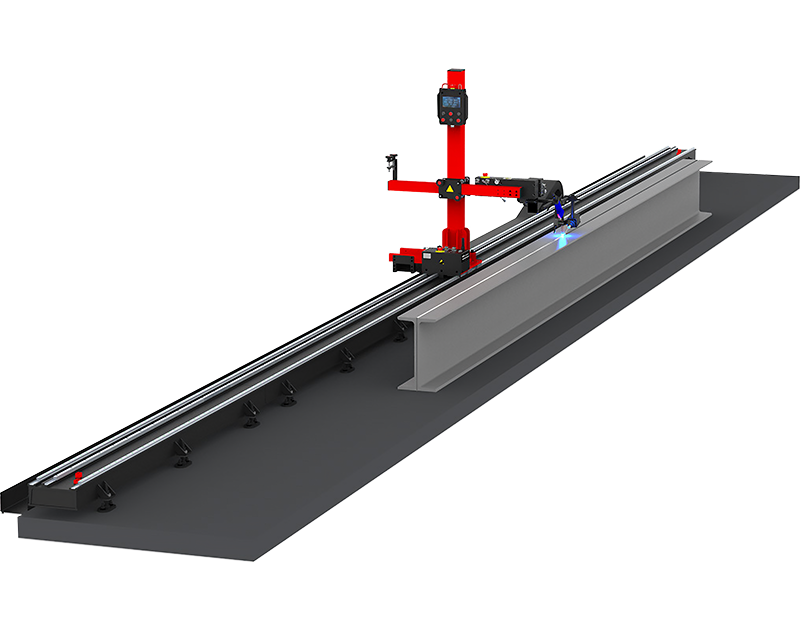

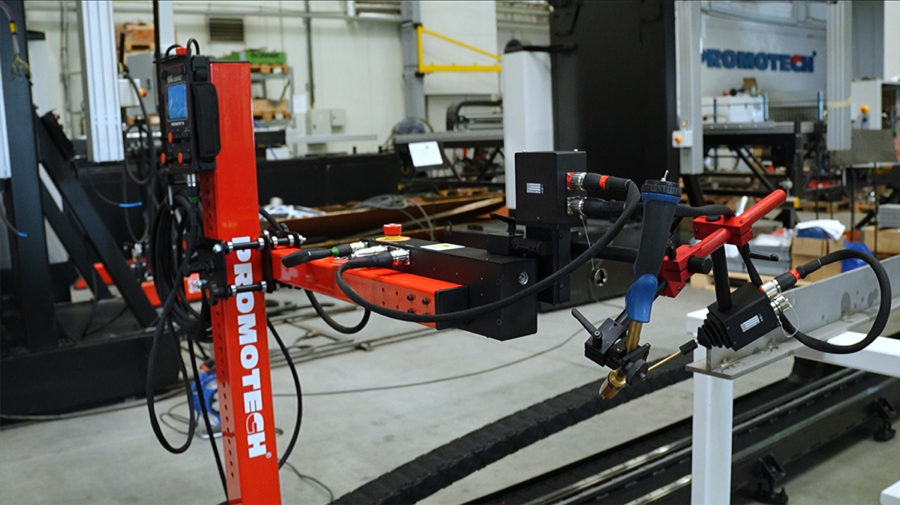

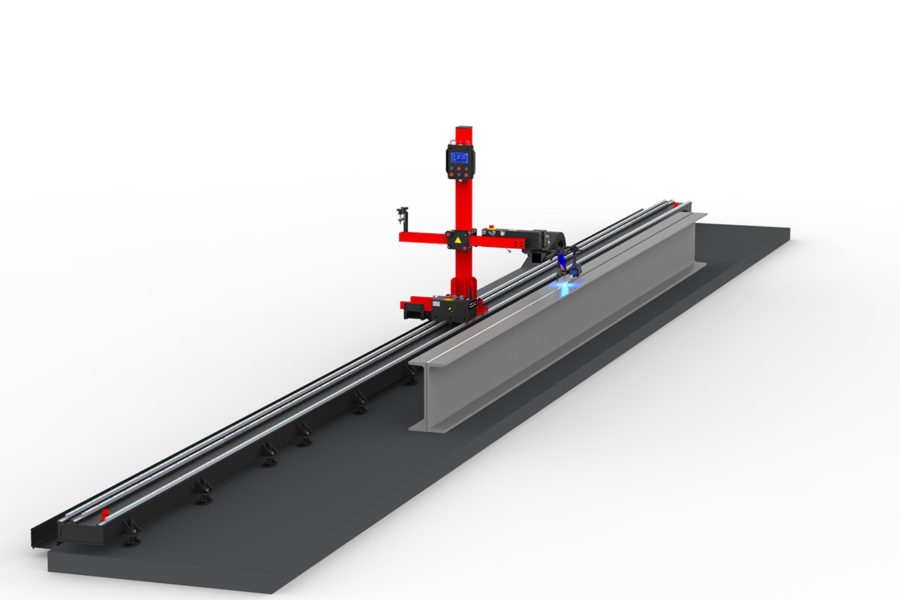

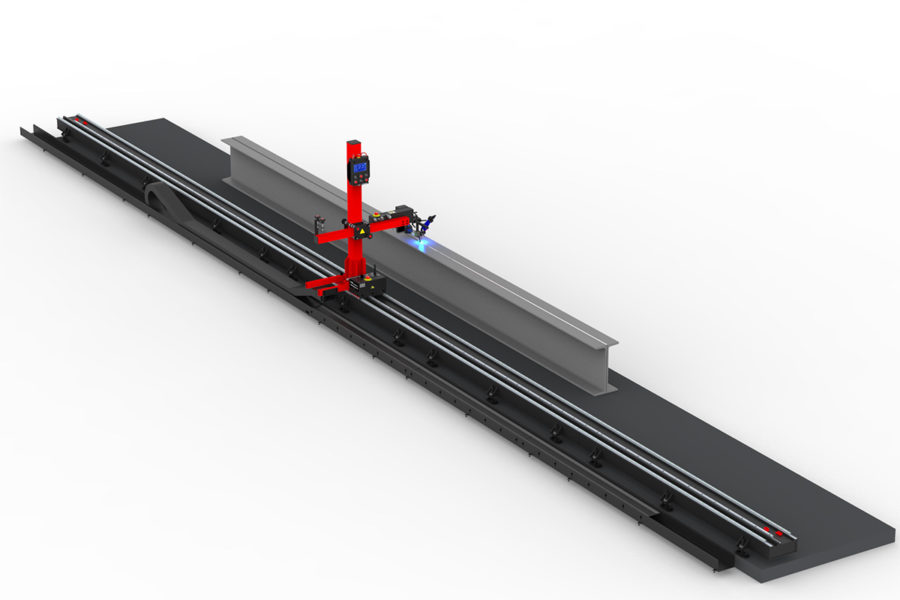

WA Compact | Welding System

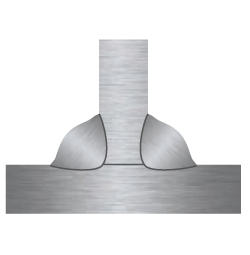

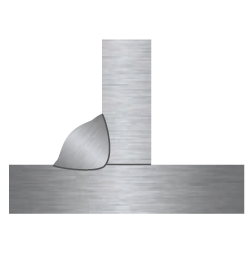

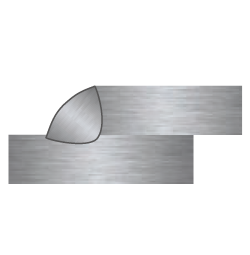

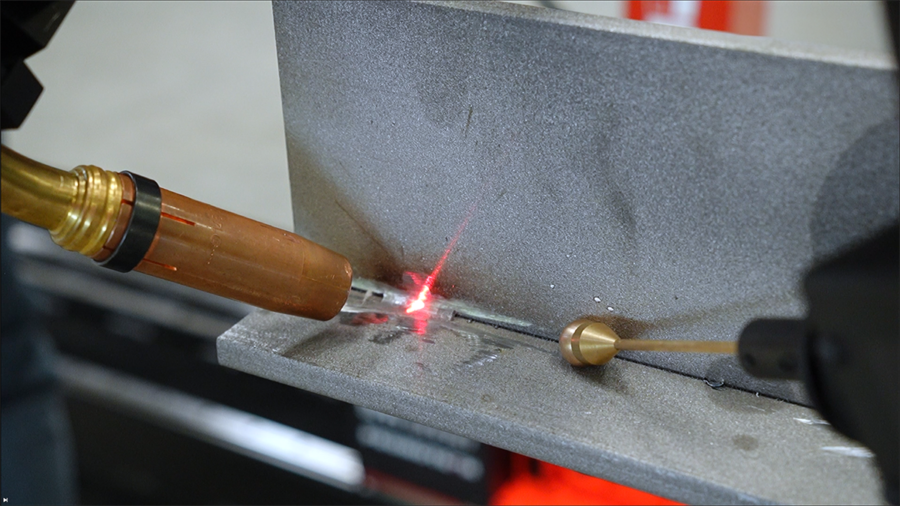

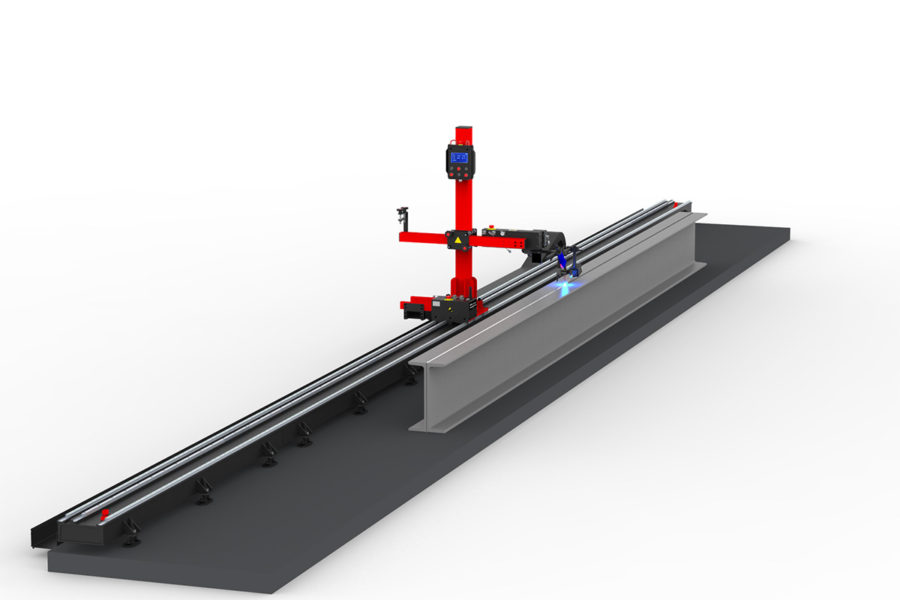

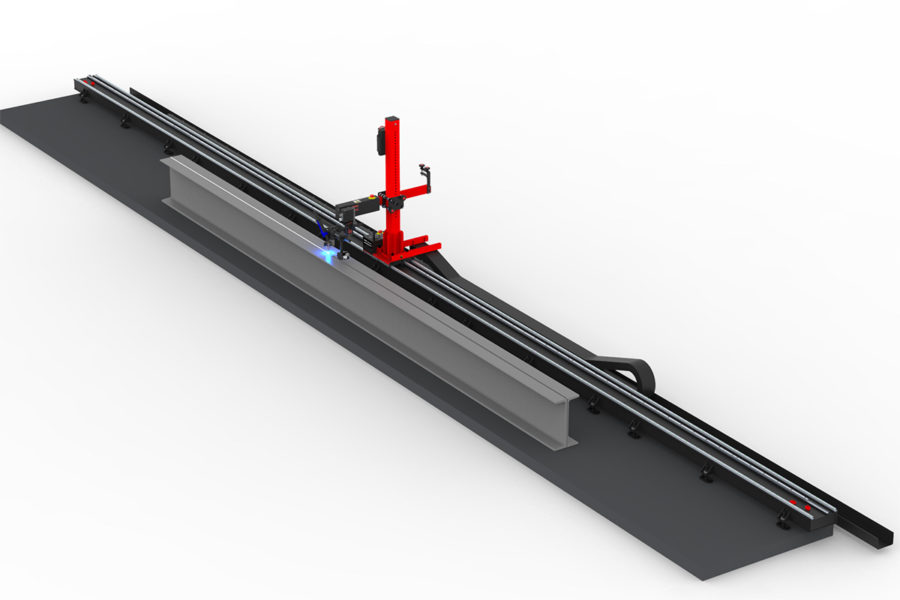

The WA Compact Welding System is an advanced and versatile welding solution designed for making both continuous and stitch butt and fillet welds using the MIG/MAG method. The system provides efficient joint tracking for active compensation of torch position vertically and horizontally with and without oscillation. WA Compact supports welding with different oscillation patterns, including straight, triangle, trapezoid, and square, enhancing its adaptability to various welding tasks. It is ideally suited for industrial applications, providing an efficient and budget-friendly option for workshops and large industrial plants.

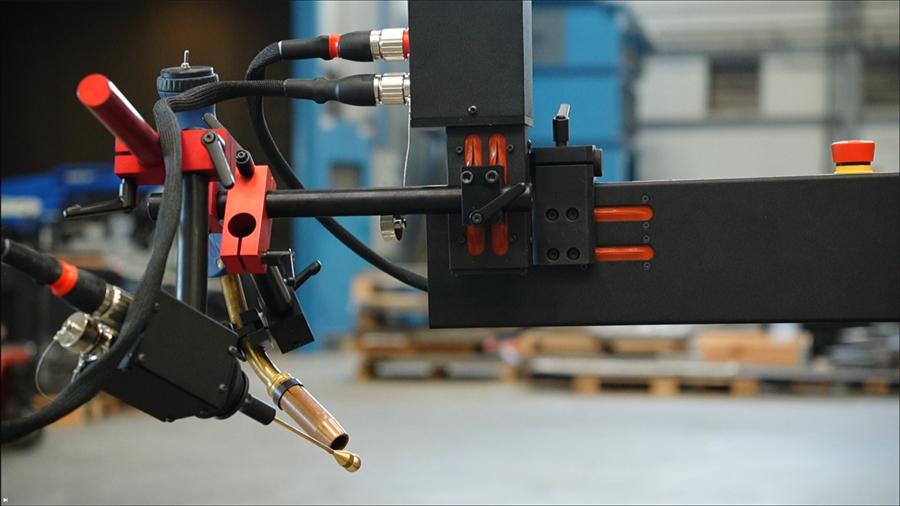

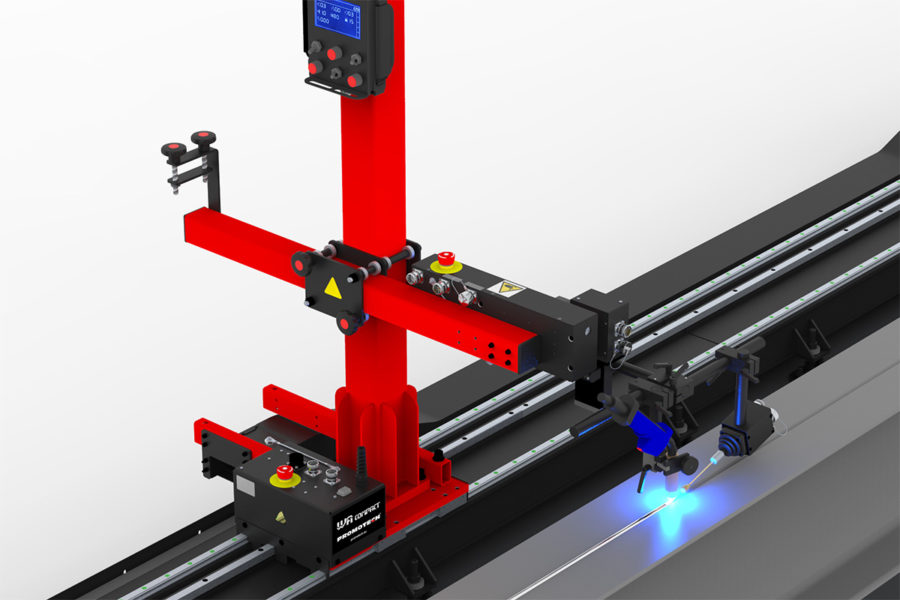

- Advanced Welding Capabilities: Supports continuous and stitch welding using MIG/MAG method, ensuring versatility in different welding tasks.

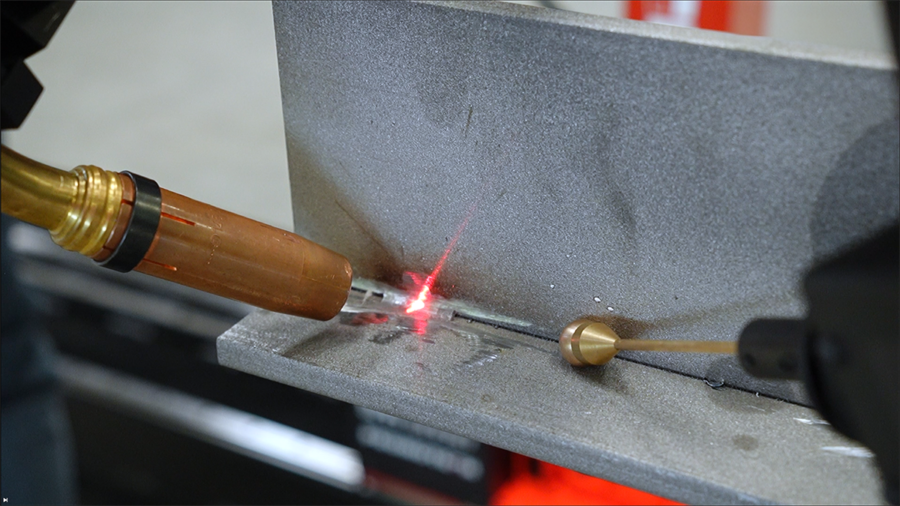

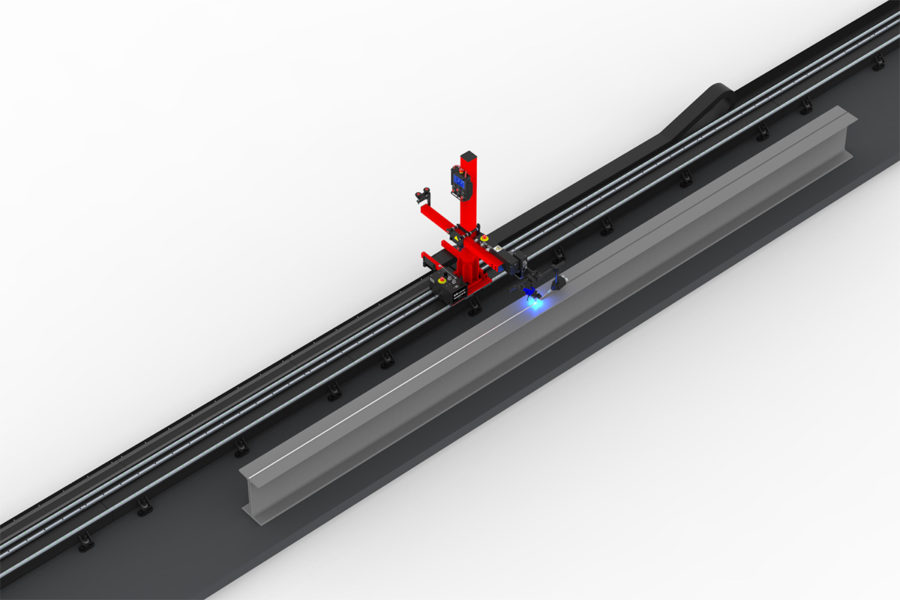

- Precision and Efficiency: Equipped with oscillation and joint tracking with motorized vertical slide, maintaining the correct torch position for high-quality welds.

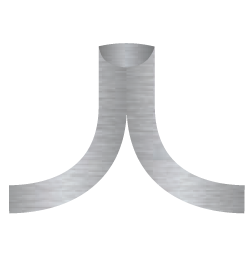

- Flexible Oscillation Patterns: Offers weld paths such as straight, triangle, trapezoid, and square, increasing adaptability to different requirements.

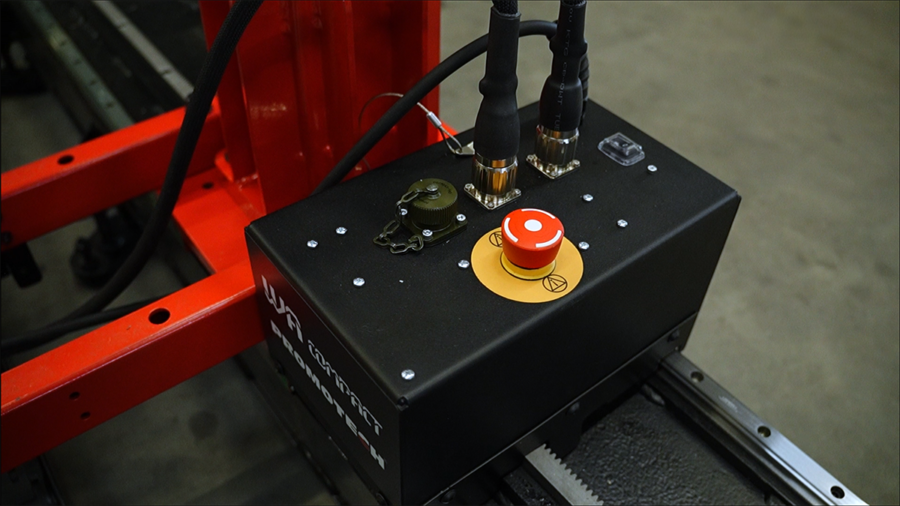

- User-Friendly Control: Ergonomic remote control pendant with simple and easy to find control knobs makes adjustments possible without lifting the operator’s welding hood

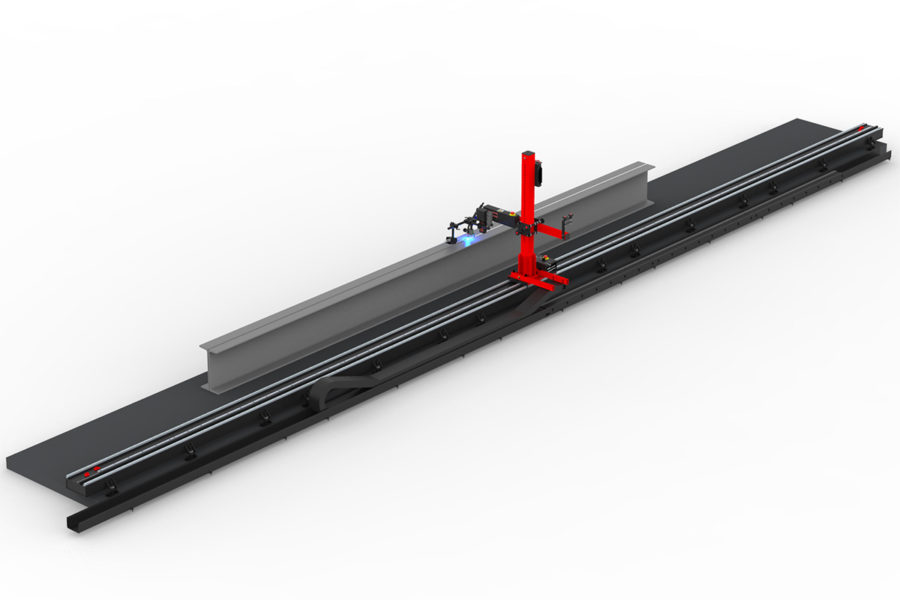

- Custom Track Length: Track sections consist of 2 m support segments. The total length of the track can be tailored to the customer’s requirements.

- Cost-Effective Solution: Budget-friendly advanced and versatile welding solution with customized workspace, making it a practical choice for both workshops and large industrial facilities