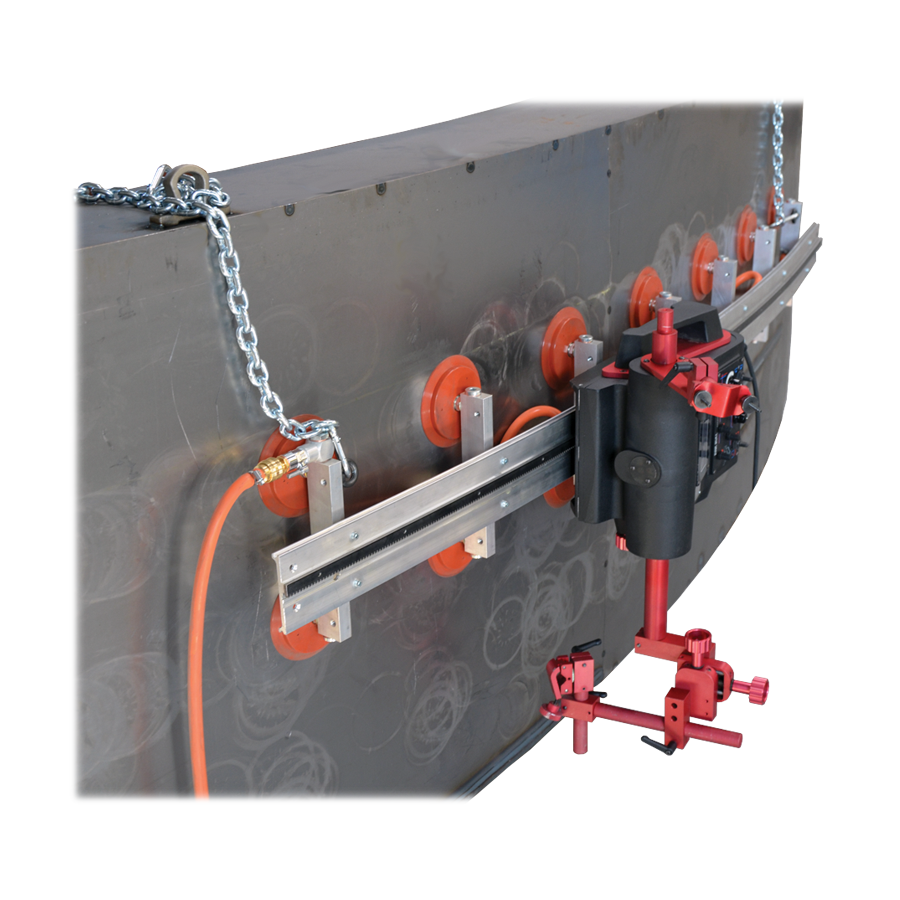

Vacuum Track System

Promotech’s vacuum fixing system provides firm grip of rail tracks on both ferromagnetic and non-ferromagnetic materials. Lightweight and modular design enables easy adjustment and fitting of the system to specific needs depending on welding or cutting applications and working positions (e.g. flat, horizontal, or vertical). A vacuum fixing system can be applied to both rigid and semi-flexible tracks to enable usage on surfaces with a radius of more than 5 m (16 ft).

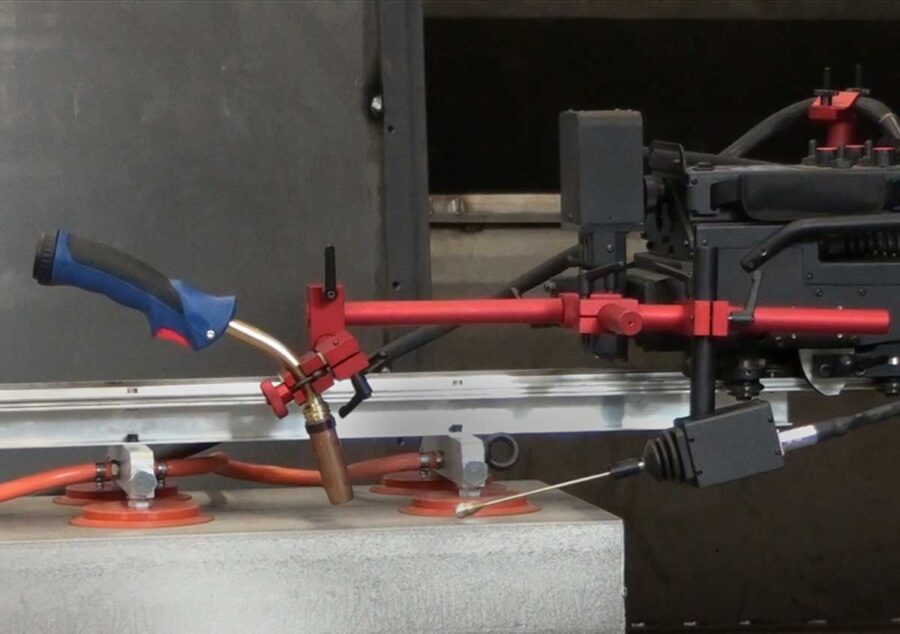

- Back up a reservoir for added safety in case of a power failure; a back up vacuum offers additional time to safely secure

- A welding tractor and tracks; also greatly reduces the installation time of the whole system

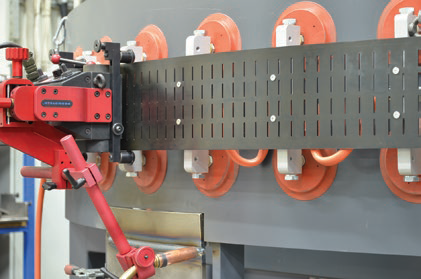

- Maximum plate temperature up to +320°C (608°F)

- Only 100 mm (4”) minimal distance from the heat source to the vacuum pads